Power distribution box

A technology of power distribution box and distribution box, which is applied in electrical components, substation/switch layout details, etc., can solve the problems of poor electromagnetic shielding performance and the insulation performance needs to be improved, so as to improve the wear resistance and tear resistance performance, raw materials Low cost and good electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A power distribution box, which includes a box, and the box is prepared according to the following process:

[0018] Add brucite to the crusher in turn for crushing, then mix it evenly with quartz sand at a mass ratio of 1:1, and then grind to obtain a powder with a particle size of 20 microns, which is the material 1;

[0019] Mix diatomaceous earth and kaolin according to the mass ratio of 2:1, then calcinate at 700°C for 10 minutes, then take it out and pulverize to obtain material 2;

[0020] Molybdenum disulfide and graphite were mixed according to a mass ratio of 2:1 to obtain a mixture, then added to N-methylpyrrolidone accounting for twice the weight of the mixture, and stirred at 300 rpm for 5 minutes to obtain material 3;

[0021] Take wood powder, phenolic resin, polyvinyl alcohol, glass fiber, white oil and carbon fiber, put them into the reaction kettle, mix well, then raise the temperature to 90°C, keep it warm for 3 minutes, cool naturally, then add mater...

Embodiment 2

[0024] A power distribution box, which includes a box, and the box is prepared according to the following process:

[0025] Add brucite to the crusher in turn for crushing, then mix it evenly with quartz sand in a mass ratio of 1:1, and then grind it to obtain a powder with a particle size of 100 microns, which is the material 1;

[0026] Mix diatomaceous earth and kaolin according to the mass ratio of 2:1, then calcinate at 800°C for 10 minutes, then take it out and pulverize to obtain material 2;

[0027] Molybdenum disulfide and graphite were mixed according to a mass ratio of 2:1 to obtain a mixture, then added to N-methylpyrrolidone accounting for twice the weight of the mixture, and stirred at 300 rpm for 5 minutes to obtain material 3;

[0028] Take wood powder, phenolic resin, polyvinyl alcohol, glass fiber, white oil and carbon fiber, put them into the reaction kettle, mix well, then raise the temperature to 90°C, keep it warm for 3 minutes, cool naturally, then add m...

Embodiment 3

[0031] Box material performance test of the present invention:

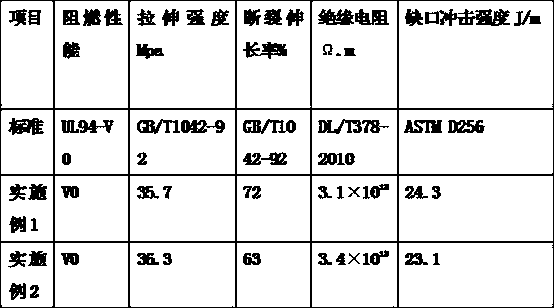

[0032] 1. The box body material prepared in embodiment 1-2 is made standard test piece by test standard, carries out following performance test, and the results are shown in Table 1:

[0033] Table 1

[0034]

[0035] Anti-radiation performance: After testing, the shielding rate of the box material to X-rays and ultraviolet rays can reach more than 80%.

[0036] Corrosion resistance: soak the cabinet material in 10% dilute hydrochloric acid solution or 6% sodium hydroxide solution for 360 hours, there is no obvious change in appearance and performance parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap