Method for synthesizing nanometer bismuth oxycarbonate through room-temperature solid phase chemical reaction

A bismuth oxycarbonate, chemical reaction technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve difficulties in realizing large-scale industrial production, product particle agglomeration, and increase preparation costs problem, to achieve the effect of easy industrial production, simple process and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 0.01 mole of sodium bismuthate dihydrate and 0.01 mole of oxalic acid dihydrate according to a molar ratio of 1:1 and add them into a 50 mL zirconia ball mill jar equipped with 50 zirconia balls with a diameter of 6 mm and 8 zirconia balls with a diameter of 10 mm. The QM-3SP04 planetary high-energy ball mill was continuously ball-milled at 480 rpm for 1.5 hours, the product was washed with distilled water, centrifuged and vacuum-dried at 60° C. and 0.1 Mpa vacuum for 2 hours to obtain the target product.

Embodiment 2

[0021] Weigh 0.01 mole of sodium bismuthate dihydrate and 0.01 mole of oxalic acid dihydrate according to a molar ratio of 1:1 and add them into a 50 mL zirconia ball mill jar equipped with 50 zirconia balls with a diameter of 6 mm and 8 zirconia balls with a diameter of 10 mm. The QM-3SP04 planetary high-energy ball mill was continuously ball-milled at 480 rpm for 2 hours, the product was washed with distilled water, centrifuged and vacuum-dried at 60° C. and 0.1 Mpa vacuum for 2 hours to obtain the target product.

Embodiment 3

[0023] Weigh 0.01 mole of sodium bismuthate dihydrate and 0.01 mole of oxalic acid dihydrate according to a molar ratio of 1:1 and add them into a 50 mL zirconia ball mill jar equipped with 50 zirconia balls with a diameter of 6 mm and 8 zirconia balls with a diameter of 10 mm. The QM-3SP04 planetary high-energy ball mill was continuously ground at 480rpm for 10 hours, the product was washed with distilled water, centrifuged and vacuum-dried at 60°C and 0.1Mpa vacuum for 2 hours to obtain the target product.

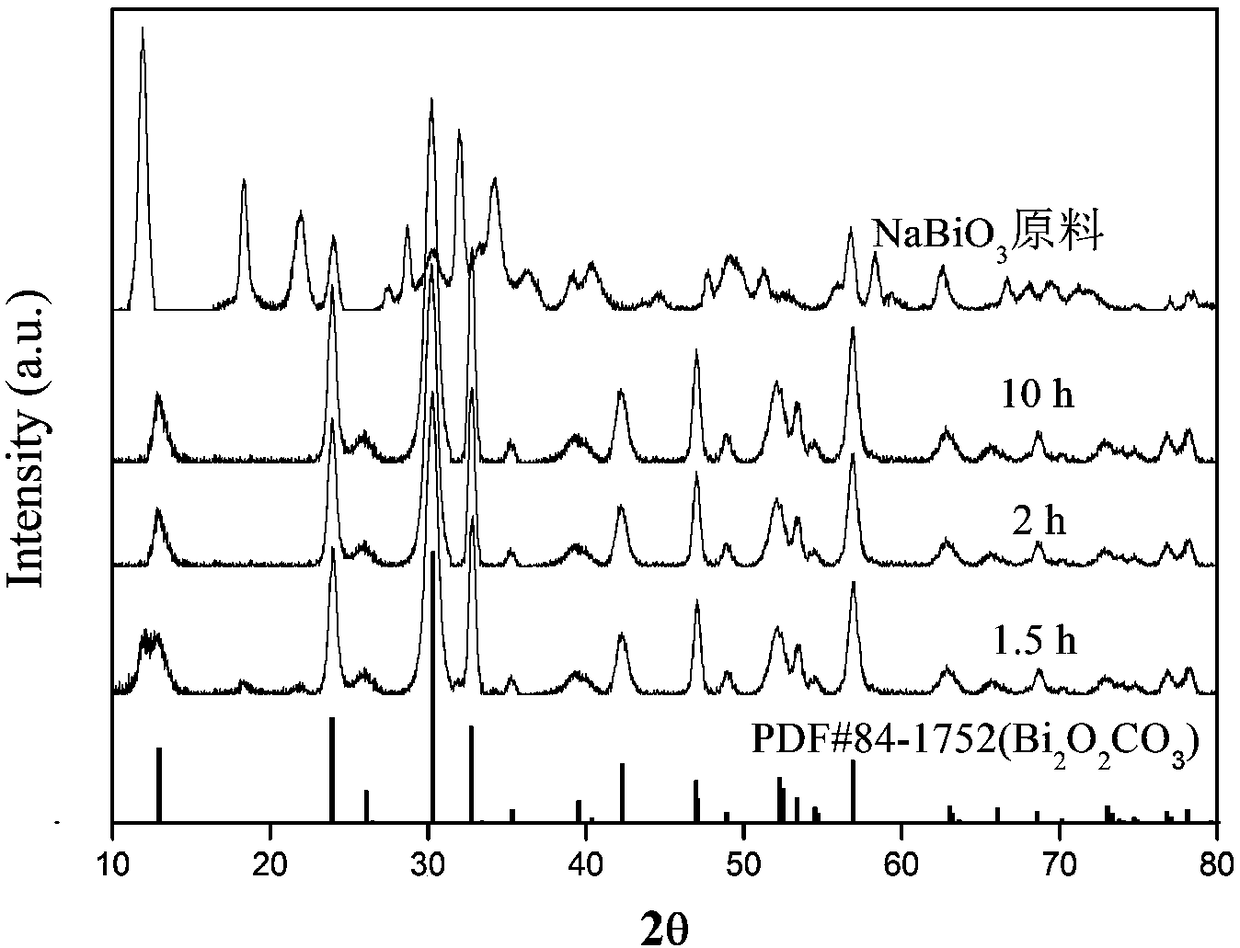

[0024] The X-ray diffraction analysis (XRD analysis) of above-mentioned embodiment gained target product: the target product that embodiment 1, embodiment 2 and embodiment 3 make and raw material sodium bismuthate dihydrate are carried out XRD analysis respectively, and the results are shown in figure 1 , it can be seen that in the XRD pattern of the product obtained in Example 1, Bi 2 o 2 CO 3 In addition to the characteristic diffraction peaks, there is also a small ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com