Butadiene styrene rubber and preparation method thereof

A technology of styrene-butadiene rubber and styrene, which is applied in the field of synthetic rubber, can solve the problems that the polymer microstructure cannot be adjusted, the polymer is not easy to couple, and no specific instructions are made, so as to achieve effective control, low production cost, The effect of fast polymerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Under the protection of high-purity nitrogen, add 2000g of cyclopentane, 190g of styrene, and 300g of butadiene into a 5L polymerization kettle, then add 0.54mol of ethyl tetrahydrofurfuryl ether and 27.8mol of tetrahydrofuran, and stir for 10min. The temperature was raised to 40° C., and then 0.48 mol of n-butyllithium was added. See Table 1 for the specific raw material ratio.

[0043] About 0.5 hours after the start of the reaction, the temperature of the polymerization tank rose to the highest point of about 68°C. The reaction was continued at this temperature for about 2.5 hours, and then terminated with ethanol.

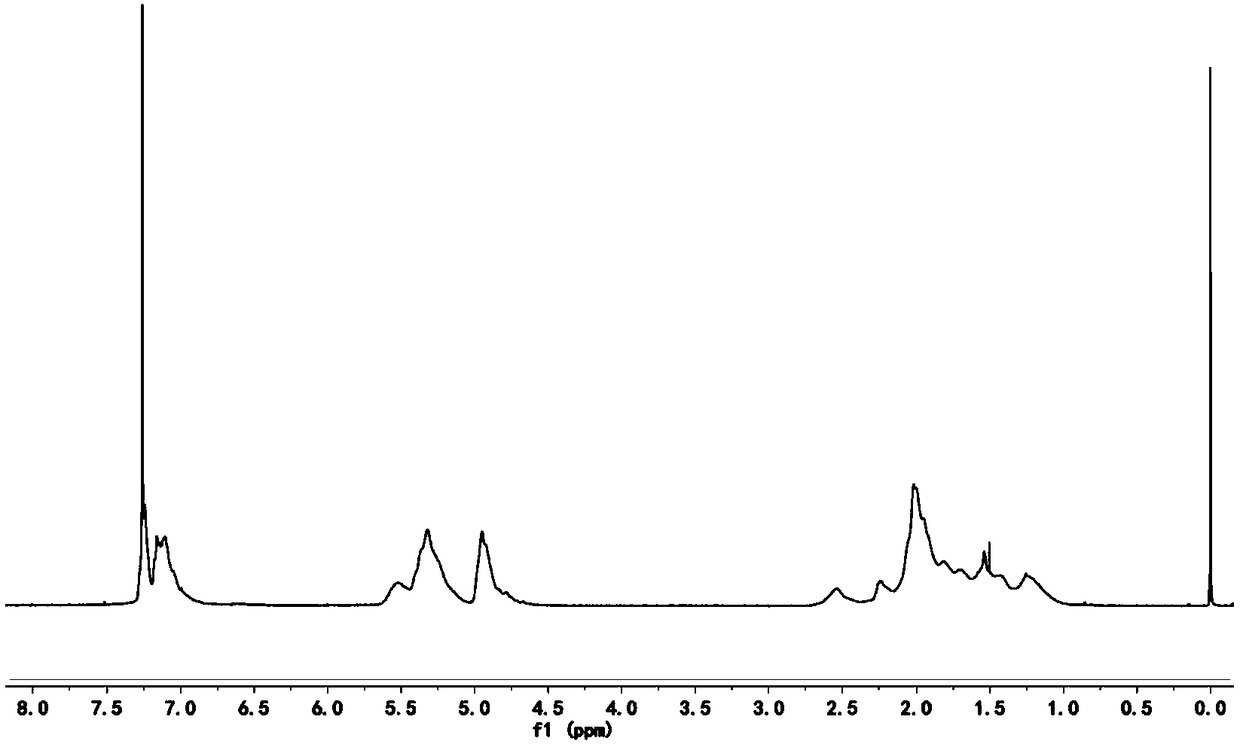

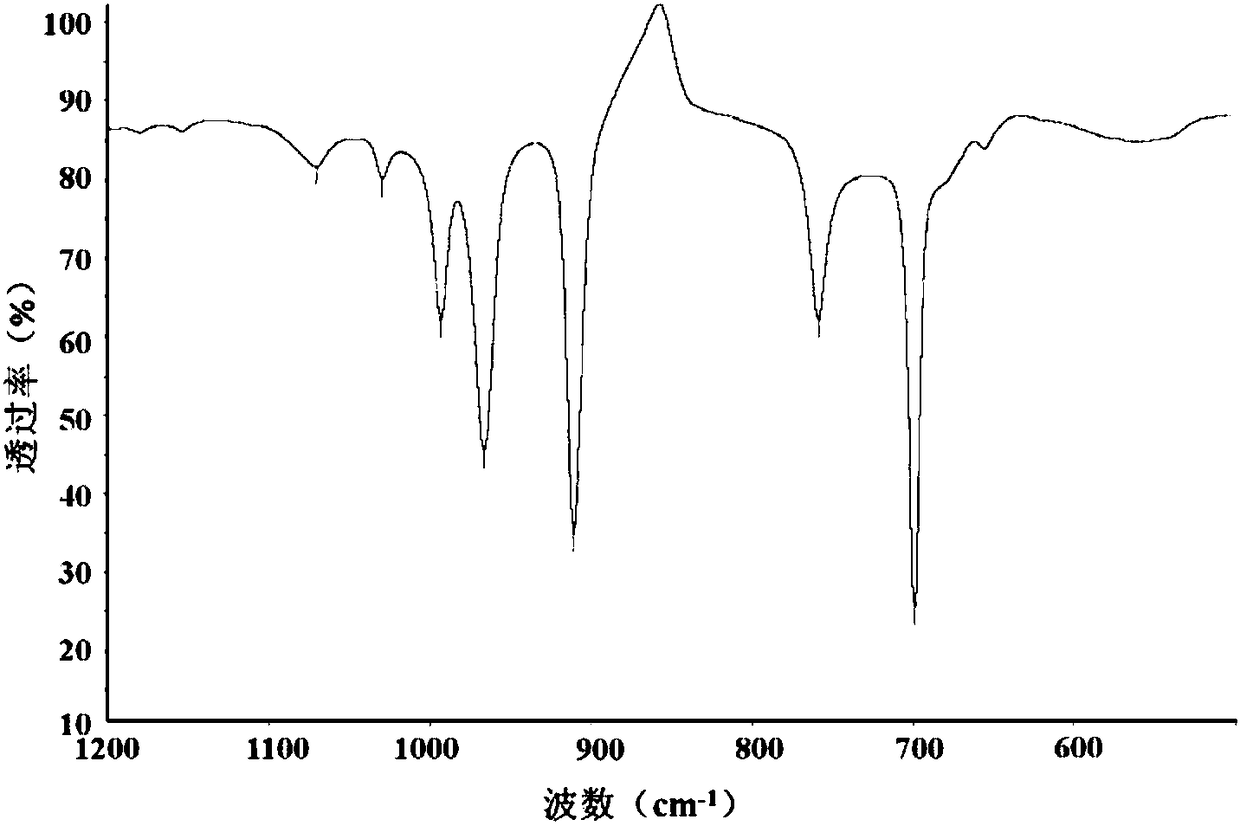

[0044] The styrene-butadiene rubber that present embodiment makes 1 H-NMR spectrum as figure 1 As shown, the infrared spectrum is shown in figure 2 As shown, after calculation, the styrene content is 37.8%, the vinyl content is 36.3%, and the degree of randomness is 100%. The specific results are shown in Table 2, which illustrates that the method pro...

Embodiment 2

[0046] Under the protection of high-purity nitrogen, add 2000g cyclopentane, 190g styrene, and 300g butadiene to the reactor, then add 0.54mol of ethyl tetrahydrofurfuryl ether and 27.8mol of tetrahydrofuran, and stir for 10min. Warm up to 40°C, and then add 0.40mol of n-butyllithium. See Table 1 for the specific raw material ratio.

[0047] About 0.5 hours after the start of the reaction, the temperature of the reactor rose to the highest point of about 65°C, and the temperature was maintained to continue the reaction for about 3.5 hours, and then terminated with ethanol.

[0048] The styrene-butadiene rubber is tested and characterized, and the styrene-butadiene rubber obtained in the present embodiment has 1 H-NMR spectrum and figure 1 Approximately, the infrared spectrogram and figure 2 Approximately, after calculation, the styrene content is 37.5%, the vinyl content is 40.6%, and the degree of randomness is 100%. The results are shown in Table 2, illustrating that the ...

Embodiment 3

[0050] Under the protection of high-purity nitrogen, 2000g of cyclopentane, 170g of styrene, and 300g of butadiene were sequentially added to the reaction kettle, and then 0.54mol of ethyl tetrahydrofurfuryl ether and 23.7mol of tetrahydrofuran were added, and after stirring for 10min, the reaction kettle The temperature was raised to 40° C., and then 0.40 mol of n-butyllithium was added. See Table 1 for the specific raw material ratio.

[0051] About 0.5 hours after the start of the reaction, the temperature of the reactor rose to the highest point of about 71°C. The reaction was maintained at this temperature for about 1.5 hours, and then terminated with ethanol.

[0052] The styrene-butadiene rubber is tested and characterized, and the styrene-butadiene rubber obtained in the present embodiment has 1 H-NMR spectrum and figure 1 Approximately, the infrared spectrogram and figure 2 Approximately, after calculation, the styrene content is 36.1%, the vinyl content is 42.5%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com