3D biological protein and preparation method and applications thereof

A biological protein, 3D technology, applied in the field of 3D biological protein and its preparation, can solve the problems of affecting the experimental effect, porosity and hardness, and large pores of 3D biological protein.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a 3D biological protein in one embodiment includes the following steps S110-S120.

[0031] S110, mixing the fluorescein-labeled albumin and the photosensitizer to obtain a mixed solution.

[0032] In one embodiment, in the fluorescein-labeled albumin, the fluorescein is selected from at least one of FITC (fluorescein isothiocyanate) and PE (phycoerythrin). The albumin is at least one selected from bovine serum albumin (BSA), human serum albumin (HSA), human recombinant serum albumin, sheep serum albumin and rabbit serum albumin.

[0033] In one embodiment, the photosensitizer is rose bengal sodium salt (RB).

[0034] Specifically, the final concentration of fluorescein-labeled albumin in the mixed solution is 50 mg / mL-100 mg / mL. The final concentration of the photosensitizer is 0.05w / v%-0.15w / v%.

[0035] Specifically, w / v% represents the mass-to-volume ratio, that is, the final concentration of the photosensitizer in the mixed solution is 0.5g...

Embodiment 1

[0063] Mix FITC-BSA and RB photosensitizer, and add a certain amount of pure water to prepare a mixed solution. The final concentration of FITC-BSA in the mixed solution is 100mg / mL, and the final concentration of RB photosensitizer is 0.1w / v%.

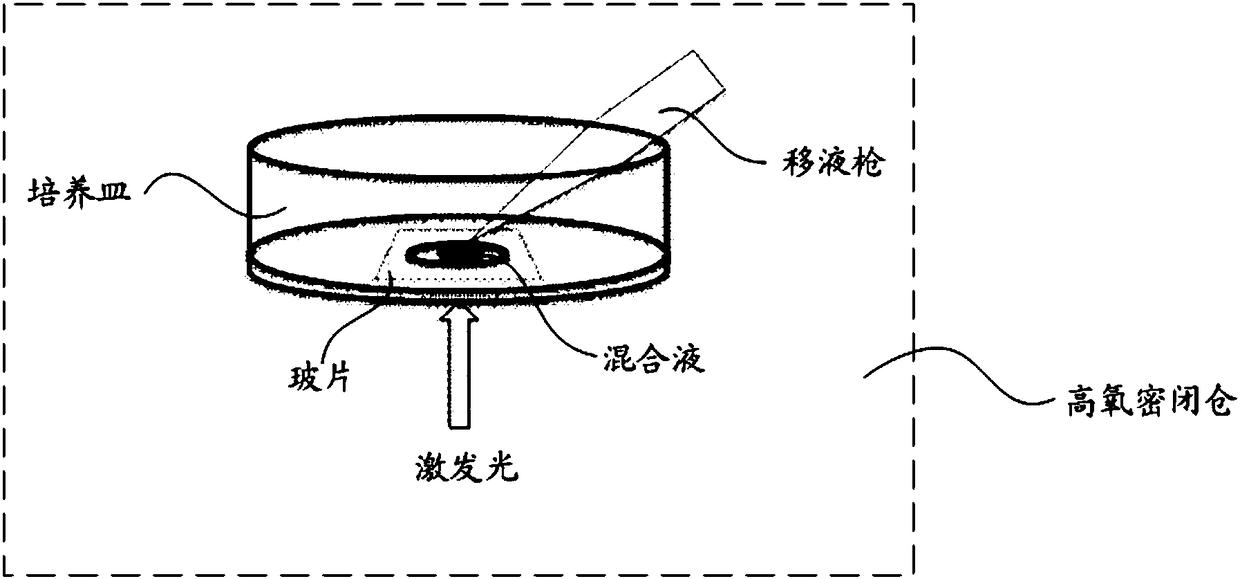

[0064] See figure 1 , place a glass slide in a Petri dish, and drop 100 μL of the above mixture onto the glass slide through a pipette gun. Then the culture dish is moved into the high oxygen airtight chamber, and the oxygen partial pressure in the high oxygen airtight chamber is set to be 0.3Kpa, the oxygen concentration to be 75%, and the humidity to be 60%. A 40× oily objective lens was used, and a two-photon exciter was used to scan the mixture layer by layer in a high-oxygen airtight chamber to solidify the mixture. The wavelength of the excitation light is set to 700nm, the energy is 20mW, and the area of each laser beam scanning section is 1μm 2 . The laser penetrates the slide into the mixture, and scans upward layer by l...

Embodiment 2

[0066] Mix FITC-BSA and RB photosensitizer, and add a certain amount of pure water to prepare a mixed solution. The final concentration of FITC-BSA in the mixed solution is 75mg / mL, and the final concentration of RB photosensitizer is 0.15w / v%.

[0067] See figure 1 , place a glass slide in a Petri dish, and drop 100 μL of the above mixture onto the glass slide through a pipette gun. Then move the petri dish into the high oxygen airtight chamber, set the oxygen partial pressure in the high oxygen airtight chamber to be 0.35Kpa, the oxygen concentration to be 80%, and the humidity to be 70%. The mixed solution is scanned layer by layer in the oxygen-tight chamber to solidify the mixed solution. The wavelength of the excitation light is set to 750nm, the energy is 10mW, and the area of each laser scanning section is 0.8μm 2 . The laser penetrates the slide into the mixture, and scans upward layer by layer from the surface of the slide (the liquid bottom of the mixture). Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com