Treatment process for degrading dye waste water by ozone catalysis

A technology of dye wastewater and treatment process, which is applied in the direction of oxidation water/sewage treatment, textile industry wastewater treatment, water/sewage treatment, etc. It can solve the problems of difficult recovery of heterogeneous catalysts, unstable treatment effect, and difficult wastewater treatment. , to achieve the effect of improving recyclability, easy control of reaction conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The preparation of magnetic chitosan substrate

[0034] 1. Magnetic Fe 3 o 4 Preparation of nanoparticles: Preparation of Fe by chemical co-precipitation method 3 o 4 Nanoparticles: in N 2 Under protection, according to the molar ratio of 1:1.8 FeCl 2 4H 2 O and FeCl 3 ·6H 2 Dissolve O in distilled water and mix thoroughly under the action of magnetic stirring; heat the above solution to 90°C, press FeCl 2 4H 2 O and NH 3 The molar ratio of the solution is 1:10, add ammonia water dropwise therein, and react for 1h at a rotating speed of 600rpm. After the reaction is completed, it is separated by a magnet and washed repeatedly with distilled water until the solution is neutral, and then vacuum-dried to obtain an average particle size of 32nm. Magnetic Fe 3 o 4 nanoparticles.

[0035] 2. SiO2 2 encapsulated magnetic Fe 3 o 4 Preparation of nanoparticles: To avoid magnetic Fe 3 o 4 During the process of loading on chitosan, the nanoparticles ...

Embodiment 2

[0037] Example 2 Chromium-doped CeO 2 Preparation of nanorods

[0038] Weigh 0.7g Ce(NO 3 ) 3 ·6H 2 O and 6.2g NaOH were dissolved in 5mL and 35mL deionized water respectively, after mixing the two solutions, 0.15g CrCl was added to it 3 ·6H 2 O, after stirring evenly, transfer it to a 100mL hydrothermal reaction kettle, react at 100°C for 10-12h, filter after cooling, wash with absolute ethanol and deionized water three times, and dry at 60°C for 10h to obtain a yellow powder that is Cr Doped CeO 2 Nano stave.

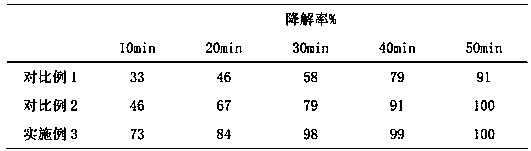

Embodiment 3

[0039] The preparation of embodiment 3 ozone catalytic degradation dye wastewater catalyst

[0040] The Cr-doped CeO that embodiment 2 makes 2 The nanorods were dispersed in distilled water and ultrasonically dispersed into a suspension, then added to 200 mL of the chitosan base solution prepared in Example 1, ultrasonicated at 40°C for 20min, and then adjusted to a water bath temperature of 60°C and a system pH of 9 , stirred for 4h to obtain the catalyst; wherein Cr-doped CeO 2 The mass ratio of nanorods to chitosan substrate is 1:13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com