Anode material, preparation method thereof, negative plate, and lithium ion battery

A technology of negative electrode material and negative electrode plate, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low energy density of batteries, low tap density of materials, not suitable for practical applications, etc., and achieve comprehensive electrochemical performance improvement. , high electrical conductivity, the effect of improving the rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The negative electrode material is introduced above, and the preparation method of the negative electrode material is described in detail below, and the specific steps are as follows:

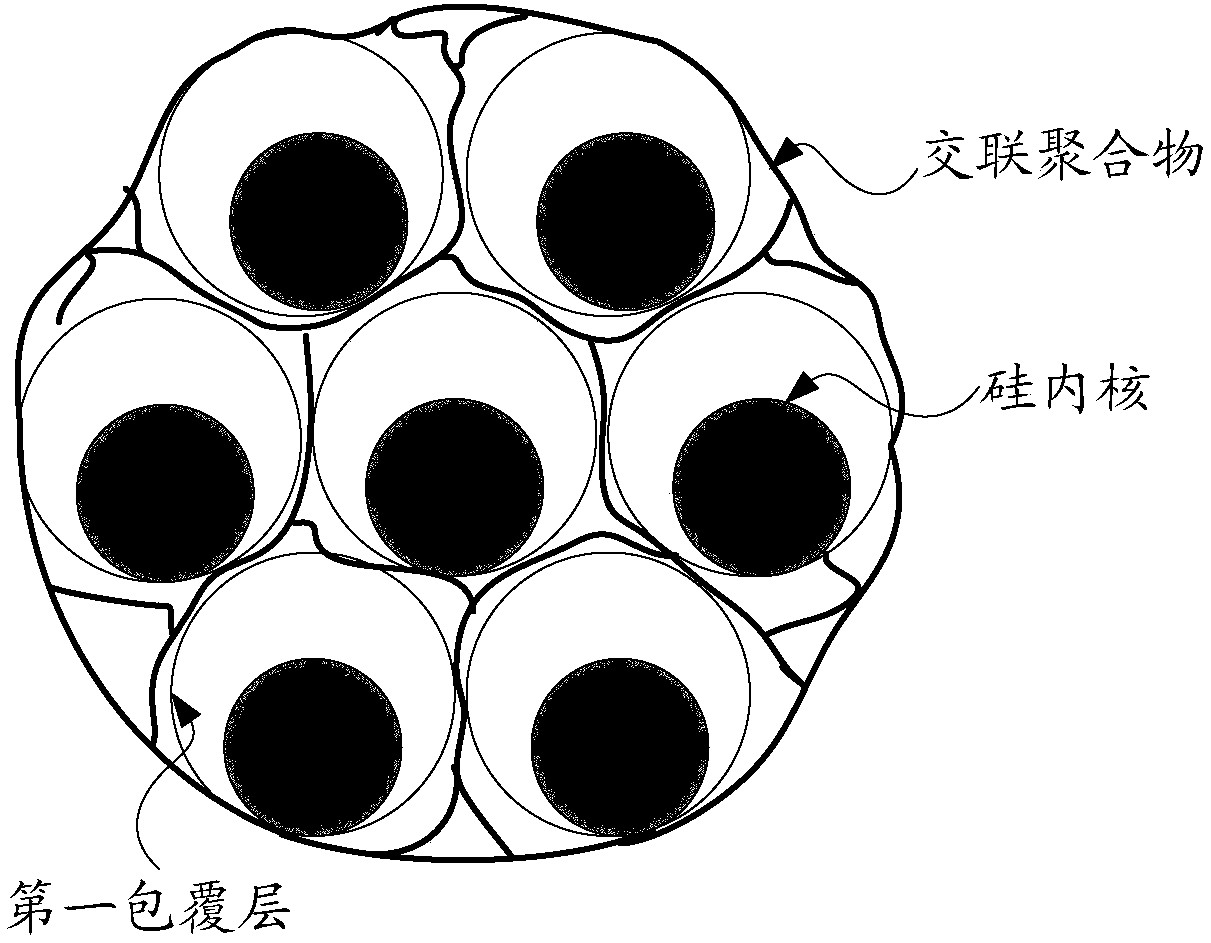

[0062] According to the technical problems solved by the embodiments of the present invention, the index of the negative electrode material can be divided into two parts, the first part is the process of preparing the first particle, and the second part is the process of preparing the second particle by cross-linking the polymer. It should be understood that the second part in the embodiment of the present invention can be implemented alone, that is, directly close-packing the existing nano-scale particles with the properties of the first particle; it can also be implemented in combination with the first part, that is, first preparing the first particle, and then The first particles are subjected to close packing. This embodiment of the present invention does not limit it. The preparati...

Embodiment 1

[0077] Example 1. Silicon@zinc oxide (Si@ZnO) hollow shell core nanoparticles are used as the first particle, diethylene glycol diacrylate phthalate is used as the cross-linked polymer, and carbon nanotubes are used as the conductive additive. The negative electrode material, the specific steps are as follows:

[0078] 201. Prepare a third particle, wherein the third particle is a silicon@amorphous carbon (Si@C) core-shell nanoparticle.

[0079] Specifically, using silicon particles with a particle size of less than 100 nanometers (nm) as the silicon core, 4 g of glucose and 100 mg of cetrimonium bromide were dissolved in 40 mL of deionized water to form a clear solution; then 1 g of the silicon core material was ultrasonically dispersed in the solution and then transferred together to a 50mL hydrothermal reactor at 180°C for 8 hours (h); the solution was cooled to room temperature to form an amorphous carbon-coated black solid product, which was collected by centrifugation an...

Embodiment 2

[0087] Embodiment 2, using silicon@titanium dioxide (Si@TiO 2 ) Hollow-shell core nanoparticles are the first particle, the mixed toluene solution of sodium carboxymethyl cellulose is the cross-linked polymer, and the graphene nanosheet dispersion is the negative electrode material formed by the conductive additive, and the specific steps are as follows:

[0088] 301. Prepare a third particle, wherein the third particle is a silicon@amorphous carbon (Si@C) core-shell nanoparticle.

[0089] Specifically, using silicon particles with a particle size of less than 100 nanometers (nm) as the silicon core, 4 g of glucose and 100 mg of cetrimonium bromide were dissolved in 40 mL of deionized water to form a clear solution, and then 1 g of nano-silicon powder was uniformly dispersed in the solution, and transferred together to a 50mL hydrothermal reactor for 8 hours at 180°C; after the solution was cooled to room temperature, the coated black solid product was collected by centrifugat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com