Preparation method of hydroxyapatite/bioglass material for bone repair

A hydroxyapatite and bioglass technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problem of difficult to meet the performance requirements of biomedical materials, and achieve the effect of easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

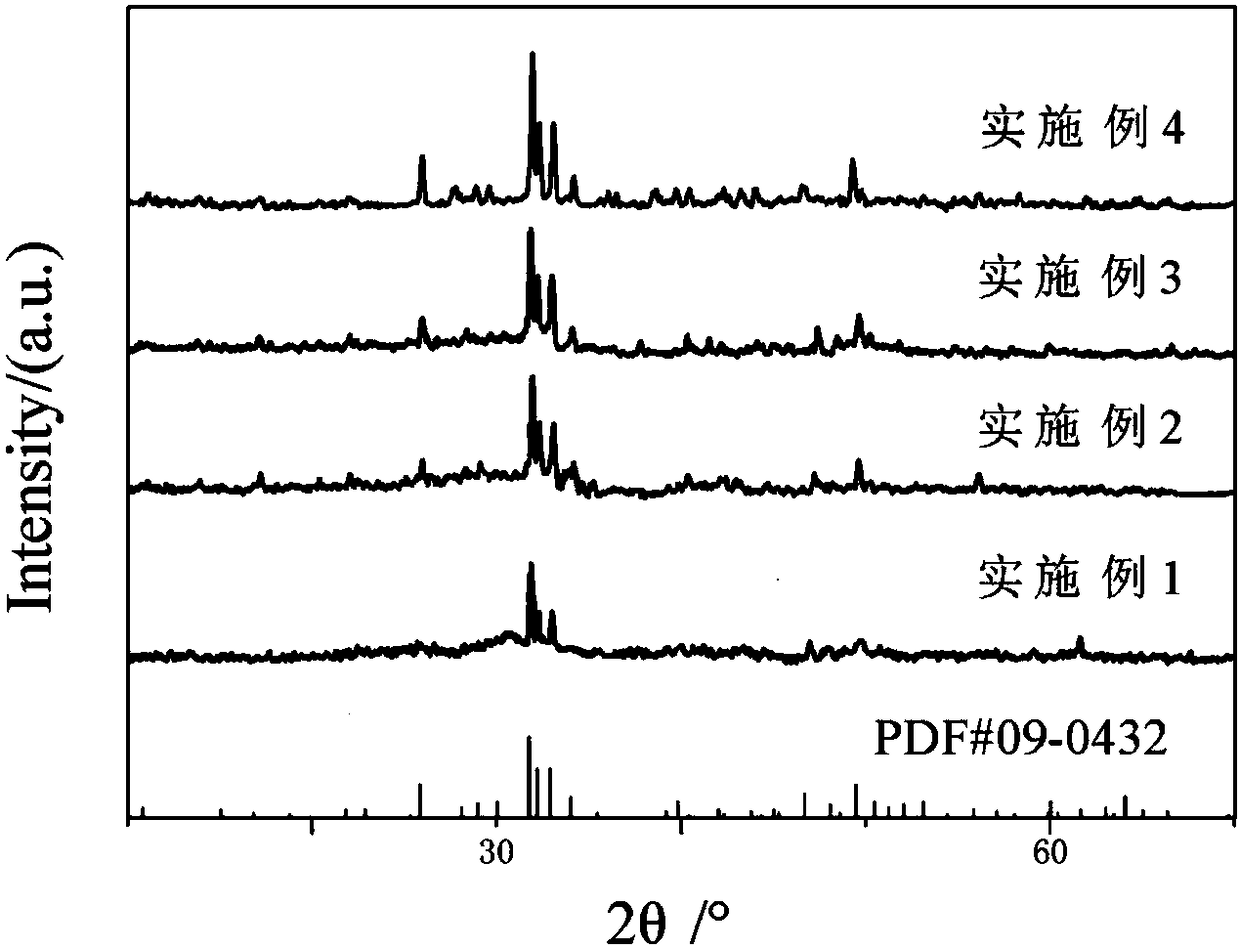

[0026] A method for preparing a hydroxyapatite / bioglass material for bone repair, comprising the following steps:

[0027] (1) Weigh calcium nitrate tetrahydrate and diammonium hydrogen phosphate in the laboratory with a molar ratio of Ca / P=1.67, first dissolve calcium nitrate tetrahydrate in water, then adjust the pH to 14 with concentrated sodium hydroxide, and then add The good diammonium hydrogen phosphate is mixed and stirred on a magnetic stirrer at 80°C for 2 hours; then aged at 100°C for 12 hours, then suction-filtered and dried to obtain hydroxyapatite;

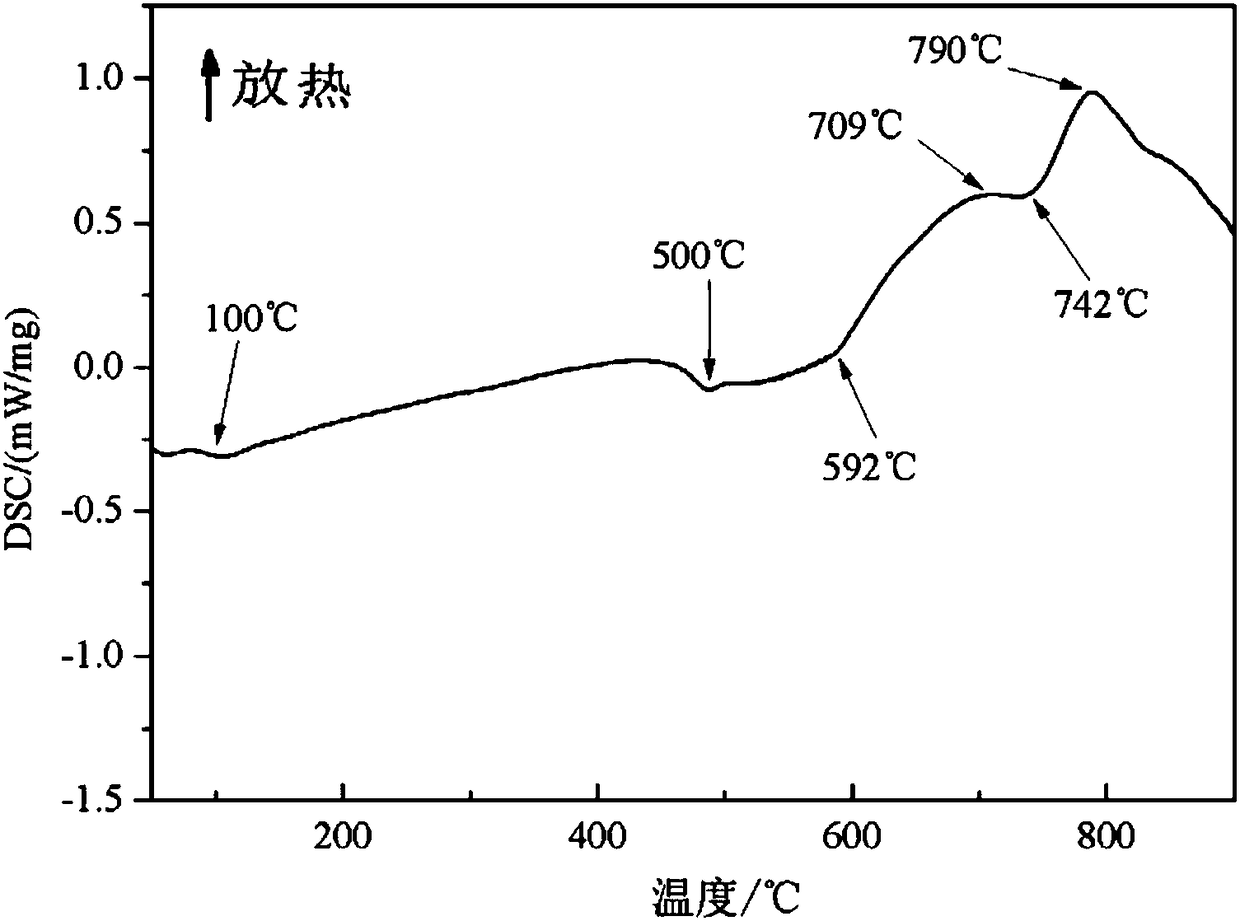

[0028] (2) Melting molten glass with a lifting furnace according to the formula of biological glass, then quenching the molten glass with water, drying the obtained glass, grinding it into powder, and obtaining biological glass powder for subsequent use; the biological glass is 13-93 biological glass ;

[0029] (3) Mix hydroxyapatite and biological glass powder according to the mass ratio of (1-4): (4-1), press and ...

Embodiment 1

[0032] (1) Weigh calcium nitrate tetrahydrate and diammonium hydrogen phosphate in the laboratory with a molar ratio of Ca / P=1.67, first dissolve calcium nitrate tetrahydrate in water, then adjust the pH to 14 with concentrated sodium hydroxide, and then add The good diammonium hydrogen phosphate is stirred after mixing, and stirred on a magnetic stirrer at 80°C for 2 hours, then aged at 100°C for 12 hours, and then dried by suction to obtain hydroxyapatite;

[0033] (2) According to 13-93 bioglass 36B 2 o 3 -18SiO2 2 -22CaO-6Na 2 O-MgO-8K 2 O-2P 2 o 5 Melt the molten glass with a lifting furnace, then quench the molten glass with water, dry the obtained glass, grind it into powder, and obtain biological glass powder for use;

[0034] (3) Weigh 2g of hydroxyapatite and biological glass powder according to the mass ratio of 1:4 for mixing, press molding under 20MPa pressure, and calcinate the sample at 670°C to obtain hydroxyapatite for bone repair stone / bioglass materia...

Embodiment 2

[0036] (1) Weigh calcium nitrate tetrahydrate and diammonium hydrogen phosphate in the laboratory with a molar ratio of Ca / P=1.67, first dissolve calcium nitrate tetrahydrate in water, then adjust the pH to 14 with concentrated sodium hydroxide, and then add The good diammonium hydrogen phosphate is stirred after mixing, and stirred on a magnetic stirrer at 80°C for 2 hours, then aged at 100°C for 12 hours, and then dried by suction to obtain hydroxyapatite;

[0037] (2) According to 13-93 bioglass 36B 2 o 3 -18SiO2 2 -22CaO-6Na 2 O-MgO-8K 2 O-2P 2 o 5 Melt the molten glass with a lifting furnace, then quench the molten glass with water, dry the obtained glass, grind it into powder, and obtain biological glass powder for use;

[0038] (3) Weigh 2 g of hydroxyapatite and biological glass powder according to the mass ratio of 2:3 for mixing, press molding under a pressure of 20 MPa, and calcinate the sample at 670 ° C to obtain hydroxyapatite for bone repair stone / bioglas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com