One-pot liquefaction process of coal and biomass

A biomass and process technology, applied in the field of coal and biomass co-smelting process, can solve the problems of low liquefaction efficiency, unrealized mixing production technology, limited coal powder content, etc., achieve high fluidity, and realize clean and efficient utilization , the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

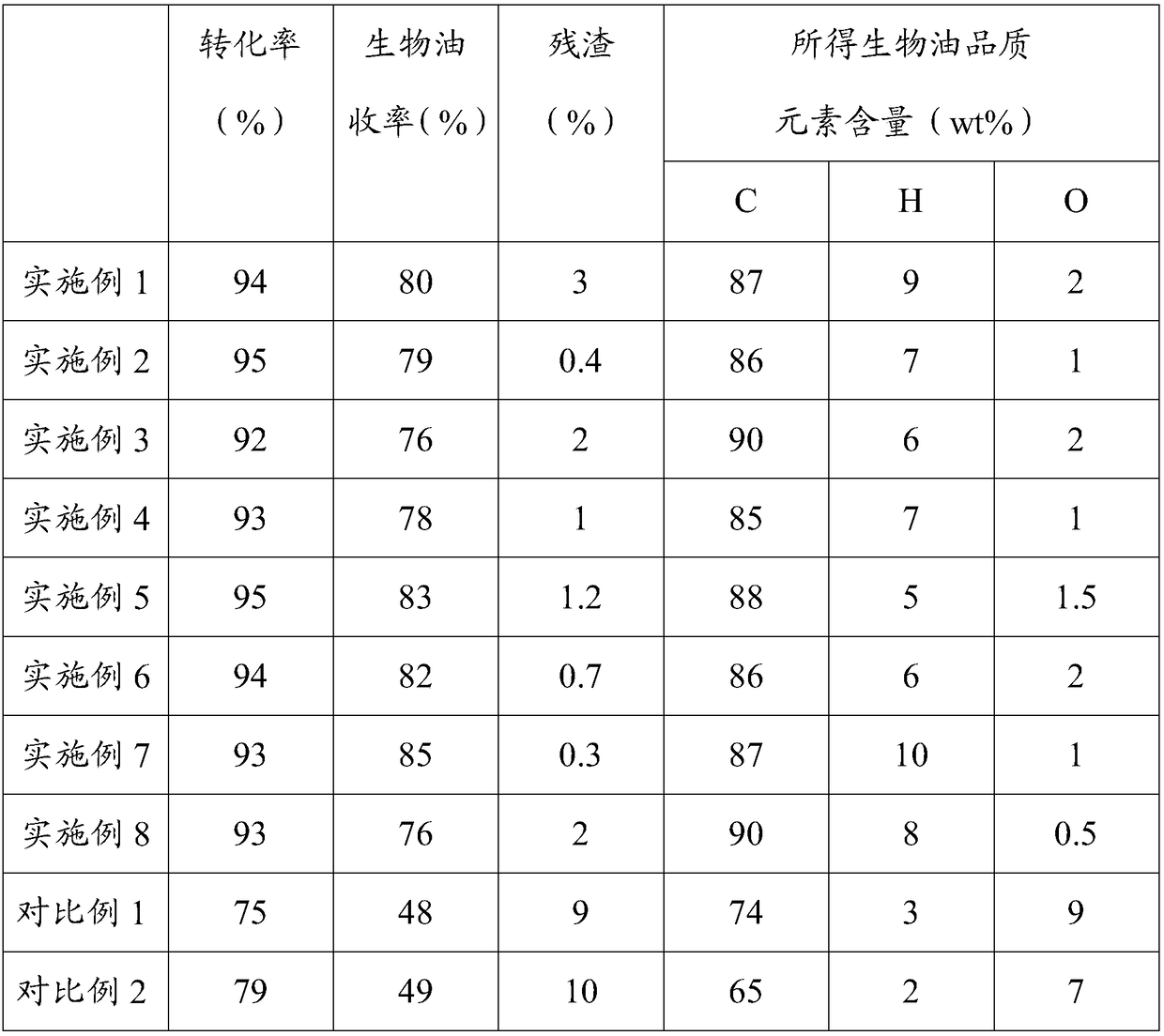

Examples

Embodiment 1

[0071] The present embodiment provides a kind of preparation method of the second catalyst, comprising the following steps:

[0072] Preparation of biochar carrier:

[0073] Use H + The acidic medium with a concentration of 5mol / L, acidified the biochar at 80°C with a volume ratio of 15:1 for 10 hours to obtain a biochar carrier; as another alternative, OH can also be used - The alkaline medium with a concentration of 0.5mol / L acidified the biochar at a volume ratio of 5:1 at 30°C for 10h.

[0074] Loading of the second active ingredient:

[0075] The oxides of Mo and W and the biomass charcoal carrier are vibrated and ground together to realize the loading of active components on the biochar carrier, and obtain the second catalyst with a particle size of 100 μm-200 μm. Based on the mass of metal elements, the second active component accounts for 5% of the mass of the biochar carrier.

Embodiment 2

[0077] The one-pot liquefaction process of coal and biomass provided in this embodiment comprises the following steps:

[0078] Straw pretreatment:

[0079] Take corn stalks, dry and dehydrate them to a moisture content of 1 wt%, crush them to a median particle size of 100 μm, and then send them to a plodder for extrusion molding at a molding pressure of 2 MPa to obtain compressed straw materials;

[0080] Send the straw compressed material into a hammer mill for crushing to obtain straw crushed material with a particle size of 50 μm, which is ready for use.

[0081] Pretreatment of coal raw materials:

[0082] Take lignite, dry and dehydrate it, pulverize until the median particle size is 50 μm, and then send it to a briquetting machine for extrusion molding, and the molding pressure is 5 MPa to obtain lignite compressed material;

[0083] Send the compressed lignite material into a ball mill for pulverization to obtain a pulverized lignite material with a median partic...

Embodiment 3

[0088] The one-pot liquefaction process of coal and biomass provided in this embodiment comprises the following steps:

[0089] Pretreatment of biomass raw materials:

[0090] (1) Get the reed, dry it to a water content of 1wt%, and then send it into the jet mill for crushing to obtain the primary crushed material of the reed, with a particle size of D 50 is 200 μm.

[0091] (2) Send the reed primary pulverized material into a briquetting machine or a plodder for extrusion molding with a molding pressure of 3 MPa to obtain a reed compressed material.

[0092] (3) The reed compressed material is sent into the jet mill, and secondary pulverization is carried out to obtain the reed secondary pulverization material, particle size D 50 40 μm, set aside.

[0093] Pretreatment of coal raw materials:

[0094] (1) Take Shendong long-flame coal, dry and dehydrate it, and then send it to a ball mill for crushing to obtain primary crushed material of Shendong long-flame coal, part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com