Catalyst with low-temperature activity for purification of volatile organic pollutants and preparation method

A volatile organic and catalyst technology, applied in the field of catalyst preparation, can solve the problems of high light-off temperature, removal of unfavorable organic pollutant species, high production cost of catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

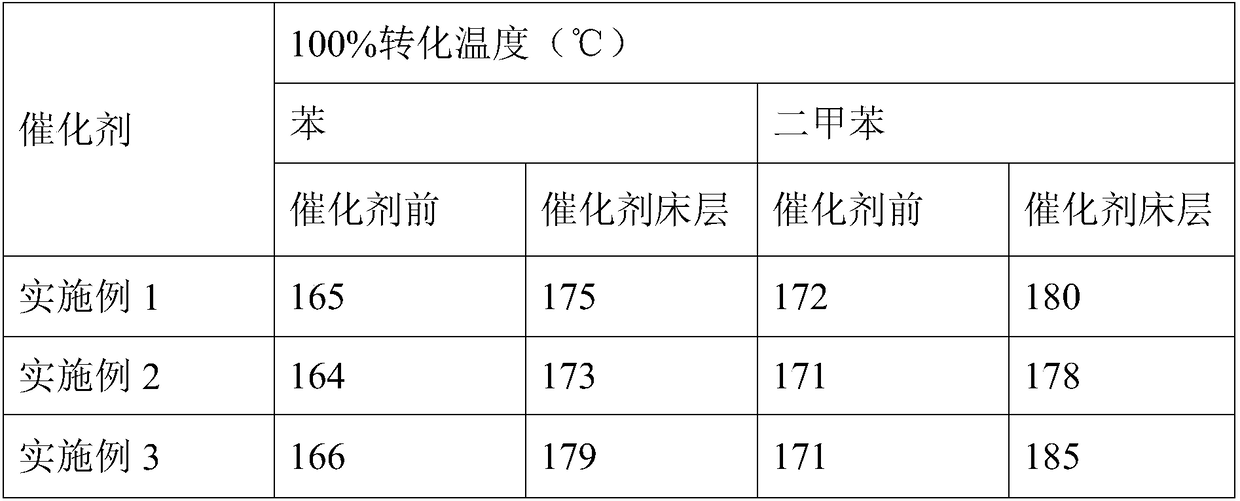

Examples

Embodiment 1

[0026] Embodiment one: a kind of preparation method of organic pollutant catalytic oxidation catalyst, comprises the steps:

[0027] Mn-Ce-Zr composite oxide synthesis steps:

[0028] (1) Take C according to the molar ratio of 0.25:0.6:0.15 4 h 6 MnO 4 4H 2 O, Ce(NO 3 ) 3 .6(H 2 O), Zr(NO 3 ) 4 ·5H 2 O, respectively 25 parts by weight, 60 parts by weight, 15 parts by weight, mixed and stirred;

[0029] (2) Take 150 parts by weight of citric acid, slowly drop into the above mixed solution, and stir for 2-5 hours after adding;

[0030] (3) Add 15 parts by weight of polyethylene glycol, slowly drop into the above mixed solution, after adding, stir for 6-12 hours, and stand still for 12 hours;

[0031] (4) Suction filtration, take the powder part, dry at 100-120°C for 10 hours, decompose at 280-350°C for 1 hour, and roast at 450-550°C for 5 hours. The total mass of the powder is not less than 800g.

[0032] Slurry configuration steps:

[0033] (1) Weighing of material...

Embodiment 2

[0039] Embodiment two: a kind of preparation method of catalytic oxidation catalyst of organic pollutants, comprises the following steps:

[0040] Mn-Ce-Zr composite oxide synthesis steps:

[0041] (1) Take C according to the molar ratio of 0.55:0.3:0.15 4 h 6 MnO 4 4H 2 O, Ce(NO 3 ) 3 .6(H 2 O), Zr(NO 3 ) 4 ·5H 2 O, respectively 55 parts by weight, 30 parts by weight, 15 parts by weight, mixed and stirred;

[0042] (2) Take 150 parts of citric acid, slowly add it dropwise to the above mixed solution, after adding, stir for 2-5 hours;

[0043] (3) Add 15 parts of polyethylene glycol, slowly drop into the above mixed solution, after the addition is complete, stir for 6-12 hours, and stand still for 12 hours;

[0044] (4) Suction filtration, take the powder part, dry at 100-120°C for 10 hours, decompose at 280-350°C for 1 hour, and roast at 450-550°C for 5 hours. The total mass of the powder is not less than 800g.

[0045] Slurry configuration steps:

[0046] (1) We...

Embodiment 3

[0052] Embodiment three: a kind of preparation method of catalytic oxidation catalyst of organic pollutants, comprises the following steps:

[0053] (1) Take C according to the molar ratio of 0.35:0.5:0.15 4 h 6 MnO 4 4H 2 O, Ce(NO 3 ) 3 .6(H 2 O), Zr(NO 3 ) 4 ·5H 2 O, respectively 35 parts, 50 parts, 15 parts, mixed and stirred;

[0054] (2) Take 150 parts of citric acid, slowly add it dropwise to the above mixed solution, after adding, stir for 2-5 hours;

[0055] (3) Add 15 parts of polyethylene glycol, slowly drop into the above mixed solution, after the addition is complete, stir for 6-12 hours, and stand still for 12 hours;

[0056] (4) Suction filtration, take the powder part, dry at 100-120°C for 10 hours, decompose at 280-350°C for 1 hour, and roast at 450-550°C for 5 hours. The total mass of the powder is not less than 800g.

[0057] Slurry configuration steps:

[0058] (1) Weighing of materials: Weigh Al respectively according to the weight ratio of 0.25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com