A kind of water-based wood paint and preparation method thereof

A water-based wood lacquer and modification technology, applied in the field of wood lacquer, can solve the problems of slow drying speed and unsatisfactory film-forming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

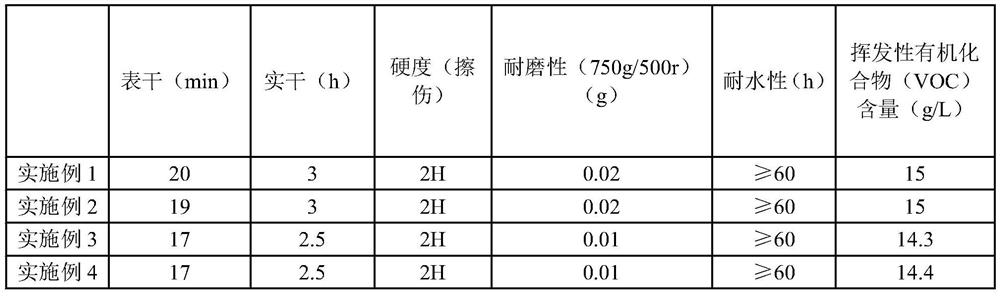

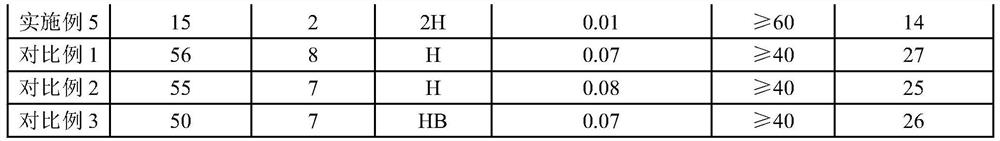

Examples

Embodiment 1

[0036] A water-based wood lacquer is made of the following components by weight: 40 parts of alkyd resin jointly modified by sucrose polyester and acrylic acid, 20 parts of aliphatic modified polyurethane dispersion, 12 parts of vinyl acetate resin, emulsified 2 parts of agent, 2 parts of dispersant, 1 part of defoamer, 1 part of leveling agent, 2 parts of accelerator, 1 part of initiator, 20 parts of deionized water.

[0037] Among them, the alkyd resin jointly modified by sucrose polyester and acrylic acid has an oil degree of 40% and an acid value of 40 mgKOH / g.

[0038] The aliphatic modified polyurethane dispersion is made from coconut oil, isophorone diisocyanate, polyether diol and aminopropyl triethoxysilane through prepolymer-ionomer mixing method.

[0039] The emulsifier is sorbitan monopalmitate; the dispersant is alkylphenol polyoxyethylene ether; the defoamer is silicone defoamer; the leveling agent is fluorocarbon modified acrylic leveling agent.

[0040] The ac...

Embodiment 2

[0053] A water-based wood lacquer is made of the following components by weight: 50 parts of alkyd resin jointly modified by sucrose polyester and acrylic acid, 30 parts of aliphatic modified polyurethane dispersion, 18 parts of vinyl acetate resin, emulsified 3 parts of agent, 3 parts of dispersant, 2 parts of defoamer, 2 parts of leveling agent, 3 parts of accelerator, 2 parts of initiator, 30 parts of deionized water.

[0054] Wherein, the alkyd resin jointly modified by sucrose polyester and acrylic acid has an oil degree of 50% and an acid value of 70 mgKOH / g.

[0055] The aliphatic modified polyurethane dispersion is made from coconut oil, isophorone diisocyanate, polyether diol and aminopropyl triethoxysilane through prepolymer-ionomer mixing method.

[0056] The emulsifier is sorbitan monopalmitate; the dispersant is octylphenol polyoxyethylene ether; the defoamer is silicone defoamer; the leveling agent is fluorocarbon modified acrylate leveling agent.

[0057] The a...

Embodiment 3

[0070] A water-based wood lacquer is made of the following components by weight: 40 parts of alkyd resin jointly modified by sucrose polyester and acrylic acid, 30 parts of aliphatic modified polyurethane dispersion, 12 parts of vinyl acetate resin, emulsified 3 parts of agent, 2 parts of dispersant, 2 parts of defoamer, 1 part of leveling agent, 3 parts of accelerator, 1 part of initiator, 30 parts of deionized water.

[0071] Wherein, the alkyd resin jointly modified by sucrose polyester and acrylic acid has an oil degree of 40% and an acid value of 70 mgKOH / g.

[0072] The aliphatic modified polyurethane dispersion is made from coconut oil, isophorone diisocyanate, polyether diol and aminopropyl triethoxysilane through prepolymer-ionomer mixing method.

[0073] The emulsifier is sorbitan monopalmitate; the dispersant is polyacrylamide; the defoamer is silicone defoamer; the leveling agent is fluorocarbon modified acrylate leveling agent.

[0074] The accelerator is a mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com