Conductive plugging slurry and preparation method and application thereof

A technology of conductive paste and conductive plug, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc. Short, poor flexibility and other problems, to achieve the effect of good stability, stable conductivity, stable dispersion system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

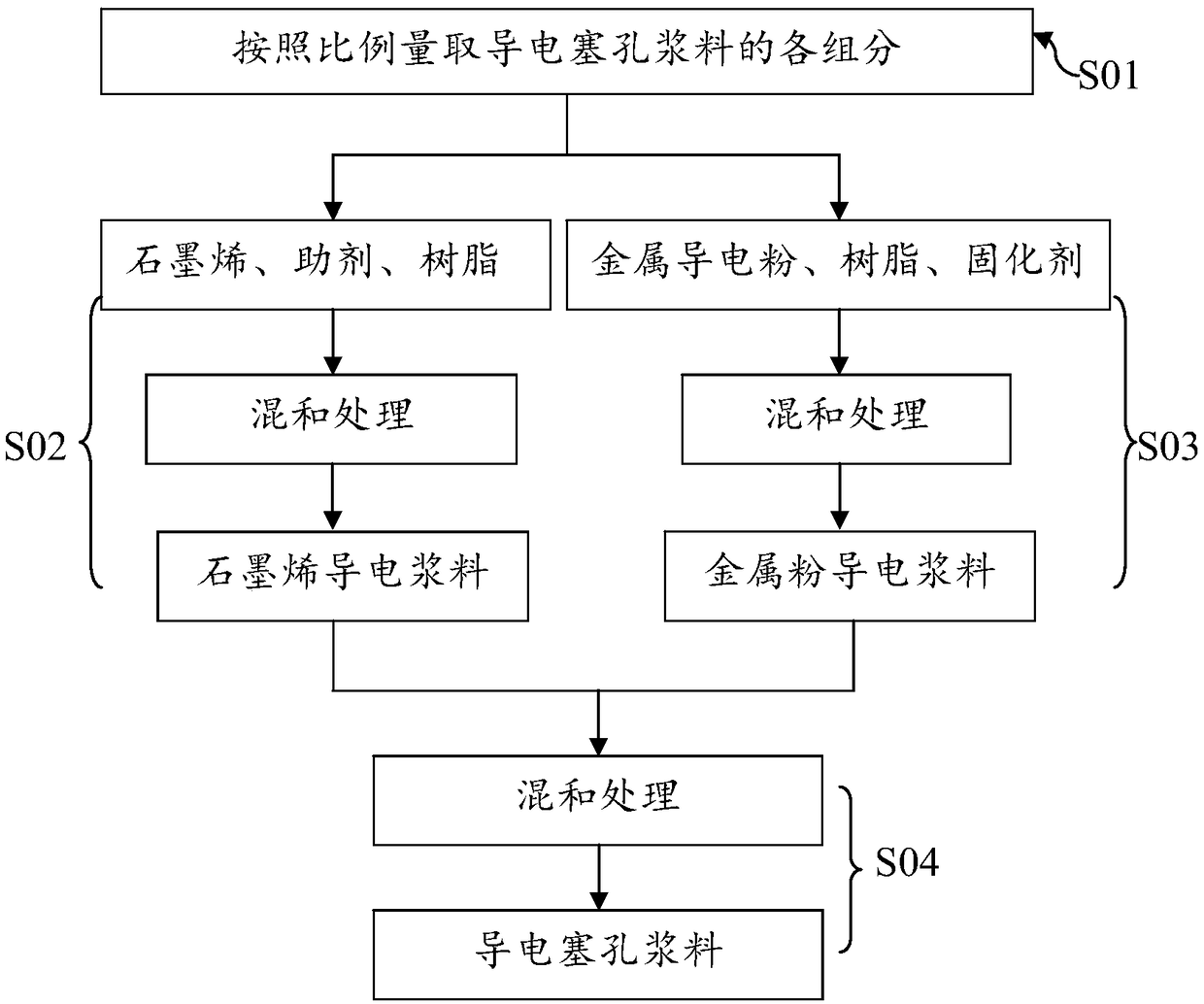

[0033]On the basis of the above-mentioned conductive plugging paste, the embodiment of the present invention also provides a preparation method of the above-mentioned conductive plugging paste. The process flow of the preparation method of the conductive plug hole slurry is as follows: figure 2 As shown, it includes the following steps:

[0034] Step S01. Measure the components of the conductive plug hole slurry according to the proportion: measure each component according to the components contained in the conductive plug hole slurry and the content of the components described above;

[0035] Step S02. Prepare graphene conductive paste: mix measured graphene, additives and a part of resin components to form graphene conductive paste;

[0036] Step S03. Prepare metal powder conductive paste: mix the measured metal conductive powder, another part of resin and curing agent to form metal powder conductive paste;

[0037] Step S04. Mixing the graphene conductive paste and the m...

Embodiment 1

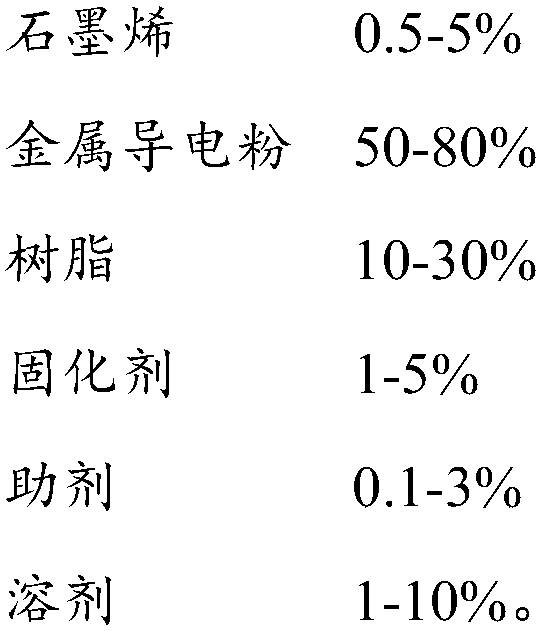

[0044] This embodiment provides a conductive plug hole paste. The conductive plug hole slurry includes the following mass percentage components:

[0045] Bisphenol A type epoxy resin (China Taiwan Nanya NPEL-128) 6%, bisphenol F type epoxy resin (China Taiwan Nanya NPEL-170) 13%, curing agent (Japan Ajinomoto PN-40, imidazoles) 1%, graphene (the sixth element SE1231) 3%, silver-coated copper powder (SPC-313 of Japan Co., Ltd.) 70%, wetting and dispersing agent (Deqian 903) 1%, diethylene glycol butyl ether (Dow )6%.

[0046] Its preparation method comprises the following steps:

[0047] S11. Stir and mix the graphene, bisphenol F epoxy resin, and wetting and dispersing agent, and then enter the sand mill for grinding and dispersing until the fineness is less than 10 μm, which is the graphene conductive paste;

[0048] S12. Stir and mix silver-coated copper powder, bisphenol A epoxy resin, and latent curing agent, and perform stirring and defoaming treatment in a revolution ...

Embodiment 2

[0051] This embodiment provides a conductive plug hole paste. The conductive plug hole slurry includes the following mass percentage components:

[0052] Novolac epoxy resin (China Taiwan Changchun PNE177) 6%, bisphenol F type epoxy resin (China Taiwan South Asia NPEL-170) 13%, curing agent (OMICURE DDA, dicyandiamide) 1%, graphene (sixth Element SE1231) 3%, silver-coated copper powder (Japan Co., Ltd. SPC-313) 70%, wetting and dispersing agent (Deqian 903) 1%, diethylene glycol butyl ether (Dow) 6%.

[0053] Its preparation method comprises the following steps:

[0054] S11. Stir and mix the graphene, bisphenol F epoxy resin, and wetting and dispersing agent, and then enter the sand mill for grinding and dispersing until the fineness is less than 10 μm, which is the graphene conductive paste;

[0055] S12. Stir and mix silver-coated copper powder, phenolic epoxy resin, and latent curing agent, and perform stirring and defoaming treatment in a revolution and rotation mixer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com