Method for preparing sulfur-doped graphene-like mesoporous carbon nano-material

A carbon nanomaterial and ene mesoporous technology, which is applied in the field of preparing graphene-like carbon nanomaterials, can solve the problems of complicated preparation steps, no cost advantage, a large number of chemical reagents, etc., and achieves strong controllability, easy purification, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described further below in conjunction with example, but the present invention is not limited to specific embodiment.

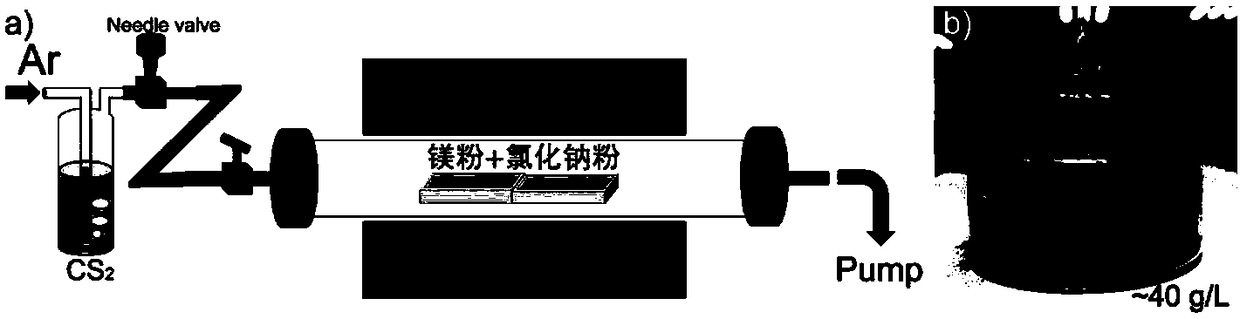

[0022] 1) Weigh 8 grams of magnesium powder and 42 grams of NaCl powder, mix them with a shaker in a plastic test tube, and then pour them into two large-sized corundum boats.

[0023] 2) Put the two ceramic boats containing the reactants into the furnace tube, pump air with a mechanical vacuum pump, and then fill it with argon, repeat twice to remove oxygen.

[0024] 3) Introduce argon gas into the liquid carbon disulfide container, and bubble the liquid at a flow rate of 200mL / min, Ar and CS 2 The mixed gas is passed into the tube furnace. At the same time, the furnace was heated up to 600°C at a rate of 15°C and held for 90 minutes. During the reaction, the tube furnace was pumped with a vacuum pump.

[0025] 4) After the reaction, the furnace was naturally cooled to room temperature, and the ceramic boat was taken out an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com