A water-washable letterpress photosensitive resin composition and its products

A resin composition and photosensitive resin technology, applied in printing plates, optics, opto-mechanical equipment, etc., can solve the problems of increasing process complexity, affecting printing quality, insufficient polymerization, etc., and achieving high dot reducibility and photosensitive wavelength range. Wide, fully cured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0044] S1 (2-mercaptoisobutyric acid modified hydrophilic polyamide resin)

[0045] Add 70 parts of 1,4-bis(γ-aminopropyl)piperazine adipate, 20 parts of ε-caprolactam, and 10 parts of deionized water into a stainless steel autoclave. After nitrogen replacement, seal it and slowly heat to 240°C, react for 2 hours, from internal pressure to 10kg / cm 2 , until the water vapor can no longer maintain the pressure, slowly return to normal pressure, and then react under normal pressure for 1h. After cooling down, add 5 parts of 2-mercaptoisobutyric acid to the reaction mixture, replace it with nitrogen, seal it, then slowly raise the temperature to 220°C, and react at this temperature for 2 hours to obtain a mercapto-modified hydrophilic polyamide resin . Then lower the temperature and cool down, add 40 parts of nylon 66 salt to the reaction mixture, replace with nitrogen, seal and slowly raise the temperature to 240°C, and react for 1 hour to obtain a mercapto-modified polyamide r...

Embodiment 1

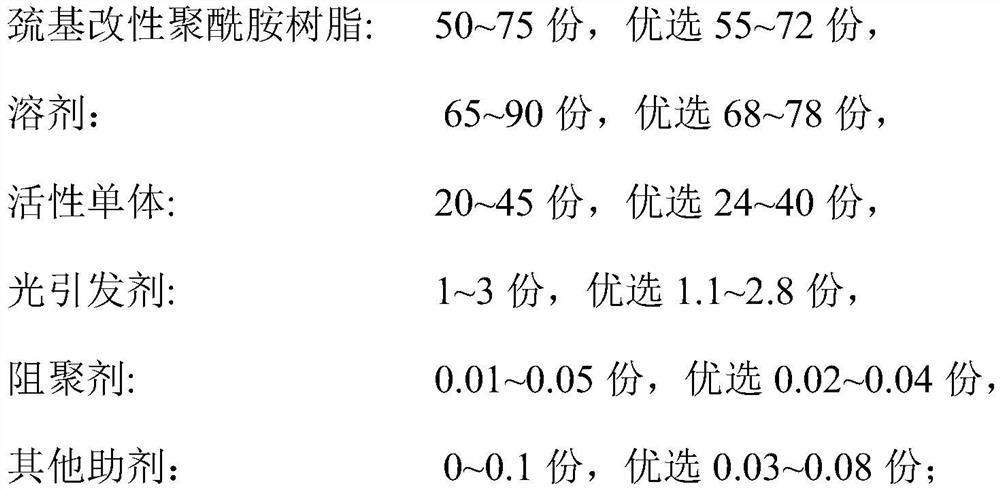

[0051] The above-mentioned synthetic mercapto-modified water-based polyamide resin is formulated into a photosensitive resin composition according to the following formula:

[0052]

[0053]

Embodiment 2

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com