Nano-ceramic coating and its preparation and construction technology for 600°C-resistant operating vehicles

A technology of nano-ceramics and working vehicles, applied in the field of coatings, can solve problems such as production and construction personnel's health hazards, easy to burn and smoke, and pollute the environment, achieve corrosion resistance and hydrophobic self-cleaning enhancement, improve coating strength, Elimination of grain boundary impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

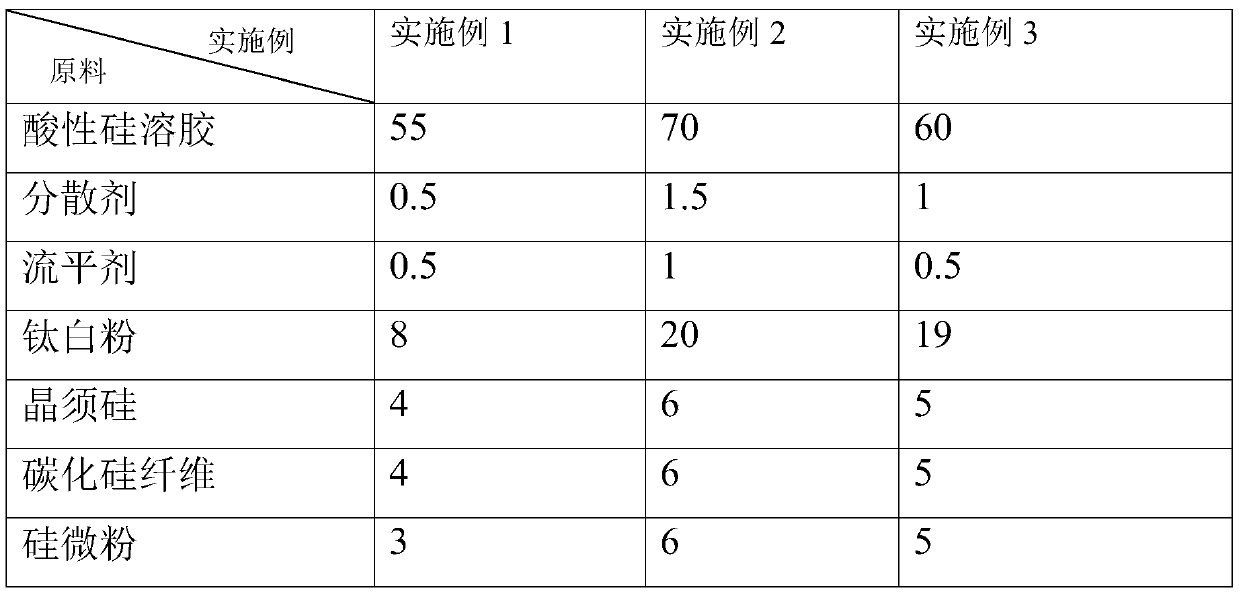

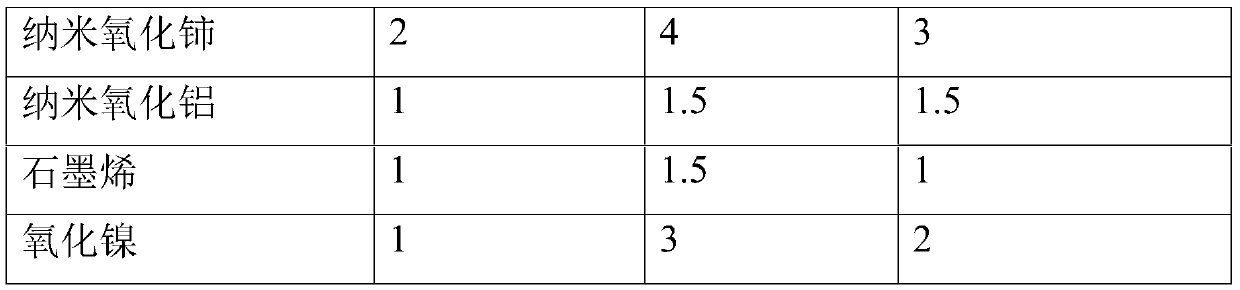

[0050] The weight composition of the raw materials of component A of nano-ceramic coating for 600°C-resistant operating vehicles is shown in the following table:

[0051]

[0052]

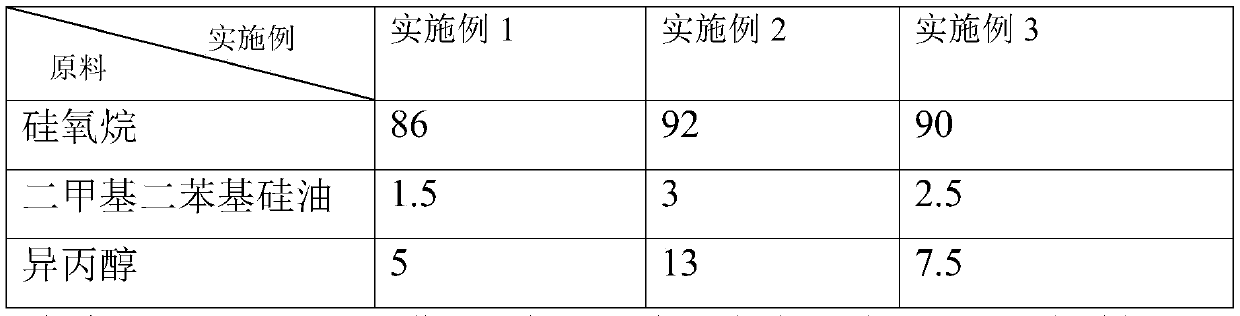

[0053] The weight and composition of raw materials of component B of nano-ceramic coatings for 600°C-resistant operating vehicles are shown in the table below:

[0054]

[0055] The 600°C-resistant nano-ceramic coating for working vehicles of Examples 1-3 is prepared by the following method:

[0056] Add acidic silica sol, dispersant, and leveling agent to the sand mill in sequence in proportion, and then add titanium dioxide, whisker silicon, silicon carbide fiber, silicon micropowder, nano-cerium oxide, nano-alumina, and nickel oxide to the car. grind. When the fineness is less than 25μm, get off the car and calculate the yield, then add graphene under stirring with a high-speed mixer at a speed of 650r / min, after stirring for 15-20min, pass through a 160-mesh double-layer sieve to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com