System device and application for desorbing hydrogen sulfide in gas phase

A system device, hydrogen sulfide technology, applied in combustible gas purification, sulfur preparation/purification, combustible gas purification/transformation, etc. Process mass transfer efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

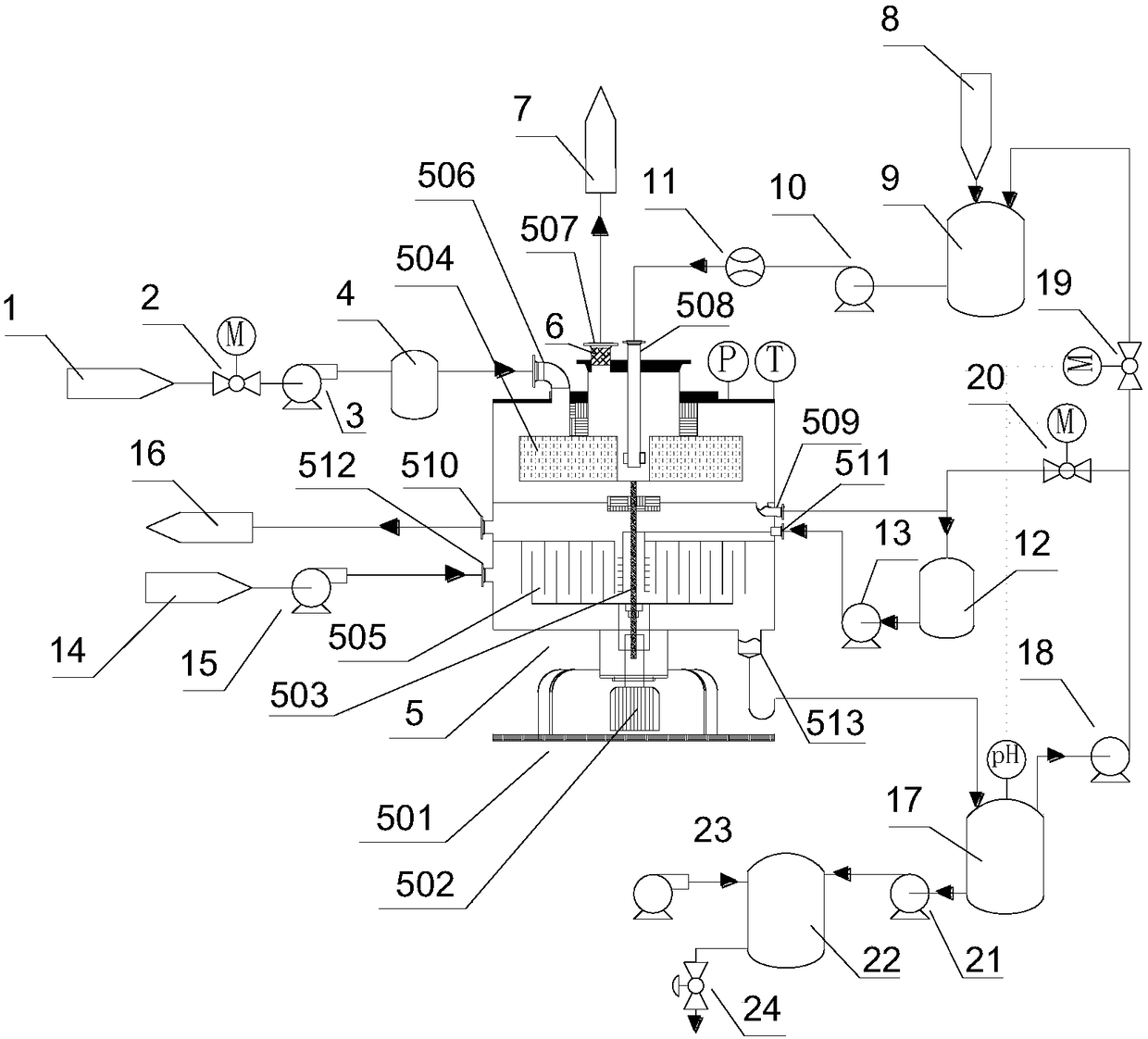

[0045] Such as figure 1 As shown, the present invention proposes a system device for removing hydrogen sulfide in the gas phase, comprising a feed gas inlet 1, a first valve 2, a first blower 3, a separator 4, a two-stage rotating packed bed absorption-regeneration device 5, Demister 6, first-stage exhaust gas discharge port 7, fresh absorbent addition port 8, lean liquid tank 9, first centrifugal pump 10, flow meter 11, rich liquid tank 12, second centrifugal pump 13, air inlet 14, The second blower 15, the second-stage tail gas discharge port 16, the sedimentation separation system 17, the third centrifugal pump 18, the second valve 19, the third valve 20, the fourth centrifugal pump 21, the sulfur recovery system 22, the third blower 23, The fourth valve 24 .

[0046] The two-stage rotating packed bed absorption-regeneration device 5 is installed vertically, including a base 501, a motor 502, a coupling 503, a two-stage rotating packed bed, a first-stage gas inlet 506, a f...

Embodiment 2

[0064] Use the device and technology of embodiment 1 to carry out oilfield associated gas removal hydrogen sulfide:

[0065] Capacity: 20000Nm 3 , the pressure is 12MPa, the hydrogen sulfide content is 200ppm, the gas temperature is 60°C, the complex iron in the lean liquid tank is used as the absorbing liquid, and the amount of absorbing liquid is 150m 3 / h. Using this process, the hydrogen sulfide content of the associated gas at the outlet is 2ppm, and it will run for one year during the regeneration process to clean up the stator-rotor blockage.

Embodiment 3

[0067] Use the device and technique of embodiment 1 to carry out the removal of hydrogen sulfide from natural gas:

[0068] Capacity: 60000Nm 3 , the pressure is 1MPa, the hydrogen sulfide content is 6000ppm, the gas temperature is 6℃, complex iron is selected as the absorption liquid in the lean liquid tank, and the absorption liquid consumption is 100m 3 / h. Using this process, the hydrogen sulfide content of the associated gas at the outlet is 3ppm, and it will run for 1 year during the regeneration process to clean up the stator-rotor blockage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com