A kind of polymer chelating agent and preparation method thereof

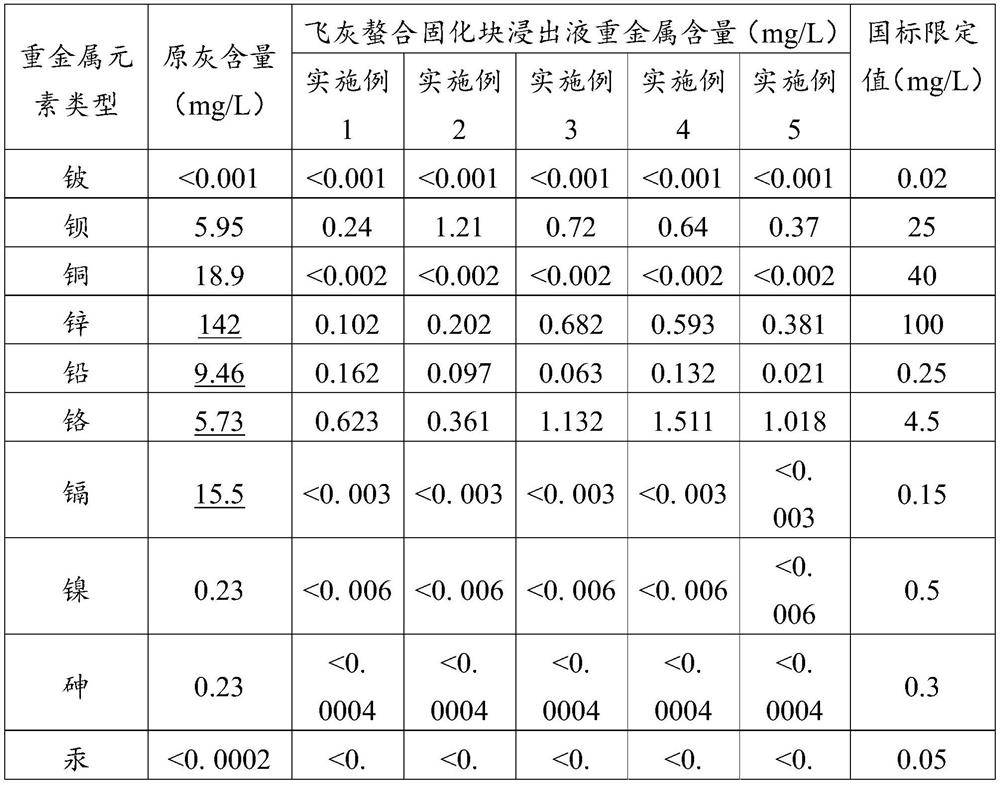

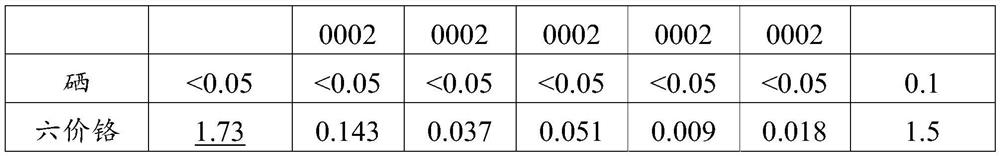

A polymer chelating agent, acrylamide technology, applied in the direction of the protection device against harmful chemicals, etc., can solve a large number of problems, and achieve the effect of low drug cost, low landfill cost and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

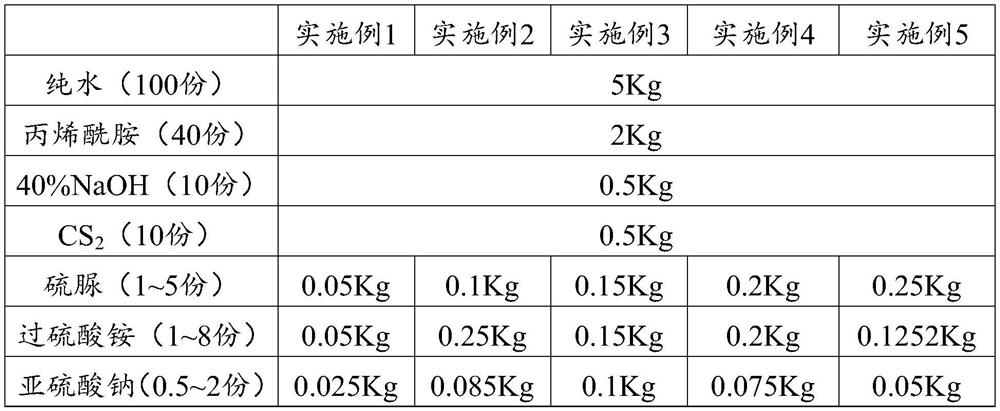

[0032] The present invention also provides a kind of preparation method of polymer chelating agent, comprises the following steps:

[0033] A. Add 1 to 5 parts of thiourea, 40 parts of acrylamide and 100 parts of pure water into the reactor in sequence, and stir at 12°C until completely dissolved to obtain an aqueous solution of acrylamide;

[0034] B. Put 10 copies of CS 2 Add to the aqueous acrylamide solution obtained in step A, and continue to stir for 60 minutes below 20°C;

[0035] C. Heat up to 40°C and keep at a constant temperature for 1 hour;

[0036] D. Continue to heat up to 80°C, add 0.5-2 parts of sodium sulfite and 1-8 parts of ammonium persulfate simultaneously, react for 1 hour, cool down to room temperature, add 10 parts of 40% NaOH dropwise evenly, and stir at room temperature for 30 minutes , to obtain a polymer chelating agent.

[0037] Preferably, the step A is specifically:

[0038] Add 0.5-4 parts of thiourea, 40 parts of acrylamide and 100 parts of...

Embodiment 1

[0052] Prepare the preparation steps of polymer chelating agent solution:

[0053]A1. Add 0.05Kg of thiourea (1 part), 2Kg of acrylamide (40 parts) and 5Kg of pure water (100 parts) into the reactor in sequence, start stirring until completely dissolved to obtain an aqueous solution of acrylamide, and control the system temperature to 12°C during the process .

[0054] B1. Add 0.5Kg CS2 (10 parts) evenly into the aqueous solution of A, control the temperature not to exceed 20°C and keep stirring for 60 minutes;

[0055] C1. Heat up to 40°C and keep the temperature constant for 1 hour;

[0056] D1. Continue to heat up to 80°C, simultaneously add 0.025Kg sodium sulfite (0.5 part) and 0.05Kg ammonium persulfate (1 part) simultaneously, react for 1 hour, cool down and evenly add 10 parts of 0.5Kg40% NaOH dropwise, stir at room temperature for 30 Minutes end, obtain the polymer chelating agent solution 1 that can be used for the heavy metal chelation of heavy metal chelation, sta...

Embodiment 2

[0058] The component selection and preparation steps of this embodiment 2 are basically the same as those of embodiment 1, except that:

[0059] Thiourea: 0.1Kg;

[0060] Ammonium persulfate: 0.25Kg;

[0061] Sodium sulfite: 0.085Kg;

[0062] Obtain polymer chelating agent solution 2, set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com