Preparation method of cation modified polyacrylamide as well as sewage treatment method

A technology of polyacrylamide and treatment method, which is applied in the direction of water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of unsatisfactory environmental assessment standards, unsatisfactory use effect, and residual water quality There are many impurities and other problems, and the composition and use process of the water purifying agent are simplified and the effect of remarkable purification effect is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Disclosed is a preparation method of cationic modified polyacrylamide; it comprises the following steps:

[0025] (1) Add 50ml-100ml of deionized water, 15g-25g of acrylamide with a concentration of 0.2-0.5g / ml, and 5g-10g of dimethyldiallyl ammonium chloride with a concentration of 0.1-0.3g / ml into the container , urea 0.05-0.2g, edetate disodium 0.05-0.2g;

[0026] (2) Pass nitrogen into the container (three-necked flask) to remove the oxygen in the container;

[0027] (3) Stir for 0.5h;

[0028] (4) Dissolve 0.01-0.002 g of ammonium persulfate and 0.01-0.002 g of a mixture of sodium borohydride and azobisisobutylamidine hydrochloride with a total mass of 0.0125% in 2 to 3 ml of deionized water to form a solution. (3) In the stirred solution;

[0029] (5) Heat up to 45-55°C, and stop the reaction when the reaction solution turns into a transparent colloid;

[0030] (6) Reduce the temperature and dry the colloid at 70°C to 90°C to constant weight and then pulverize...

Embodiment 1

[0045] Preparation of 30% monomer concentration cationic modified polyacrylamide (CPAM):

[0046] 1. In a three-necked flask equipped with a stirrer, reflux condenser and conduit, add 21g of acrylamide, 9g of dimethyl diallyl ammonium chloride, 0.1g of urea, EDTA-2Na salt (ethylenediaminetetraacetic acid di Sodium) 0.1g, deionized water 70mL;

[0047] 2. Continue to stir for 30 minutes and pass nitrogen;

[0048] 3. Slowly add the composite initiator dropwise: 0.0053g of ammonium persulfate, 0.0037g of sodium borohydride, 0.0125g of azobisisobutylamidine hydrochloride and 2-3mL of deionized water;

[0049] 4. React in a water bath at 50°C for 2-3 hours until the solution turns into a transparent colloid;

[0050] 5. Take out the reactants and dry them in a constant temperature oven at 75°C to constant weight, then pulverize them to obtain cationic modified polyacrylamide (CPAM).

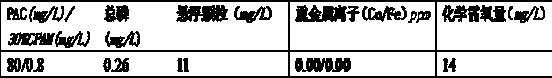

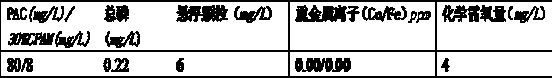

[0051] Using the cationic modified polyacrylamide (CPAM) water purification steps of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com