A kind of ultra-thin ag nanosheet with clean surface and preparation method thereof

A nanosheet and ultra-thin technology, applied in the field of ultra-thin Ag nanosheets and their preparation, can solve the problems affecting the electrochemical sensing limit and sensitivity, and the surface advantages of Ag nanosheets cannot be fully utilized, and achieve good cycle performance and stability. Performance, high detection limit, high detection sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Another aspect of the present invention provides a kind of preparation method of the ultra-thin Ag nano sheet of clean surface, comprises the steps:

[0022] (1) Add an alkaline solution to a certain concentration of copper salt solution, and then add a reducing agent to make Cu 2+ reduced to Cu + , to obtain cuprous oxide;

[0023] (2) The cuprous oxide that step (1) obtains is put into ethylene glycol solution, adds alkaline solution and reducing agent successively, with Cu + reduced to Cu 0 , to obtain a hollow Cu shell;

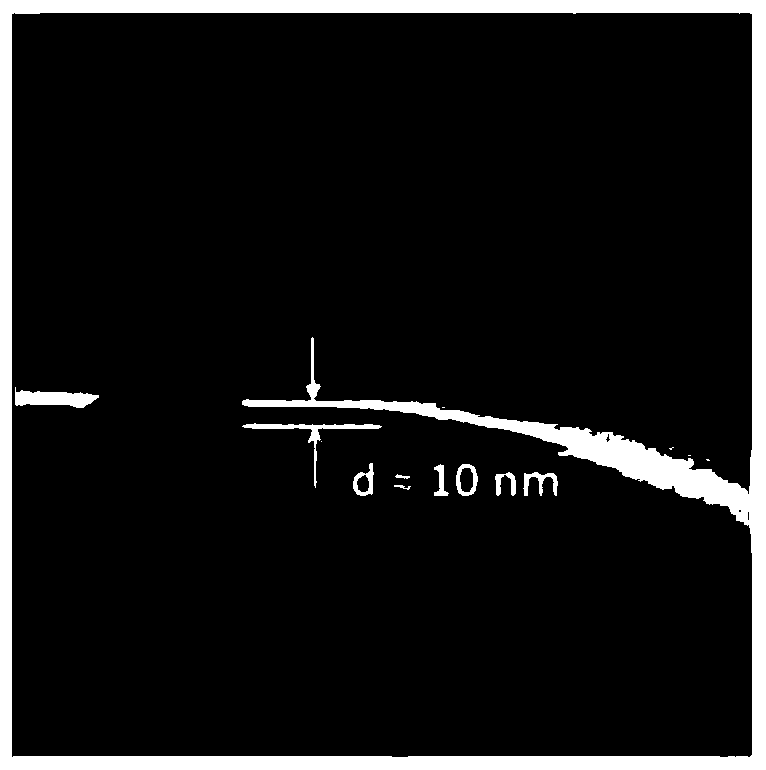

[0024] (3) Put the hollow Cu shell obtained in step (2) into a certain amount of silver nitrate solution, stir under normal temperature and pressure, and the Ag + replaced by Ag 0 , collect and dry the gray powder obtained to obtain the ultrathin Ag nanosheets with a thickness of 10-20nm.

[0025] Preferably, the copper salt is copper chloride, copper sulfate or copper acetate.

[0026] Preferably, the alkaline solution is sodium hydroxide. ...

Embodiment 1

[0035] (1) Add 30ml of sodium hydroxide solution (3M) to 50ml of copper chloride solution (0.3M), then add 0.6g of glucose powder, and keep the entire reaction temperature at 70°C. 2+ reduced to Cu + , reacted for 30 minutes to obtain a 26-hedral cuprous oxide.

[0036] (2) Disperse the cuprous oxide of 26-hedron in 180ml ethylene glycol solution, add 60ml of sodium hydroxide solution (5M), then add 60ml of glucose solution (1.1M), the whole reaction temperature remains at 60°C, and Cu + reduced to Cu 0 , and reacted for 120 minutes to obtain a hollow Cu shell.

[0037] (3) Put the hollow Cu shell into a certain amount of silver nitrate solution, wherein the molar ratio of Cu and Ag is 5:7, stir at 550rpm at room temperature at 23°C, and mix Ag + replaced by Ag 0 , centrifuge at 7000rpm for 2 minutes to collect and dry the obtained gray powder to obtain monodisperse ultra-thin nano-Ag sheets with a thickness of about 10 nm.

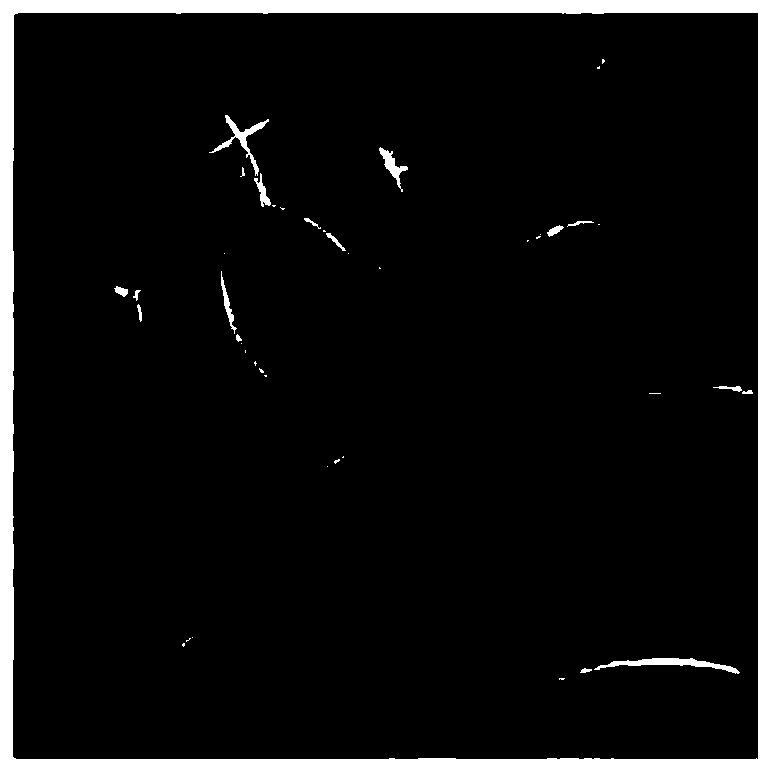

[0038] The scanning electron microscope pictu...

Embodiment 2

[0041] (1) Add 30ml of sodium hydroxide solution (3M) to 50ml of copper chloride solution (0.3M), then add 0.5g of glucose powder, and keep the entire reaction temperature at 70°C. 2+ reduced to Cu + , reacted for 30 minutes to obtain a 26-hedral cuprous oxide.

[0042] (2) Disperse the cuprous oxide of 26-hedron in 180ml ethylene glycol solution, add 60ml of sodium hydroxide solution (5M), then add 60ml of glucose solution (1.1M), the whole reaction temperature remains at 60°C, and Cu + reduced to Cu 0 , and reacted for 120 minutes to obtain a hollow Cu shell.

[0043] (3) Put the hollow Cu shell into a certain amount of silver nitrate solution, wherein the molar ratio of Cu and Ag is 5:6, and stir at 550rpm at room temperature at 23°C, and the Ag + replaced by Ag 0, centrifuge at 7000rpm for 2 minutes to collect and dry the obtained gray powder to obtain monodisperse ultrathin nano-Ag sheets with a thickness of about 15nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com