Anionic flexible graphene electrothermal composite, anionic flexible graphene electrothermal composite film as well as preparation methods and applications

A flexible graphite and composite material technology, applied in the field of materials, can solve the problems of low far-infrared conversion efficiency, complicated preparation method and process, low flexibility of electrothermal composite film, etc., and achieves the effects of high infrared heat conversion efficiency, simple operation and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

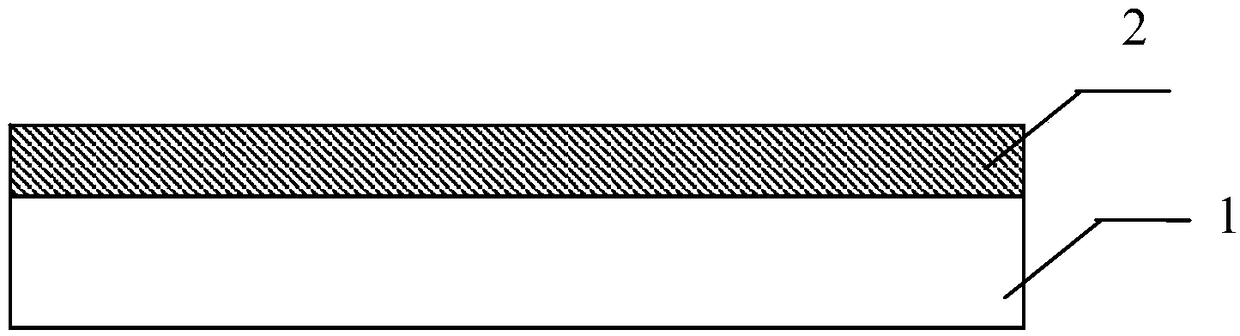

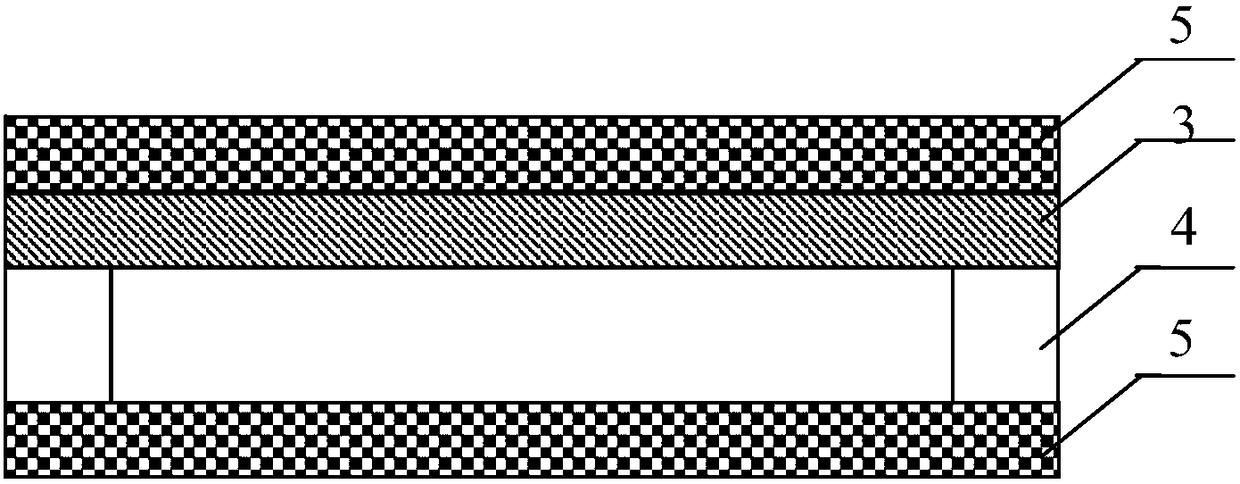

[0079] The present invention also provides the preparation method of the above-mentioned negative ion flexible graphene electrothermal composite material, comprising:

[0080] Disperse and grind the mixture of graphene, negative ion powder, dispersant and part of the flexible resin in the formulated amount to obtain a pre-dispersed slurry, mix and disperse the pre-dispersed slurry with the remaining flexible resin, and pass through a 80-120 mesh sieve to obtain Negative ion flexible graphene electrothermal composite material.

[0081] The preparation method of the negative ion flexible graphene electrothermal composite material provided by the present invention is simple to operate, and through specific operation steps such as dispersing and grinding the raw materials, the raw materials can be made to cooperate with each other to obtain a flexible, stable heating, safe to use and infrared Negative ion flexible graphene electrothermal composite material with high heat conversio...

Embodiment 1

[0111] This embodiment provides a kind of negative ion flexible graphene electrothermal composite material, comprising:

[0112] 3 parts of graphene with a sheet diameter of 10 μm, 1.5 parts of tourmaline powder with a particle size of 0.8 μm, 50 parts of water-based polyurethane resin and 0.5 parts of polyvinylpyrrolidone.

Embodiment 2

[0114] This embodiment provides a kind of negative ion flexible graphene electrothermal composite material, comprising:

[0115] 1.5 parts of graphene with a sheet diameter of 10 μm, 0.5 parts of tourmaline powder with a particle size of 0.8 μm, 50 parts of water-based polyurethane resin and 0.25 parts of polyvinylpyrrolidone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com