Novel aluminum nitride self-seeding nucleation growth method

A growth method and technology of aluminum nitride, applied in the field of new aluminum nitride self-nucleation growth, can solve problems such as large internal stress, thermal mismatch, and substrate seed crystal lattice mismatch, and achieve simple and repeatable implementation. High, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

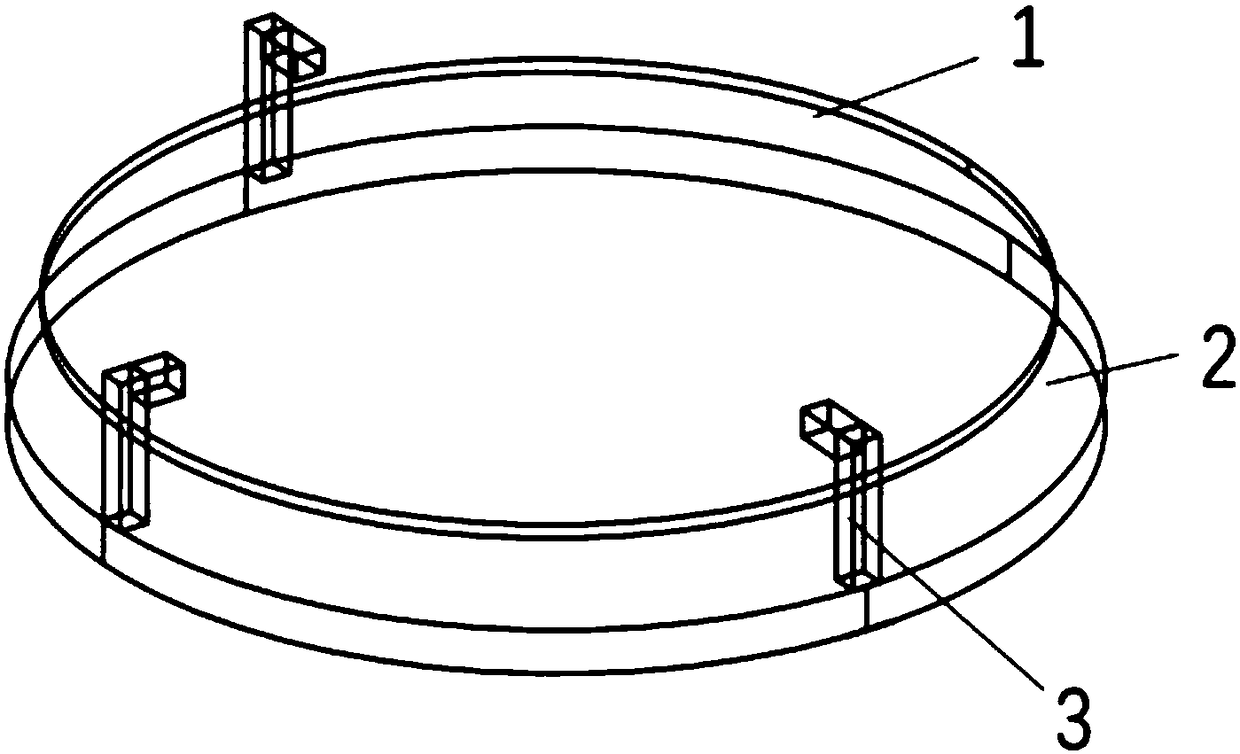

[0036] like Figure 1-2 As shown, (1) aluminum nitride is made of powder with a purity of 99.7%, and a single-chip insulating layer 1 with a thickness of 50-100 μm is used as a protective layer, and the tantalum carbide seed crystal cover 2 and the aluminum nitride source are covered by silicon carbide. 8 for isolation. Avoid nucleation of aluminum nitride on the tantalum carbide seed cap 2 in the early stage. The single-wafer isolation layer 1 is fixed on the aluminum nitride source 8 through the three-point support clamping structure 3 .

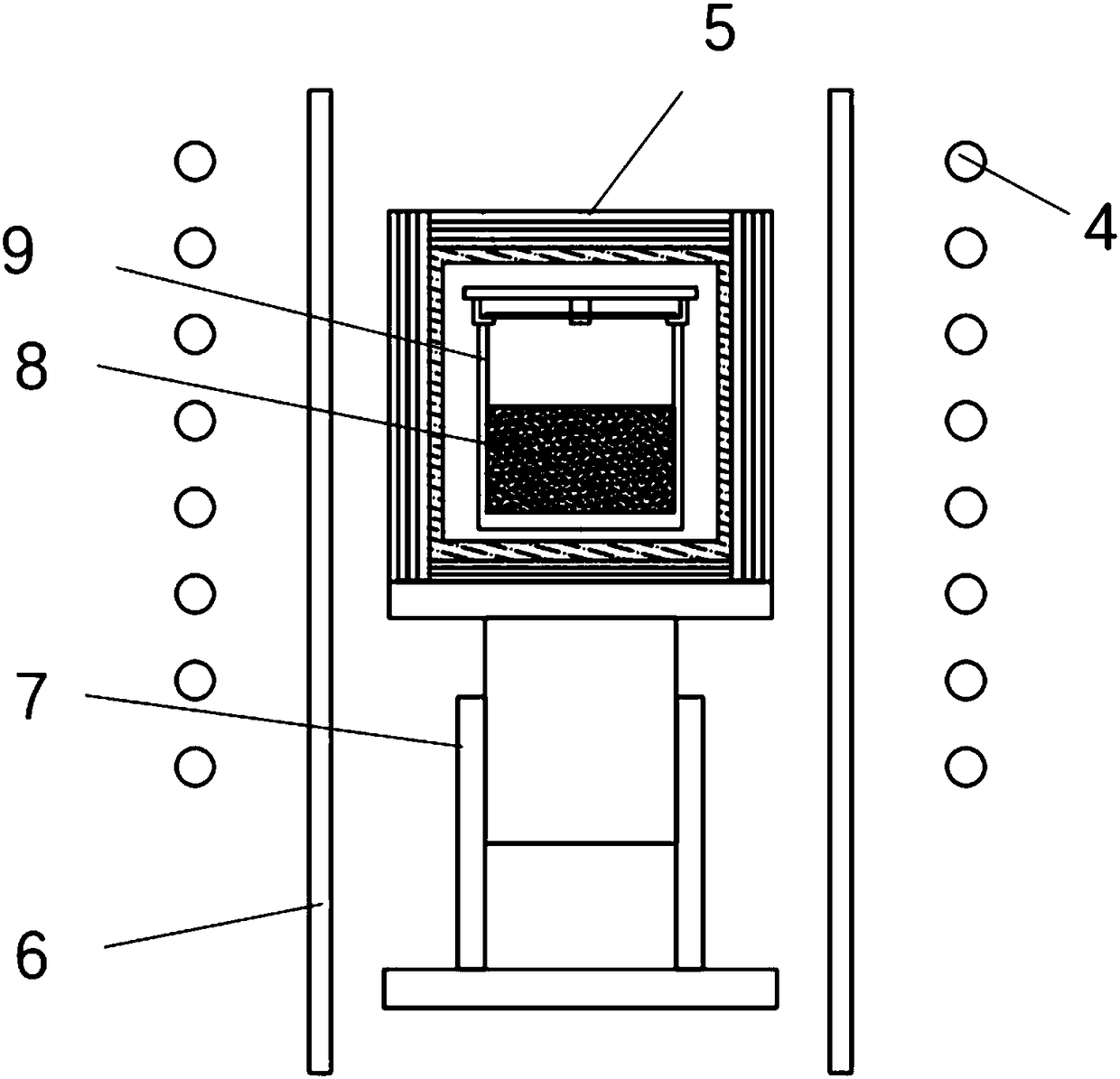

[0037] (2) Put the sintered aluminum nitride material source 8 in the crucible, and the crucible is placed in the quartz casing 6. According to the crystal growth simulation results, determine the material spacing to be 90-100 mm, and adjust the TaC crucible 9 relative to the induction coil 4 The position is so that the coil heating induction high temperature position is on the upper surface of the material source. Control the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com