A carbon nanotube/secondary anodized tio 2 Nanotube photocatalyst material and its preparation method and application

A technology of secondary anodic oxidation and carbon nanotubes, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of high cost and achieve cost reduction, high purity, and high-efficiency Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

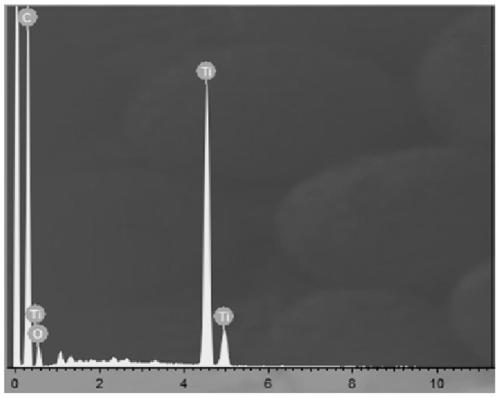

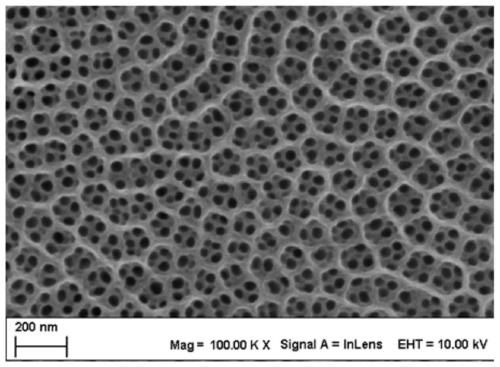

[0047] The invention provides a carbon nanotube / anodized TiO 2 The preparation method of nanotube photocatalyst material, described preparation method comprises the steps:

[0048] (1) Preparation of anodized TiO 2 nanotube material. This preparation step can adopt the existing electrochemical anodic oxidation method or adopt the following method provided by the present invention: use the titanium sheet as the anode, the platinum sheet as the cathode, and the mixed solution composed of ammonium fluoride, ethylene glycol and water as the electrolyte, carry out electrolysis. Before electrolysis, the titanium sheet can be pretreated, and the pretreatment can be carried out as follows: the titanium sheet is ultrasonically cleaned in acetone, absolute ethanol and distilled water for 15-20 minutes, and then dried in nitrogen. The pretreated titanium sheet is connected to the positive electrode of the DC power supply as the anode, and the platinum sheet is connected to the negativ...

Embodiment 1

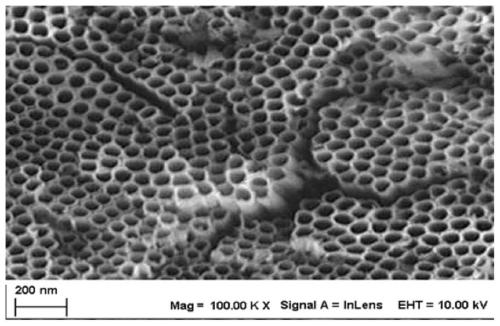

[0064] The titanium sheet was ultrasonically cleaned in acetone, absolute ethanol and distilled water for 15 min, and dried in nitrogen. Two-electrode system is adopted: the power supply adopts a DC stabilized power supply, and the titanium sheet is used as the anode to connect to the positive electrode of the DC power supply, and the platinum sheet (2cm×2cm) is connected to the negative electrode of the power supply as the counter electrode. 4 F+(CH 2 Oh) 2 +2vol%H 2 In the electrolyte solution composed of a mixed solution of O, the electrolysis was carried out at a constant voltage of 50V at room temperature, and the electrolysis time was 30min. After the reaction, the titanium sheet was rinsed with distilled water, placed in a muffle furnace in an air atmosphere, and the temperature was raised from room temperature to 450°C at a rate of 5°C / min, and the temperature was kept constant for 1h. The prepared primary anodized TiO 2 nanotube.

[0065] Will grow once anodized T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com