Bacillus subtilis, compound microbial agent, organic matrix and preparation and application thereof

A technology of compound microbial agent and Bacillus subtilis, which is applied in the preparation of organic fertilizers, treatment of bio-organic parts, microorganisms, etc., can solve the problem of ineffective composting by microorganisms, and achieve shortened compost maturity time and strong tolerance , Increase the effect of water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1 Acquisition, Identification and Preservation of Bacillus subtilis

[0071] The present invention obtains a strain of Bacillus subtilis BS-W1 from livestock and poultry feces high-temperature composting raw materials. The strain has been preserved in the China Center for Type Culture Collection on October 19, 2017, and the preservation number is CCTCC M 2017589.

[0072] The bacillus subtilis isolated in the invention can withstand high temperature composting environment (70°C). And it can secrete a variety of enzymes to efficiently degrade compost materials such as manure and straw.

[0073] After morphological identification and 16S rRNA, ITS-2 and rbcL amplified sequence developmental tree analysis, it was determined that the strain was Bacillus subtilis (according to the international naming rules: genus name + species name + strain name to name the strain, genus name, The species name and strain name are respectively Bacillus, subtilis and BS-W1), named B...

Embodiment 2

[0074] Example 2 Composite microbial bacterial agent for high-temperature aerobic composting

[0075] The Bacillus subtilis BS-W1 of the invention can be used for high-temperature aerobic composting. Generally, it is formulated with other microorganisms into a composite microbial agent for high-temperature aerobic composting.

[0076] The range of parts by weight between the components in the composite microbial agent 1 is: 1 part by weight of Bacillus subtilis, 5 parts by weight of Aspergillus niger, 1 part by weight of Bacillus amyloliquefaciens, 5 parts by weight of Candida tropicalis, 1 part by weight of Trichoderma, 3 parts by weight of Streptomyces grisea, 1 part by weight of Phanerochaete chrysosporium, 3 parts by weight of Pseudomonas fluorescens, 1 part by weight of Lactobacillus brevis, and 3 parts by weight of Bacillus longum. .

[0077] The range of parts by weight between the components in the composite microbial agent 2 is: 5 parts by weight of Bacillus subtili...

Embodiment 3

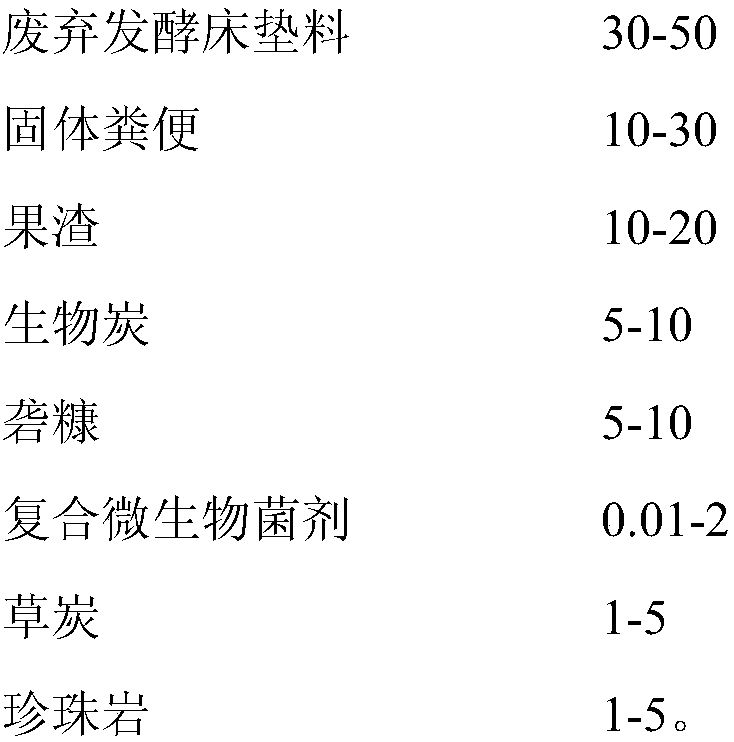

[0087] Example 3 Preparation of organic matrix using cattle waste and apple pomace

[0088] Organic matrix formula in the present embodiment:

[0089] The parts by weight of each raw material are: 30 parts by weight of waste cattle breeding fermented bedding material, 30 parts by weight of cow solid manure, 20 parts by weight of apple pomace, 8 parts by weight of biochar, 6 parts by weight of rice bran, 3 parts by weight of peat, pearl 3 parts by weight of rock, and 1 part by weight of composite microbial bacterial agent is added to ferment. The composition and parts by weight of the composite microbial bacterial agent in the present embodiment are: 3 parts of Bacillus subtilis, 5 parts of Aspergillus niger, 3 parts of Bacillus amyloliquefaciens, 3 parts of Candida tropicalis, 3 parts of Trichoderma reesei, 1 part of Streptomyces rubrum, 3 parts of Phanerochaete chrysosporium, 1 part of Pseudomonas fluorescens, 1 part of Lactobacillus brevis, and 1 part of Bacillus longum.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com