Two-dimensional nano-filler synergistic flame retardant as well as preparation method and application thereof

A synergistic flame retardant and two-dimensional nanotechnology, applied in the field of polymer flame retardants, can solve the problems of polymer mechanics, aging and other performance degradation, poor compatibility with polymer matrix, uneven dispersion, etc., and achieve raw materials The ratio is scientific and reasonable, the dispersion is good, and the preparation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The composition of the two-dimensional nano-filler synergistic flame retardant described in this example is 100 parts by mass of ammonium polyphosphate (intumescent flame retardant, Shandong Changsheng, CS FR APP 232), graphene oxide (1-5 layers, Pioneer Nanometer, XF224) 10 mass parts, tannic acid (hydrolyzed tannin, Chinese medicine) 20 mass parts, ferric chloride (Chinese medicine) 10 mass parts, this synergistic flame retardant adopts following steps to prepare:

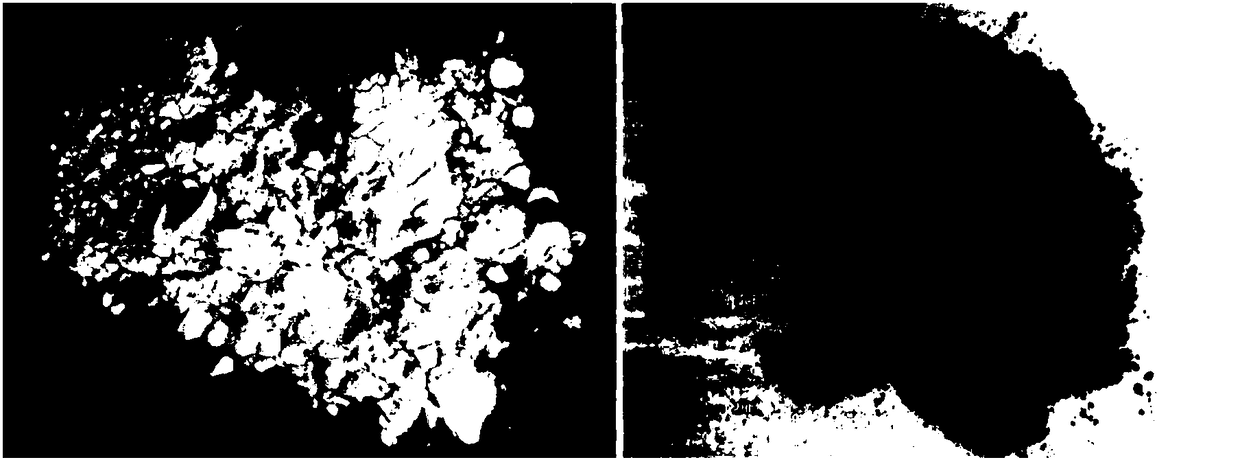

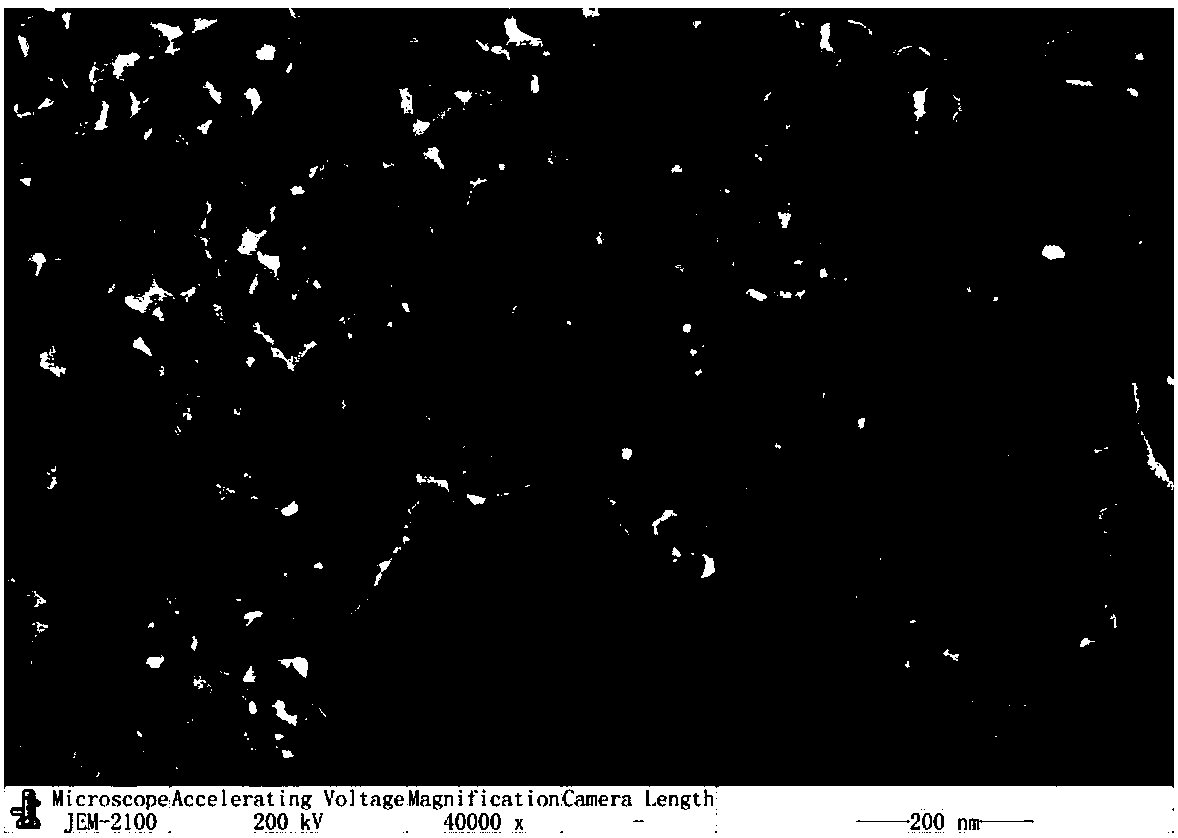

[0025] (1) Disperse 100 parts by mass of ammonium polyphosphate in an alkaline aqueous solution of pH=10, add 10 parts by mass of tannic acid and 2.5 parts by mass of ferric chloride, stir and react for 10 minutes, wash with water until neutral, and obtain coated ammonium polyphosphate, figure 1 For the color comparison of ammonium polyphosphate before and after coating, the color of ammonium polyphosphate after coating changes from white to dark brown, which visually proves that the coating reaction is su...

Embodiment 2

[0032] The composition of the two-dimensional nano-filler synergistic flame retardant described in this embodiment is 100 parts by mass of red phosphorus (inorganic flame retardant, Chuanlin Chemical Industry), 100 parts by mass of organoclay (1-10 layers, NANOCOR, I.31PS) 100 parts by mass of tea tannin (condensed tannin, Fengtai Biology), 50 parts by mass of cobalt sulfate (Aladdin), the synergistic flame retardant is prepared in the following steps:

[0033] (1) Disperse 100 parts by mass of red phosphorus in an alkaline aqueous solution of pH=8, add 50 parts by mass of tea tannin and 12.5 parts by mass of cobalt sulfate, stir and react for 30 minutes, wash with water until neutral, and obtain the coated red phosphorus;

[0034] (2) Disperse 100 parts by mass of organoclay in an aqueous solution of 50 parts by mass of tea tannins, add 12.5 parts by mass of cobalt sulfate, adjust the pH to 8, stir for 30 minutes, wash with water until neutral, and obtain the coated organic ...

Embodiment 3

[0040] The composition of the two-dimensional nano-filler synergistic flame retardant described in this example is 100 parts by mass of decabromodiphenyl ether (halogenated flame retardant, Zhengzhou Zhiyi), black phosphorus nanosheets (1-10 layers, Pioneer Nano, XF207) 2 mass parts, Quercus angustifolia tannin (complex polyphenols, Qingdao Tailian) 5 mass parts, zirconium chloride (Aladdin) 1 mass part, the synergistic flame retardant is prepared by the following steps:

[0041] (1) Disperse 100 parts by mass of decabromodiphenyl ether in an alkaline aqueous solution of pH = 12, add 2.5 parts by mass of Quercus angustifolia tannin and 0.25 parts by mass of zirconium chloride, stir and react for 1 min, wash with water until medium properties, to obtain coated decabromodiphenyl ether;

[0042] (2) Disperse 2 parts by mass of black phosphorus nanosheets in an aqueous solution of 2.5 parts by mass of Quercus angustifolia tannins, add 0.25 parts by mass of zirconium chloride, adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com