Hydrocarbon catalytic cracking method with high yield of gasoline

A catalytic cracking and gasoline technology, which is applied in the field of hydrocarbon catalytic cracking of prolific gasoline, can solve problems such as difficult process control, and achieve the effects of adjustable pore volume, excellent activity, and improved catalytic cracking selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

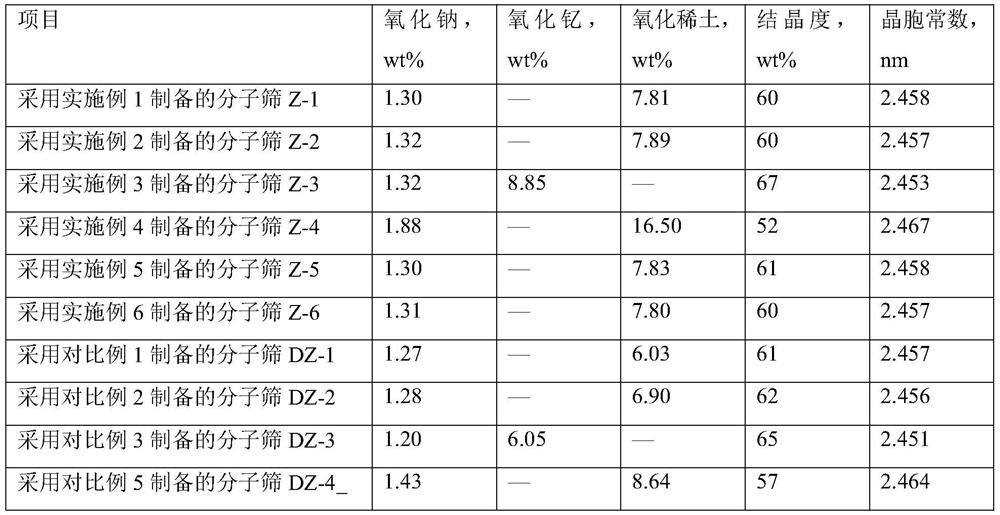

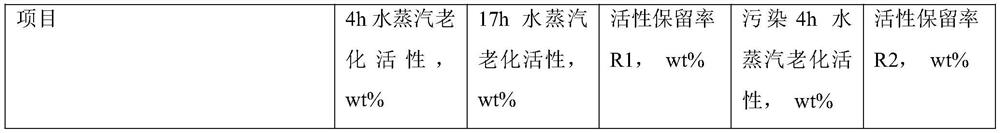

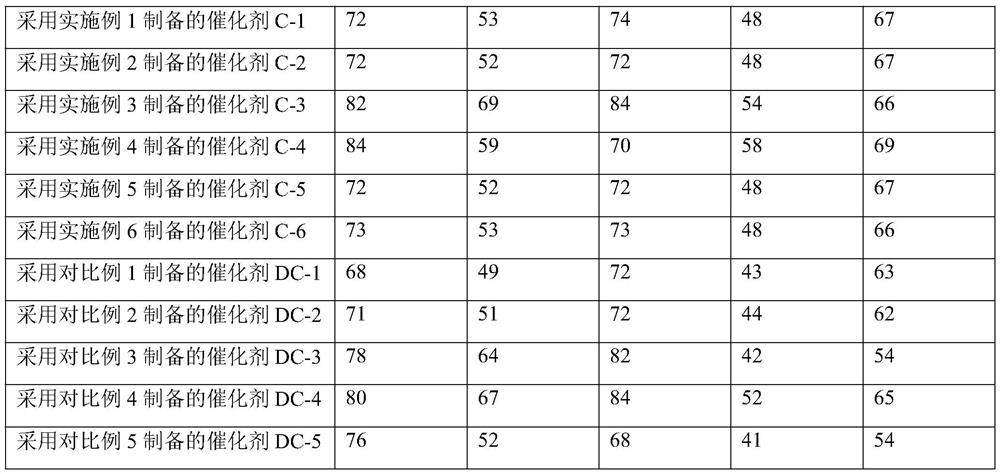

[0058] (1) Add 1000g NaY molecular sieve (dry basis) into 7L deionized water, under stirring, add 350g ammonium chloride, adjust the pH value of the slurry to 3.50 with hydrochloric acid, stir at 85°C for 1h, then filter and wash, the obtained filter cake and 250mL of rare earth chloride and 2.2L of deionized water were mixed, stirred for 0.5h, spray-dried, and then hydrothermally roasted in a roaster under a 100% steam atmosphere at a roasting temperature of 600°C for 2 hours.

[0059](2) Continue to mix the molecular sieve obtained in step (1) with ammonium chloride and water according to the weight ratio of molecular sieve (dry basis): ammonium salt: water = 1:0.3:7 to form a slurry. Stir under the conditions for 1 hour, add 1% (relative to the molecular sieve dry basis) cationic polyacrylamide, stir for 5 minutes, then add ammonium carbonate, the amount of ammonium carbonate added meets the weight ratio of ammonium carbonate: IIIB group elements (calculated as oxides) = 0....

Embodiment 2

[0063] (1) Except that no filter aid cationic polyacrylamide was added to the molecular sieve slurry exchanged with ammonium salt in step (2) of Example 1, other conditions were the same as in Example 1 to obtain molecular sieve Z-2 of the present invention.

[0064] (2) Add 600g (dry basis) of molecular sieve Z-2 into 1.2L of deionized water, and perform sand milling so that the median particle size D(v, 0.5) of the molecular sieve is less than 5 μm to obtain molecular sieve slurry Z-2J. Mix 425g of alumina sol, 1972g of kaolin, 943g of pseudoboehmite, and 4.9L of water for beating, add 50mL of hydrochloric acid, heat up to 50°C, stir for 1 hour, then cool down to 25°C, add molecular sieve slurry Z-2J, and stir for 15 minutes , then add 240g alkaline silica sol, 180mL water glass, the pH value of the final slurry is 3.57, continue to stir for 30 minutes, after homogeneous spray drying molding, roasting, washing, drying, the catalyst C-2 of the present invention is obtained.

Embodiment 3

[0075] (1) Add 2000g of NaY molecular sieve (dry basis) into 20L of deionized water, under stirring, add 600g of ammonium sulfate, adjust the pH value of the slurry to 3.45 with hydrochloric acid, stir at 90°C for 1h, then filter and wash, the obtained filter cake is the same as 542g Yttrium nitrate and 4.8L deionized water were mixed to make NaY molecular sieve (dry basis): the weight ratio of yttrium compound (in terms of yttrium oxide) was 1:0.08, stirred for 0.5h, spray-dried, and heated in a roasting furnace under 100% water vapor Hydrothermal calcination was carried out under the atmosphere, the calcination temperature was 620° C., and the calcination time was 1.5 hours.

[0076] (2) Mix the molecular sieve, ammonium sulfate and water obtained in step (1) according to the weight ratio of molecular sieve (dry basis): ammonium salt: water = 1:0.3:5 to form a slurry. Stir for 1 hour, add 0.02% (relative to the molecular sieve dry basis) cationic polyacrylamide and ammonium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com