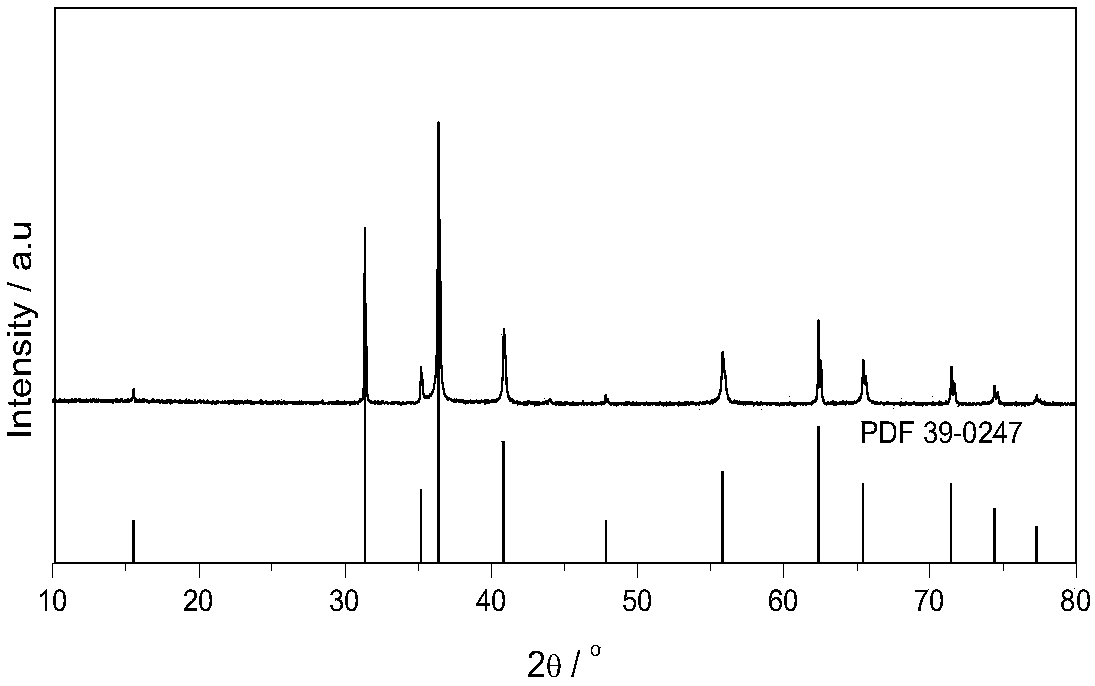

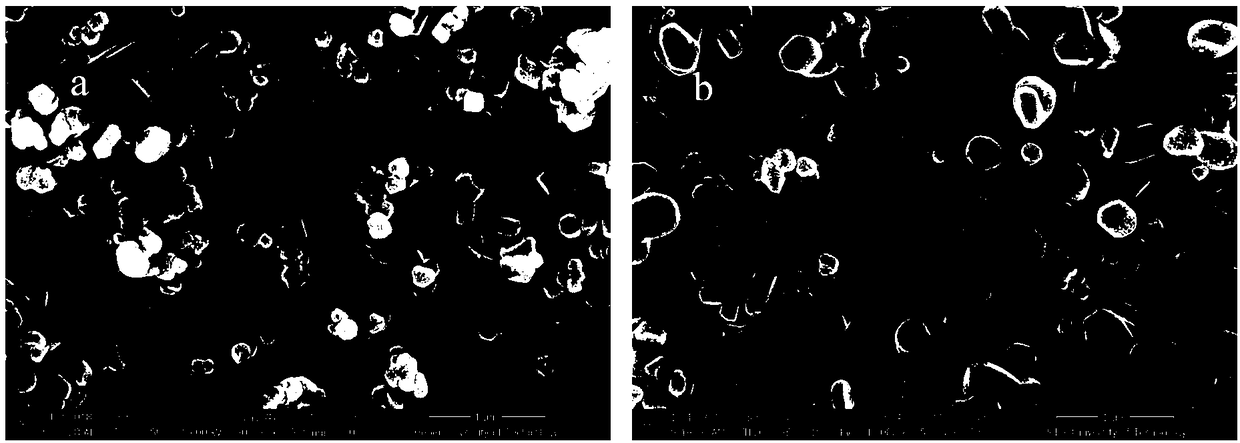

Sol-gel preparation methd of CuCrO2 powder

A sol-gel and powder technology, applied in the field of photocatalysis, can solve the problems of unfavorable coordination of citric acid with chromium and copper ions, unfavorable dispersion of copper and chromium atoms, insufficient particle size distribution, etc., and achieves good hydrogen production activity from water splitting, Small particles and good crystal integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 4g copper nitrate trihydrate (0.016556mol) and 6.624g chromium nitrate nonahydrate (0.016556mol), put it into a tall beaker, add deionized water to make copper nitrate+chromium nitrate total mass concentration is 5% aqueous solution;

[0025] (2) Weigh citric acid according to the molar ratio of citric acid and (copper nitrate + chromium nitrate) at 1.7:1, add it to the solution obtained in the previous step, and add ethylene glycol which is equimolar to citric acid, and then stir 0.5h, forming a colorless and transparent solution;

[0026] (3) Transfer the solution obtained in (2) to a water bath at 85°C, and stir continuously for 5.5 hours until a viscous liquid is formed;

[0027] (4) The viscous liquid obtained in (3) was removed from the water bath and lowered to room temperature, then 8 mL of 10 mol / L ammonia water was added thereto, and stirred at room temperature for 0.5 h;

[0028] Wherein: the mol ratio that adds ammonia in step (4) and adds nitrat...

Embodiment 2

[0036] Take the same method as described in embodiment 1 step (1)~(7) to prepare CuCrO 2 powder, the difference is that the mol ratio of citric acid to (copper nitrate+chromium nitrate) is 1.2:1, and all the other preparation conditions are the same as in Example 1. The resulting CuCrO 2 The WO prepared by powder and embodiment 1 step (8) 3 Carry out composite, prepare composite catalyst, and test the photocatalytic hydrogen production activity of composite catalyst, the proportioning, preparation method and activity test method of composite catalyst are as described in embodiment 1 step (9), record the generation amount of hydrogen to be 1.6mL .

Embodiment 3

[0038] Take the same method as described in embodiment 1 step (1)~(7) to prepare CuCrO 2 powder, the difference is that the ratio of ethylene glycol to citric acid is 0.8:1, and the rest of the preparation conditions are the same as in Example 1. The resulting CuCrO 2 The WO prepared by powder and embodiment 1 step (8) 3 Carry out composite, prepare composite catalyst, and test the photocatalytic hydrogen production activity of composite catalyst, the proportioning, preparation method and activity test method of composite catalyst are as described in embodiment 1 step (9), record the generation amount of hydrogen to be 1.9mL .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com