Polymer containing diaminotriazine and preparation method thereof

A diaminotriazine, polymer technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as poor compatibility and low conversion rate, and achieve compatibility Good, low toxicity, good migration resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

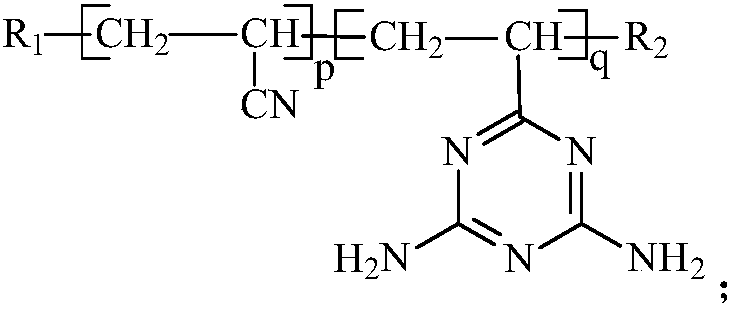

[0050] A kind of preparation method of the polymkeric substance containing diaminotriazine, the steps are as follows:

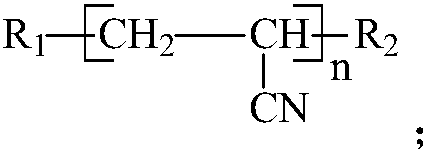

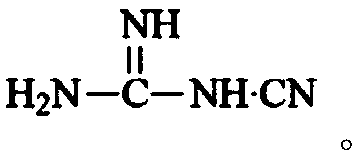

[0051] (1) After mixing polyacrylonitrile, dicyandiamide (structural formula as shown in formula (II)), methanol and calcium chloride, first react at 60°C for 1 hour, then at 80°C for 2 hours, and finally at 100°C ℃ reaction for 1 hour, the product a was obtained by cooling down, wherein the mass ratio of polyacrylonitrile, dicyandiamide and methanol was 1:0.1:5, and the addition of calcium chloride was the addition of polyacrylonitrile in parts by weight. 0.5% of the amount; the structural formula of polyacrylonitrile is shown in formula (I), wherein R 1 and R 2 Same as shown in formula (b), wherein x is 0, and the average value of n in the molecular chain of polyacrylonitrile is 20;

[0052] (2) Product a is washed 3 times with deionized water to obtain product b;

[0053] (3) Place the product b in an aqueous solution of hydrochloric acid with 1 times i...

Embodiment 2

[0057] A kind of preparation method of the polymkeric substance containing diaminotriazine, the steps are as follows:

[0058] (1) After mixing polyacrylonitrile, dicyandiamide (structural formula as shown in formula (II)), a mixture of methanol and ethanol (volume ratio 1:1) and magnesium chloride, first react at 62°C for 2 hours, and then React at 82°C for 3 hours, and finally react at 105°C for 2 hours, and obtain product a after cooling down, wherein the mass ratio of polyacrylonitrile, dicyandiamide and methanol to ethanol (volume ratio 1:1) is 1:0.2: 10. In parts by weight, the addition of magnesium chloride is 2% of the addition of polyacrylonitrile; the structural formula of polyacrylonitrile is the same as that of Example 1, and the average value of n in the molecular chain of polyacrylonitrile is 35;

[0059] (2) Product a is washed 4 times with deionized water to obtain product b;

[0060] (3) Place the product b in an aqueous solution of hydrochloric acid whose ma...

Embodiment 3

[0064] A kind of preparation method of the polymkeric substance containing diaminotriazine, the steps are as follows:

[0065] (1) After mixing polyacrylonitrile, dicyandiamide (structural formula as shown in formula (II)), ionic liquid containing imidazolium salt ions, and aluminum trichloride, first react at 65°C for 3 hours, and then at 85°C React for 3 hours, and finally react at 106°C for 3 hours, and obtain product a after cooling down, wherein the mass ratio of polyacrylonitrile, dicyandiamide and ionic liquid containing imidazolium salt ions is 1:0.4:30, in parts by weight , the addition of aluminum chloride is 5% of the addition of polyacrylonitrile; The structural formula of polyacrylonitrile is identical with embodiment 1, and the average value of n in the molecular chain of polyacrylonitrile is 50;

[0066] (2) Product a is washed 5 times with deionized water to obtain product b;

[0067] (3) The product b is placed in an aqueous solution of hydrochloric acid whos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com