Device for treating rare earth producing ammonia nitrogen wastewater through combination of microwave and supergravity and application method

A technology for combined treatment of ammonia nitrogen wastewater, applied in chemical instruments and methods, water/sewage treatment, heating water/sewage treatment, etc., can solve the high cost of phosphate by chemical precipitation method, high cost of ammonia distillation and concentration method, and difficulty in product sales and other problems, to achieve the effect of reducing energy consumption, high ammonia stripping rate, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

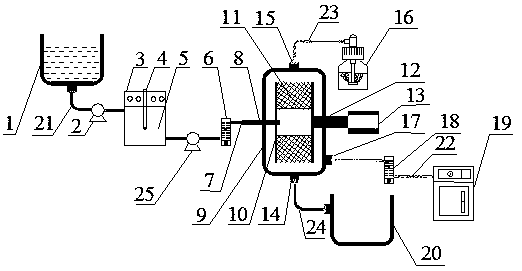

[0026] Such as figure 1 As shown, the microwave-high gravity combined treatment device for ammonia nitrogen wastewater produced by rare earth includes a waste water tank 1, an infusion pump, a microwave oven 3, a water spray pipe 8, a high gravity rotating packing bed 9, a rotating disk 10, a mesh belt 11, and a rotating pump 12. Motor 13, liquid outlet 14, gas outlet 15, exhaust gas absorption bottle 16, air inlet 17, blower 19, absorption liquid tank 20, infusion tube 21, air intake tube 22, air outlet tube 23 and liquid outlet tube 24, waste water tank 1 The bottom is connected to the liquid inlet of the microwave oven 3 through the infusion pump (infusion pump I2) and the infusion tube 21, and the heated liquid outlet at the bottom of the microwave oven 3 is connected to the middle position of the side of the high-gravity rotary packed bed 9 through the infusion pump (infusion pump II 25) and the infusion tube 21 Water spray pipe 8, rotating disk 10 is arranged inside supe...

Embodiment 2

[0036] Such as figure 1As shown, the microwave-high gravity combined treatment device for ammonia nitrogen wastewater produced by rare earth includes a waste water tank 1, an infusion pump, a microwave oven 3, a water spray pipe 8, a high gravity rotating packing bed 9, a rotating disk 10, a mesh belt 11, and a rotating pump 12. Motor 13, liquid outlet 14, gas outlet 15, exhaust gas absorption bottle 16, air inlet 17, blower 19, absorption liquid tank 20, infusion tube 21, air intake tube 22, air outlet tube 23 and liquid outlet tube 24, waste water tank 1 The bottom is connected to the liquid inlet of the microwave oven 3 through the infusion pump (infusion pump I2) and the infusion tube 21, and the heated liquid outlet at the bottom of the microwave oven 3 is connected to the middle position of the side of the high-gravity rotary packed bed 9 through the infusion pump (infusion pump II 25) and the infusion tube 21 Water spray pipe 8, rotating disk 10 is arranged inside super...

Embodiment 3

[0044] Such as figure 1 As shown, the microwave-high gravity combined treatment device for ammonia nitrogen wastewater produced by rare earth includes a waste water tank 1, an infusion pump, a microwave oven 3, a water spray pipe 8, a high gravity rotating packing bed 9, a rotating disk 10, a mesh belt 11, and a rotating pump 12. Motor 13, liquid outlet 14, gas outlet 15, exhaust gas absorption bottle 16, air inlet 17, blower 19, absorption liquid tank 20, infusion tube 21, air intake tube 22, air outlet tube 23 and liquid outlet tube 24, waste water tank 1 The bottom is connected to the liquid inlet of the microwave oven 3 through the infusion pump (infusion pump I2) and the infusion tube 21, and the heated liquid outlet at the bottom of the microwave oven 3 is connected to the middle position of the side of the high-gravity rotary packed bed 9 through the infusion pump (infusion pump II 25) and the infusion tube 21 Water spray pipe 8, rotating disk 10 is arranged inside supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com