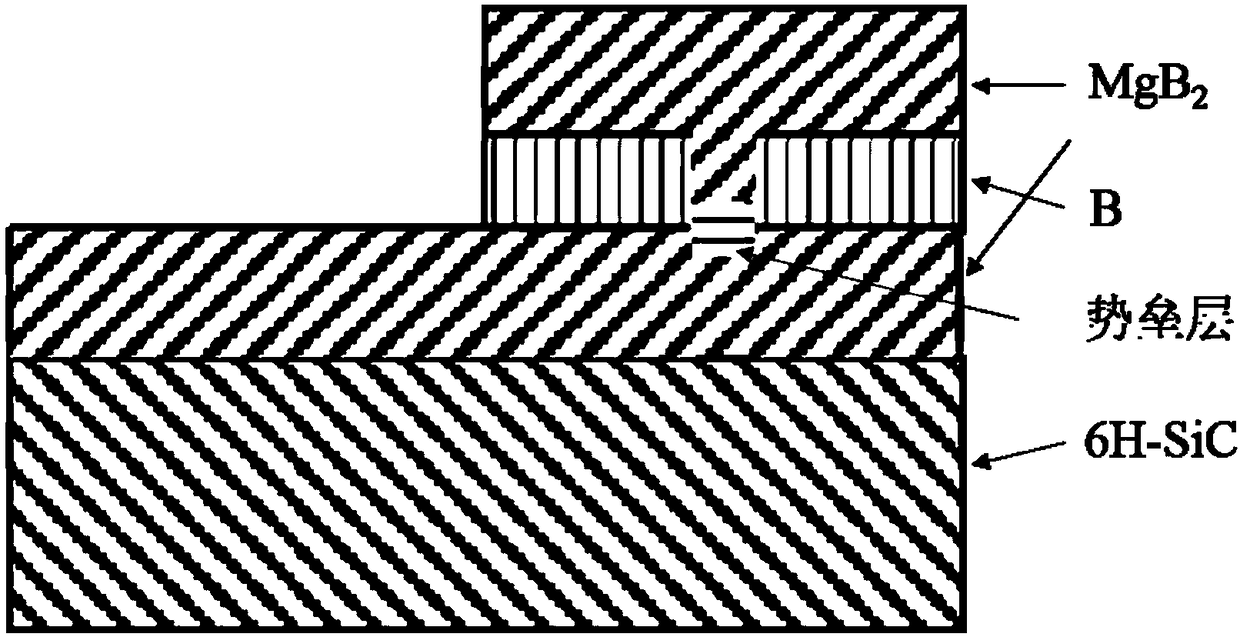

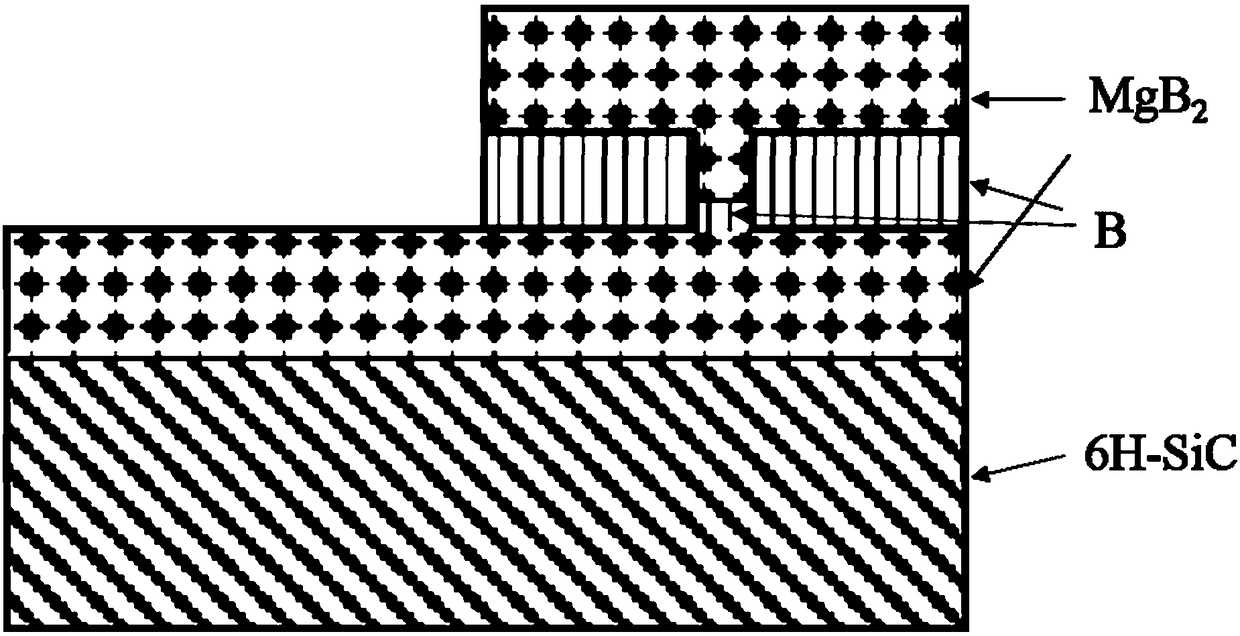

MgB2 Josephson junction and fabrication method thereof

A technology of magnesium diboride and boride, applied in the direction of devices including a node of different materials, manufacturing/processing of superconductor devices, superconducting devices, etc. Repeatability influence, complex preparation process and other issues, to achieve the effect of good repeatability, precise and controllable experimental parameters, and flexible preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

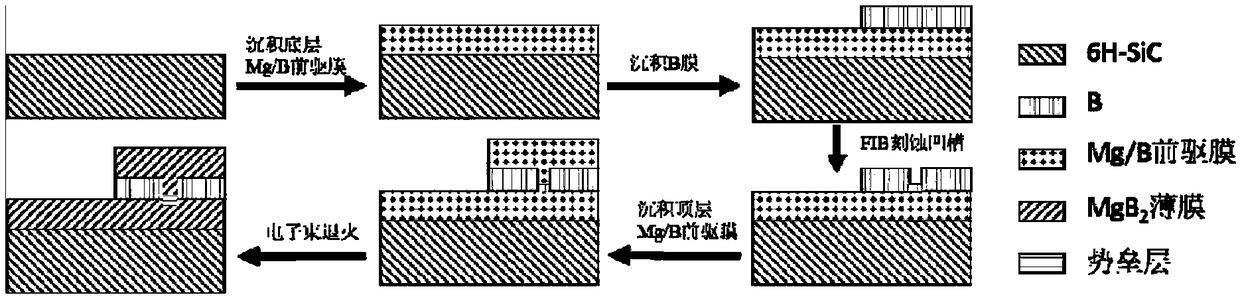

Embodiment 1

[0030] The preparation of the precursor film in this embodiment is completed in the ZZXS-500 electron beam coating machine, the focused ion beam etching equipment is FEI 820 DualBeam type focused ion beam / electron beam dual beam system (Focused Ion Beam, FIB), and the electron beam annealing is in It is carried out on a self-made EBW-3H electron beam welding machine, the substrate is 6H-SiC (0001), and the size is 3mm×5mm.

[0031] 1. Preparation of precursor film:

[0032] 1) Fix a 6H-SiC bare substrate with a size of 3mm×5mm on the sample workpiece table of the coating machine;

[0033] 2) closing the reaction chamber and evacuating the reaction chamber;

[0034] 3) Wait until the vacuum degree of the reaction chamber reaches 5×10 -5 After Pa, select the electron beam voltage of 7kV, the electron beam current of 50mA, and turn on the electron gun power supply;

[0035] 4) Deposit Mg film 15nm, deposit B film 10nm, alternately deposit 4 layers of magnesium film and 4 layer...

Embodiment 2

[0043] The preparation of the precursor film in this embodiment is completed in the ZZXS-500 electron beam coating machine, the focused ion beam etching equipment is FEI 820 DualBeam type focused ion beam / electron beam dual beam system (Focused Ion Beam, FIB), and the electron beam annealing is in It is carried out on a self-made EBW-3H electron beam welding machine, the substrate is 6H-SiC (0001), and the size is 3mm×5mm.

[0044] 1. Preparation of precursor film:

[0045] 1) Fix a 6H-SiC substrate with a size of 3mm×5mm on the sample workpiece table of the coating machine;

[0046] 2) closing the reaction chamber and evacuating the reaction chamber;

[0047] 3) Wait until the vacuum degree of the reaction chamber reaches 5×10 -5 After Pa, select the electron beam voltage of 7kV, the electron beam current of 80mA, and turn on the electron gun power supply;

[0048] 4) Deposit Mg film 15nm, deposit B film 10nm, alternately deposit 4 layers of magnesium film and 4 layers of ...

Embodiment 3

[0056] The preparation of the precursor film in this example is completed in the ZZXS-500 electron beam coating machine. The focused ion beam etching equipment is FEI820DualBeam focused ion beam / electron beam dual beam system (Focused Ion Beam, FIB). -3H type electron beam welding machine, the substrate is 6H-SiC (0001), and the size is 3mm×5mm.

[0057] 1. Preparation of precursor film:

[0058] 1) Fix a 6H-SiC bare substrate with a size of 3mm×5mm on the sample workpiece table of the coating machine;

[0059] 2) closing the reaction chamber and evacuating the reaction chamber;

[0060] 3) Wait until the vacuum degree of the reaction chamber reaches 5×10 -5 After Pa, select the electron beam voltage of 7kV, the electron beam current of 100mA, and turn on the electron gun power supply;

[0061] 4) Deposit Mg film 15nm, deposit B film 10nm, alternately deposit 4 layers of magnesium film and 4 layers of boron film according to this order, the thickness ratio of magnesium film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Superconducting transition temperature | aaaaa | aaaaa |

| Superconducting transition temperature | aaaaa | aaaaa |

| Superconducting transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com