Anti-ultraviolet nano cobalt zinc oxide water-based ink and preparation method

A water-based ink and anti-ultraviolet technology, which is applied in the direction of nanotechnology, ink, and nanotechnology for materials and surface science, can solve the problem of poor anti-ultraviolet performance, poor thermal stability and chemical stability of water-based inks, which restrict the development of water-based inks It can achieve the effects of low production cost, enhanced shielding effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

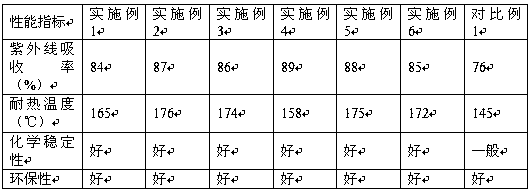

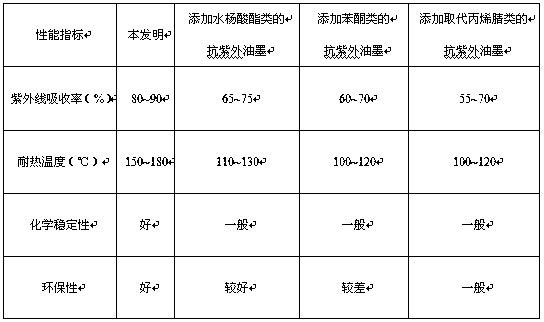

Examples

Embodiment 1

[0035] (1) The specific process of synthesis of nano-cobalt zinc oxide is:

[0036] First prepare the mixed solution of zinc nitrate and cobalt nitrate, then add cetyltrimethylammonium bromide and urea, and then heat under stirring. After the hydrothermal reaction is completed, carry out suction filtration, washing and drying to obtain nano Cobalt zinc oxide; in the mixed solution of zinc nitrate and cobalt nitrate, the mass concentration of zinc nitrate is 16%, and the mass concentration of cobalt nitrate is 11%; the heating temperature of hydrothermal reaction is 200 ℃, and the heating time is 4h; the washing process Using acetone, the number of times is 3 times; the drying process adopts infrared drying, and the moisture content after drying is 0.8%;

[0037] In the hydrothermal reaction system, in parts by weight: 78 parts of a mixed solution of zinc nitrate and cobalt nitrate, 4 parts of cetyltrimethylammonium bromide, and 18 parts of urea;

[0038] (2) The specific proc...

Embodiment 2

[0045] (1) The specific process of synthesis of nano-cobalt zinc oxide is:

[0046]First prepare the mixed solution of zinc nitrate and cobalt nitrate, then add cetyltrimethylammonium bromide and urea, and then heat under stirring. After the hydrothermal reaction is completed, carry out suction filtration, washing and drying to obtain nano Cobalt zinc oxide; in the mixed solution of zinc nitrate and cobalt nitrate, the mass concentration of zinc nitrate is 15%, and the mass concentration of cobalt nitrate is 8%; the heating temperature of hydrothermal reaction is 180 ℃, and the heating time is 4.5h; washing The process uses ether, and the number of times is 2; the drying process uses microwave drying, and the moisture content after drying is 0.6%;

[0047] In the hydrothermal reaction system, in parts by weight: 82 parts of a mixed solution of zinc nitrate and cobalt nitrate, 3 parts of cetyltrimethylammonium bromide, and 15 parts of urea;

[0048] (2) The specific process of...

Embodiment 3

[0055] (1) The specific process of synthesis of nano-cobalt zinc oxide is:

[0056] First prepare the mixed solution of zinc nitrate and cobalt nitrate, then add cetyltrimethylammonium bromide and urea, and then heat under stirring. After the hydrothermal reaction is completed, carry out suction filtration, washing and drying to obtain nano Cobalt zinc oxide; in the mixed solution of zinc nitrate and cobalt nitrate, the mass concentration of zinc nitrate is 18%, and the mass concentration of cobalt nitrate is 15%; the heating temperature of hydrothermal reaction is 210 ℃, and the heating time is 3h; the washing process Using acetone, the number of times is 4 times; the drying process adopts infrared drying, and the moisture content after drying is 0.7%;

[0057] In the hydrothermal reaction system, in parts by weight: 75 parts of a mixed solution of zinc nitrate and cobalt nitrate, 5 parts of cetyltrimethylammonium bromide, and 20 parts of urea;

[0058] (2) The specific proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com