QCM (Quartz Crystal Microbalance) gas sensor modified by polyaniline nanowires as well as preparation method and application of QCM gas sensor

A gas sensor, nanowire technology, applied in nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve the problems of difficult to control the thickness of the film, weak bonding between the film and the surface of the electrode, and poor consistency of the prepared components. Achieve the effect of low cost, improved gas sensing performance and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of the gas sensor:

[0034] Proceed as follows:

[0035] 1) Dissolve 2-10 mL of aniline monomer in 60-90 ml of water and stir to form a uniform aniline solution. The water is ultra-pure water with a resistivity of 18.2 MΩ·cm;

[0036] 2) Take 1-5 mL of perchloric acid, dissolve it in 15-30 mL of water, stir to form a uniform perchloric acid solution, and the water is ultrapure water with a resistivity of 18.2 MΩ·cm;

[0037] 3) Mix equal volumes of the solutions obtained in steps 1) and 2), and stir evenly to obtain a 30-50 mL mixed solution;

[0038] 4) Add 0.005 ~ 0.05g hydroxyethyl cellulose to the mixed solution obtained in step 3);

[0039] 5) Immerse the quartz wafer in a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide with a volume ratio of 1:3, take it out after two minutes, rinse it, and dry it in nitrogen to obtain the treated quartz crystal micro balance;

[0040] 6) Connect one pin of the quartz crystal mic...

Embodiment 1

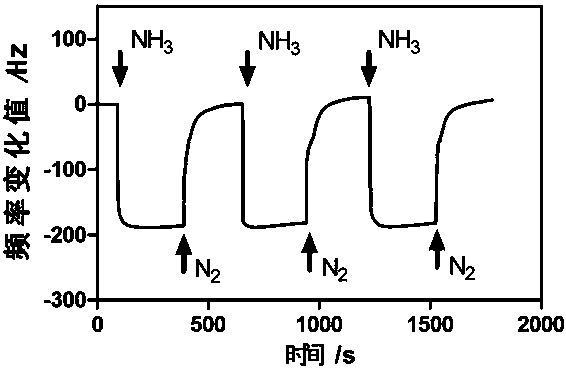

[0049] Dissolve 2 mL of aniline in 60 mL of water and stir to form an aqueous solution of aniline. Dissolve 1 mL of perchloric acid in 15 mL of water to obtain an aqueous solution of perchloric acid. The above solutions were mixed in equal volumes and stirred to obtain 15 mL of mixed solution. Take 0.005g of hydroxyethyl cellulose and add it into the above mixed solution, stir to dissolve it. Remove the metal shell of the quartz crystal microbalance, immerse the quartz wafer in a mixed solution of concentrated sulfuric acid with a mass fraction of 98% and hydrogen peroxide with a mass fraction of 30% at a volume ratio of 1:3, take it out after two minutes, rinse it with water, and Blow dry under nitrogen. Connect one pin of the QCM to the electrochemical workstation as the working electrode, and the other pin is suspended in the air. The silver / silver chloride electrode is used as the reference electrode, and the platinum electrode is used as the auxiliary electrode to form ...

Embodiment 2

[0051] Dissolve 6 mL of aniline in 80 mL of water and stir to form an aqueous solution of aniline. Dissolve 3 mL of perchloric acid in 20 mL of water to obtain an aqueous solution of perchloric acid. The above solutions were mixed in equal volumes and stirred to obtain 20 mL of mixed solution. Take 0.02g of hydroxyethyl cellulose and add it to the above mixed solution, stir to dissolve it. Remove the metal shell of the quartz crystal microbalance, immerse the quartz wafer in a mixed solution of concentrated sulfuric acid with a mass fraction of 98% and hydrogen peroxide with a mass fraction of 30% at a volume ratio of 1:3, take it out after two minutes, rinse it with water, and Blow dry under nitrogen. Connect one pin of the QCM to the electrochemical workstation as the working electrode, and the other pin is suspended in the air. The silver / silver chloride electrode is used as the reference electrode, and the platinum electrode is used as the auxiliary electrode to form a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com