Starch octenylsuccinate, preparation method, and application thereof

A technology of octenyl succinic acid and starch ester, which is applied in the field of modified starch production, can solve the problems of emulsion thickening and difficult pouring, and achieve high solid dispersion, good emulsification, and improved hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

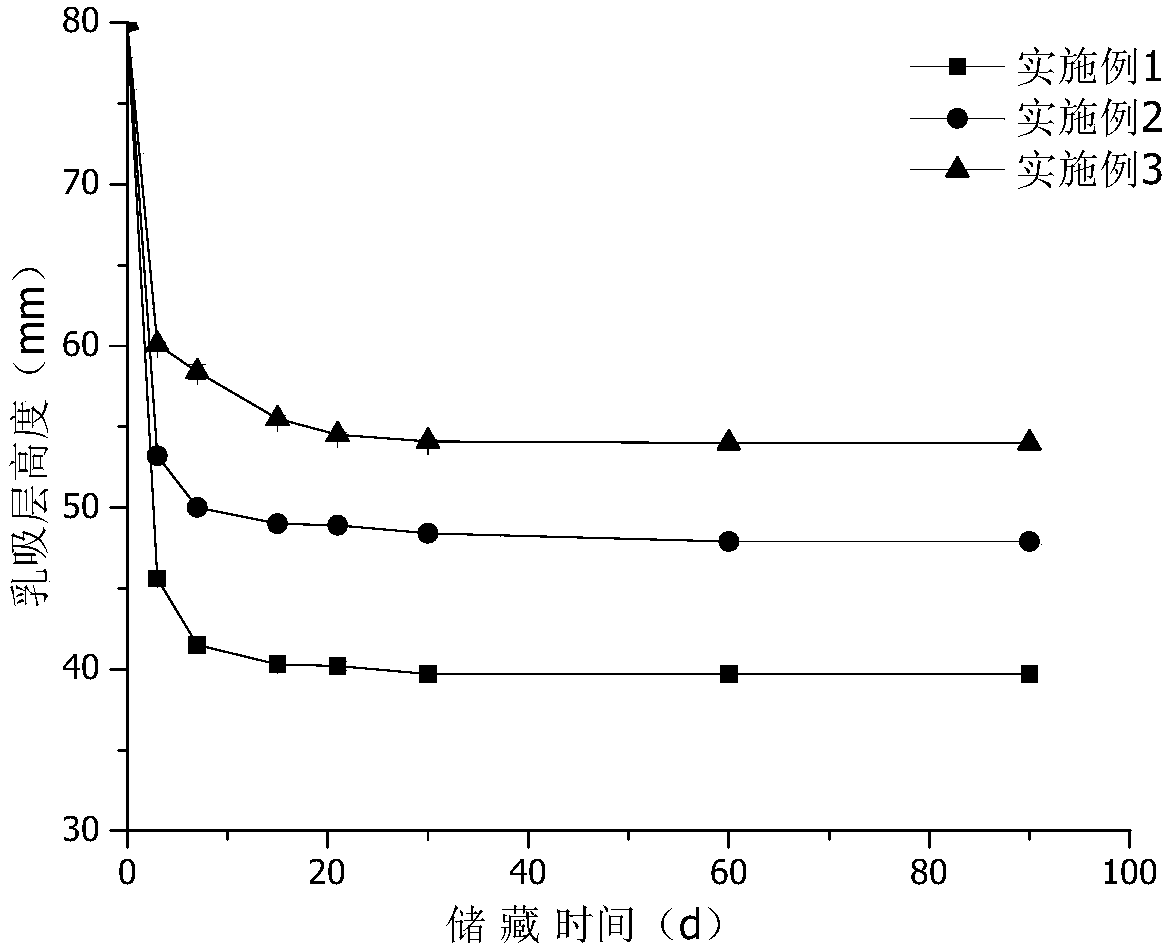

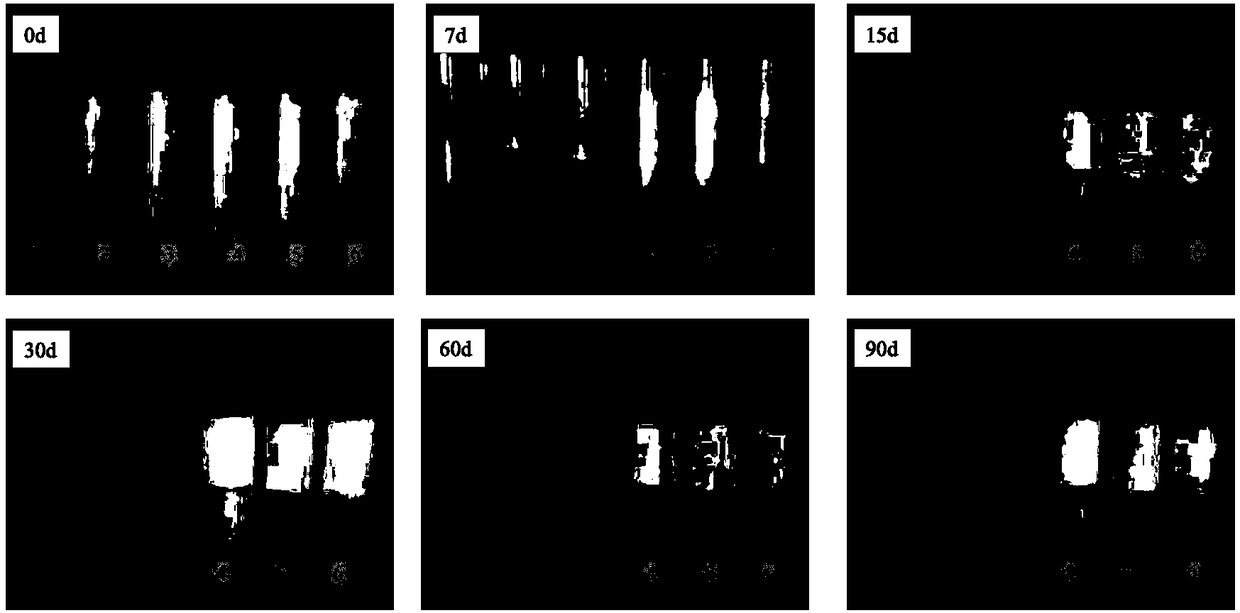

Embodiment 1

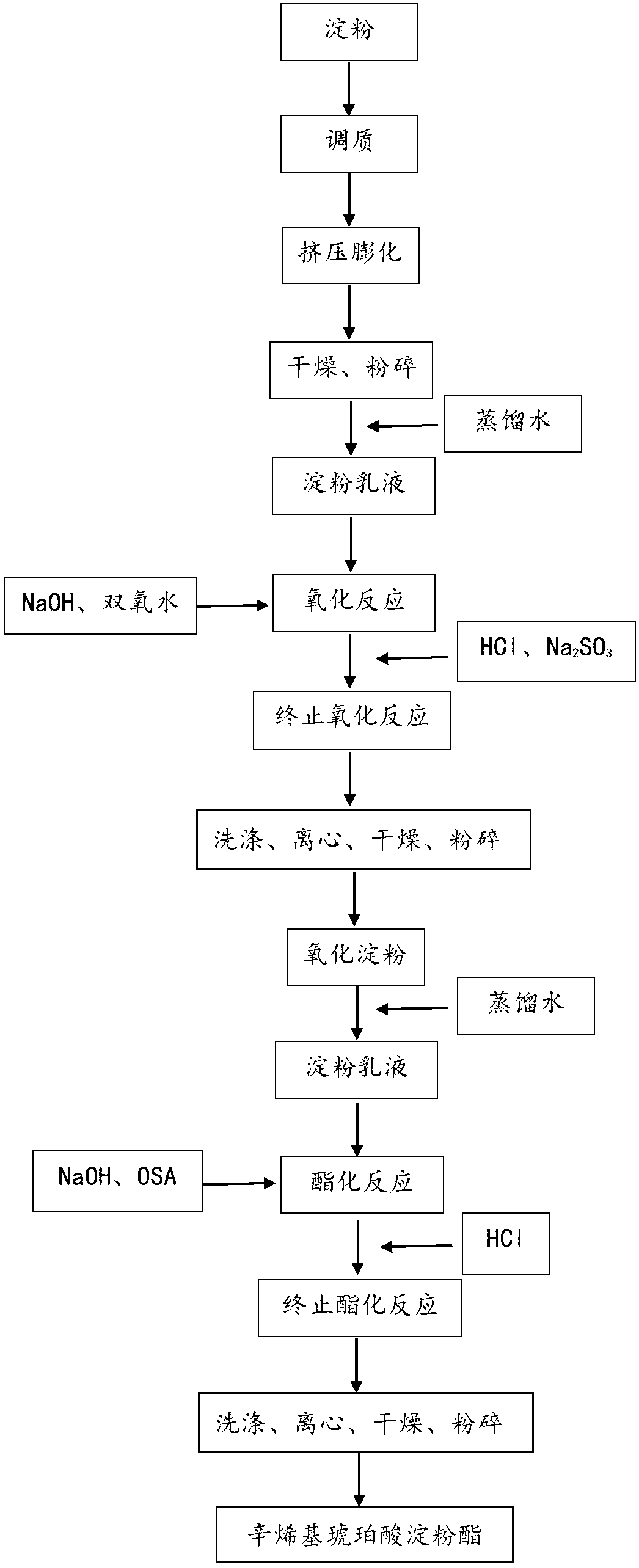

[0028] Such as figure 1 Shown, a kind of preparation method of octenyl starch succinate:

[0029] 1) With quinoa starch as raw material, in the extruder, the moisture content of the material is 40%, the feeding speed is 10kg / h, the temperature at the discharge port of the extruder is 100°C, the screw speed is 300rpm, the discharge port The diameter of the circular die hole in the die head is 4.5 mm, and the starch is extruded and expanded for pretreatment.

[0030] 2) Prepare the activated starch obtained in step 1) into a 15% starch emulsion, adjust the pH to 9.5 with 3% NaOH solution, stir in a water bath and heat up to 50°C, mix the starch emulsion uniformly and stabilize it for a period of time, and slowly add a mass fraction of 30% (starch dry basis) hydrogen peroxide.

[0031] 3) After the solution described in step 2) reacted for 3 hours, add an appropriate amount of sodium sulfite solution to neutralize the remaining hydrogen peroxide until the end, add 3% HCl soluti...

Embodiment 2

[0035]1) With quinoa starch as raw material, in the extruder, the moisture content of the material is 40%, the feeding speed is 20kg / h, the temperature at the discharge port of the extruder is 150°C, the screw speed is 350rpm, the discharge port The diameter of the circular die hole in the die head is 4.5 mm, and the starch is extruded and expanded for pretreatment.

[0036] 2) Prepare the activated starch obtained in step 1) into a 15% starch emulsion, adjust the pH to 9.5 with 3% NaOH solution, stir in a water bath and heat up to 50°C, mix the starch emulsion evenly and stabilize it for a period of time, then slowly add a mass fraction of 30% (starch dry basis) hydrogen peroxide.

[0037] 3) After the solution described in step 2) reacted for 3 hours, add an appropriate amount of sodium sulfite solution to neutralize the remaining hydrogen peroxide until the end, add 3% HCl solution to adjust the pH to 6.5, centrifuge to discard the supernatant, and then wash with 70% ethano...

Embodiment 3

[0041] 1) With quinoa starch as raw material, in the extruder, the moisture content of the material is 30%, the feeding speed is 10kg / h, the temperature at the discharge port of the extruder is 125°C, the screw speed is 350rpm, the discharge port The diameter of the circular die hole in the die head is 4.5 mm, and the starch is extruded and activated for pretreatment.

[0042] 2) Prepare the activated starch obtained in step 1) into a 15% starch emulsion, adjust the pH to 9.5 with 3% NaOH solution, stir in a water bath and heat up to 50°C, mix the starch emulsion uniformly and stabilize it for a period of time, and slowly add a mass fraction of 30% (starch dry basis) hydrogen peroxide.

[0043] 3) After the solution described in step 2) reacted for 3 hours, add an appropriate amount of sodium sulfite solution to neutralize the remaining hydrogen peroxide until the end, add 3% HCl solution to adjust the pH to 6.5, centrifuge to discard the supernatant, and then wash with 70% et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com