Method for improving binding force and tribological property of fullerene-like thin film

A fullerene-like, binding force technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of high friction coefficient of fullerene-like films, complicated process, and ineffective improvement of binding force, etc. problems, achieve good chemical inertness, simple process, and improve tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First, select three stainless steel sheets with a smooth surface, pre-clean them with dilute hydrochloric acid solution, wait for them to dry, then put them into acetone and ethanol for ultrasonic cleaning for 30 minutes each, take out the stainless steel sheets, dry them with ear washing balls, and then quickly transfer them to On the base of the vacuum chamber, start vacuuming. Secondly, wait for the vacuum to be less than 1.0×10 -3 At Pa, argon gas (150 SCCM) was introduced, and the pressure was adjusted to about 25 Pa. Under the condition of pulse bias of -600 V and duty cycle of 50%, plasma cleaning was performed for 30 minutes. After the cleaning is completed, a mixture of nitrogen (30 SCCM), phosphine (10 SCCM) and methane (10 SCCM) is introduced, and the pressure is adjusted to about 35 Pa. The fullerene-like thin film was deposited at low temperature under the condition of 2 hours.

Embodiment 2

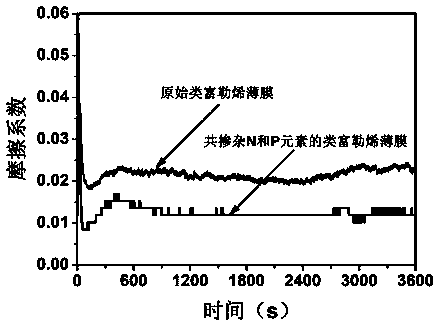

[0029] First, two silicon wafers with smooth surfaces are selected, one of which is deposited on the surface of a fullerene-like film co-doped with N and P elements, and the other is deposited on the surface of a fullerene-like film not doped with N and P elements. Then the friction test was carried out on the two silicon substrates with carbon film deposited on the surface. The test conditions are: dual ball 6 mm steel ball, load 10 N, frequency 3 Hz, amplitude 5 mm, time 1 hour. as figure 1 As shown, the average friction coefficient of the fullerene-like film co-doped with N and P elements is 0.012, while the average friction coefficient of the fullerene-like film without N and P elements is 0.021. The experiment was repeated three times to ensure the accuracy of the experimental results. It shows that the fullerene-like film co-doped with N and P elements can greatly reduce the friction force, and the friction force drops by about 43%.

Embodiment 3

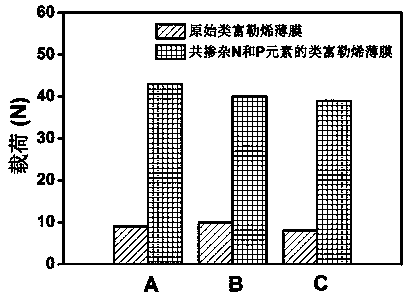

[0031] First, two stainless steel sheets with smooth surfaces are selected, one of which is deposited on the surface of a fullerene-like film co-doped with N and P elements, and the other is deposited on the surface of a fullerene-like film not doped with N and P elements. Then the scratch test was carried out on the two silicon substrates with carbon film deposited on the surface. as figure 2 As shown, the binding force of the fullerene-like film co-doped with N and P elements is 40 N, while the binding force of the fullerene-like film without N and P elements is 10 N. Repeat the experiment three times to ensure the accuracy of the experimental results. It shows that the fullerene-like film co-doped with N and P elements can improve the binding force between the substrate and the fullerene-like film, and the binding force can be increased by 300%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com