Self-doped fullerene immobilized palladium nan-electrocatalyst, preparation method and application

An electrocatalyst and self-doping technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of poor repeatability and complicated operation, and achieve the effect of simple operation, good repeatability and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

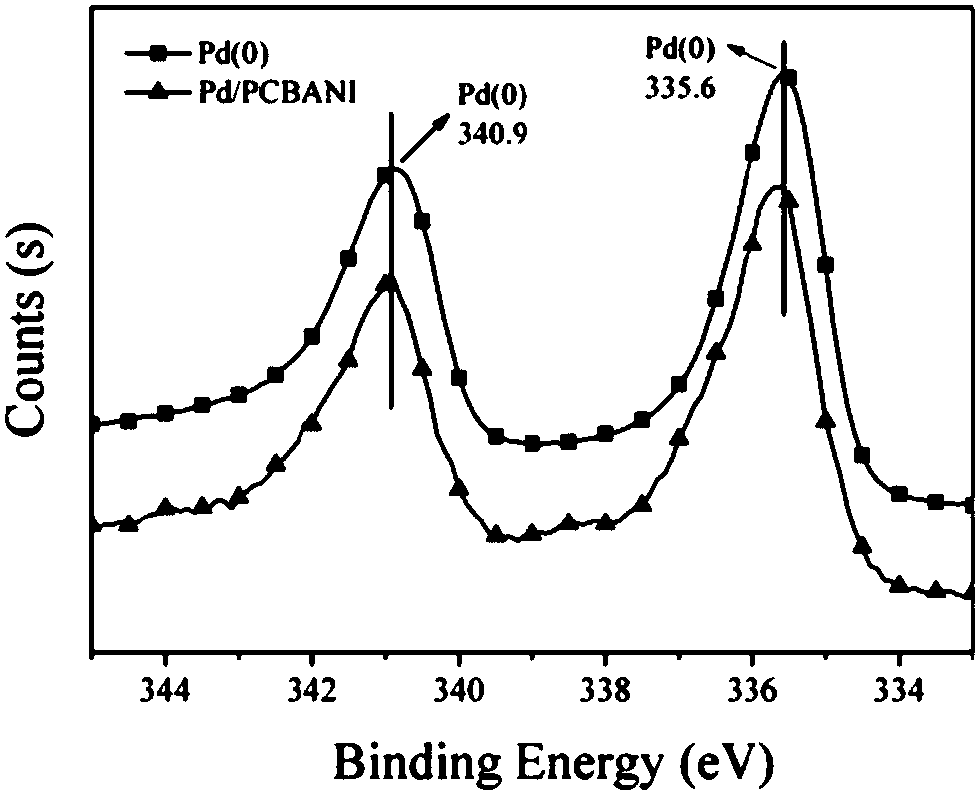

[0038] Mix 1.1 mg (1 μmol) PCBANI with 50 μL acetic acid and sonicate for 5 minutes, then add 1.95 mL methanol and sonicate for 15 minutes. Electrodes were ultrasonically cleaned with acetone, deionized water and ethanol for 5 min, respectively. Then the PCBANI dispersion was added dropwise on the electrode, and spin-coated at a speed of 300 rpm for 1.5 hours to obtain a PCBANI film. Subsequently, the electrode coated with PCBANI film was exposed to 1 mg / mL K 2 PdCl 4 Soak in aqueous solution for 30 minutes, soak in pure water for 10 minutes. It was then treated with hydrazine hydrate solution for 5 minutes and rinsed with deionized water. The Pd loading was determined by ICP-MS, and the obtained working electrode can be used for electrocatalytic activity test.

[0039] The electrocatalytic oxidation of ethanol was tested by cyclic voltammetry (CV) using a three-electrode system at room temperature. Pt electrode and Hg / HgO electrode were used as counter and reference elec...

Embodiment 2

[0043] Mix 2.2 mg (2 μmol) PCBANI with 50 μL acetic acid and sonicate for 5 minutes, then add 1.95 mL methanol and sonicate for 15 minutes. Then the PCBANI dispersion was added dropwise on the cleaned electrode, and spin-coated at a speed of 300 rpm for 1.5 hours to obtain a PCBANI film. Subsequently, the electrode coated with PCBANI film was exposed to 1 mg / mL K 2 PdCl 4 Soak in aqueous solution for 30 minutes, soak in pure water for 10 minutes. It was then treated with hydrazine hydrate solution for 5 minutes and rinsed with deionized water. The mass current density of the obtained working electrode for the electrocatalytic oxidation of ethanol is 969.9 A g -1 .

Embodiment 3

[0045] Mix 0.22 mg (0.1 μmol) PCBANI with 50 μL acetic acid and sonicate for 5 minutes, then add 1.95 mL methanol and sonicate for 15 minutes. Then the PCBANI dispersion was added dropwise on the cleaned electrode, and spin-coated at a speed of 300 rpm for 1.5 hours to obtain a PCBANI film. Subsequently, the electrode coated with PCBANI film was treated at 1mg / mLK 2 PdCl 4 Soak in aqueous solution for 30 minutes, soak in pure water for 10 minutes. It was then treated with hydrazine hydrate solution for 5 minutes and rinsed with deionized water. The obtained working electrode has a mass current density of 150 A g for the electrocatalytic oxidation of ethanol -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com