Co/Co3O4 composite and preparation method and application of Co/Co3O4 composite

A composite material and reaction technology, applied in the preparation of organic compounds, catalyst activation/preparation, preparation of aminohydroxy compounds, etc., can solve the problems of low conversion rate and selectivity, difficult to generate, etc., and achieve a simple and repeatable synthesis method. The effect of using the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1Co / Co 3 o 4 composite material

[0017] (1) Preparation method

[0018] 1)Co 6 (btb) 4 (4,4′-bipy) 3 Crystal preparation: 0.03g Co(NO 3 ) 2 and 0.01g H 3 Put btb in a 5ml glass bottle, add 2ml of N,N-dimethylformamide at the same time, ultrasonically treat for 20min, then put the 5ml glass bottle in an oven, and react for 72h at 85°C, after the reaction, remove the solution The liquid in the solution was washed with N,N-dimethylformamide, filtered, and the solid particles were placed in a vacuum drying oven at 80°C for vacuum drying.

[0019] 2)Co 6 (btb) 4 (4,4′-bipy) 3 Crystal activation: the Co 6 (btb) 4 (4,4′-bipy) 3 The crystals were placed in a vacuum drying oven at 120°C for 36 hours in vacuum to obtain the activated Co 6 (btb) 4 (4,4′-bipy) 3 Crystals, stored under nitrogen.

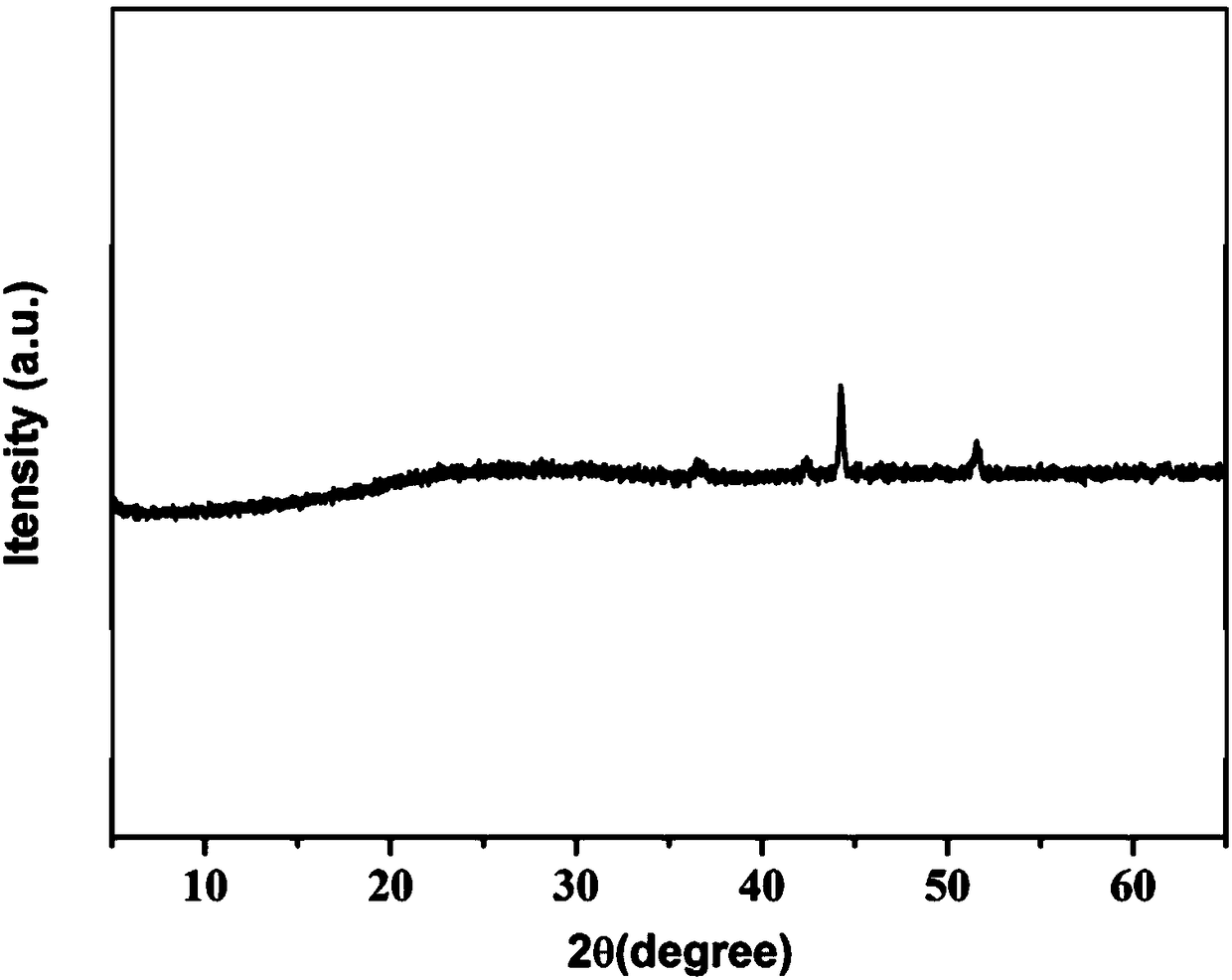

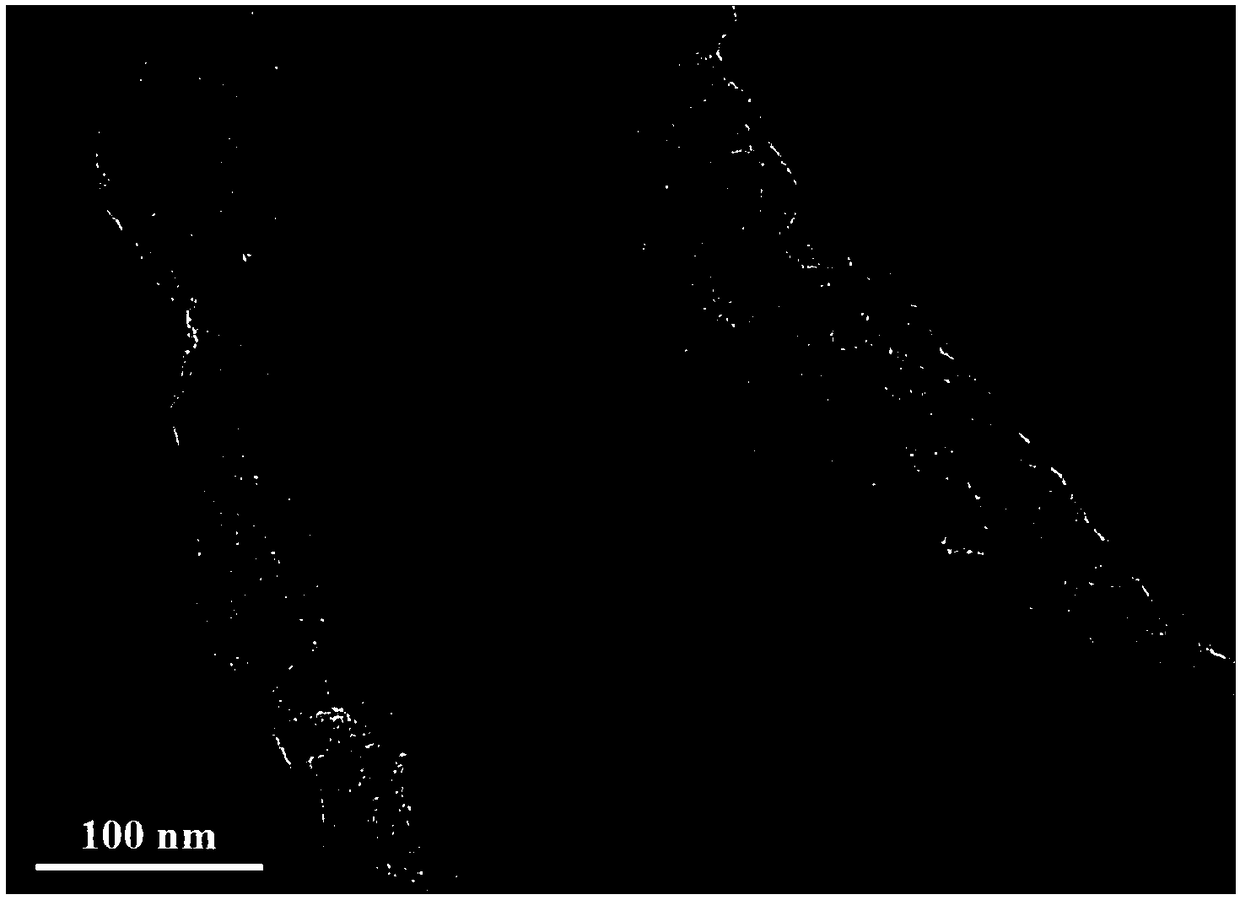

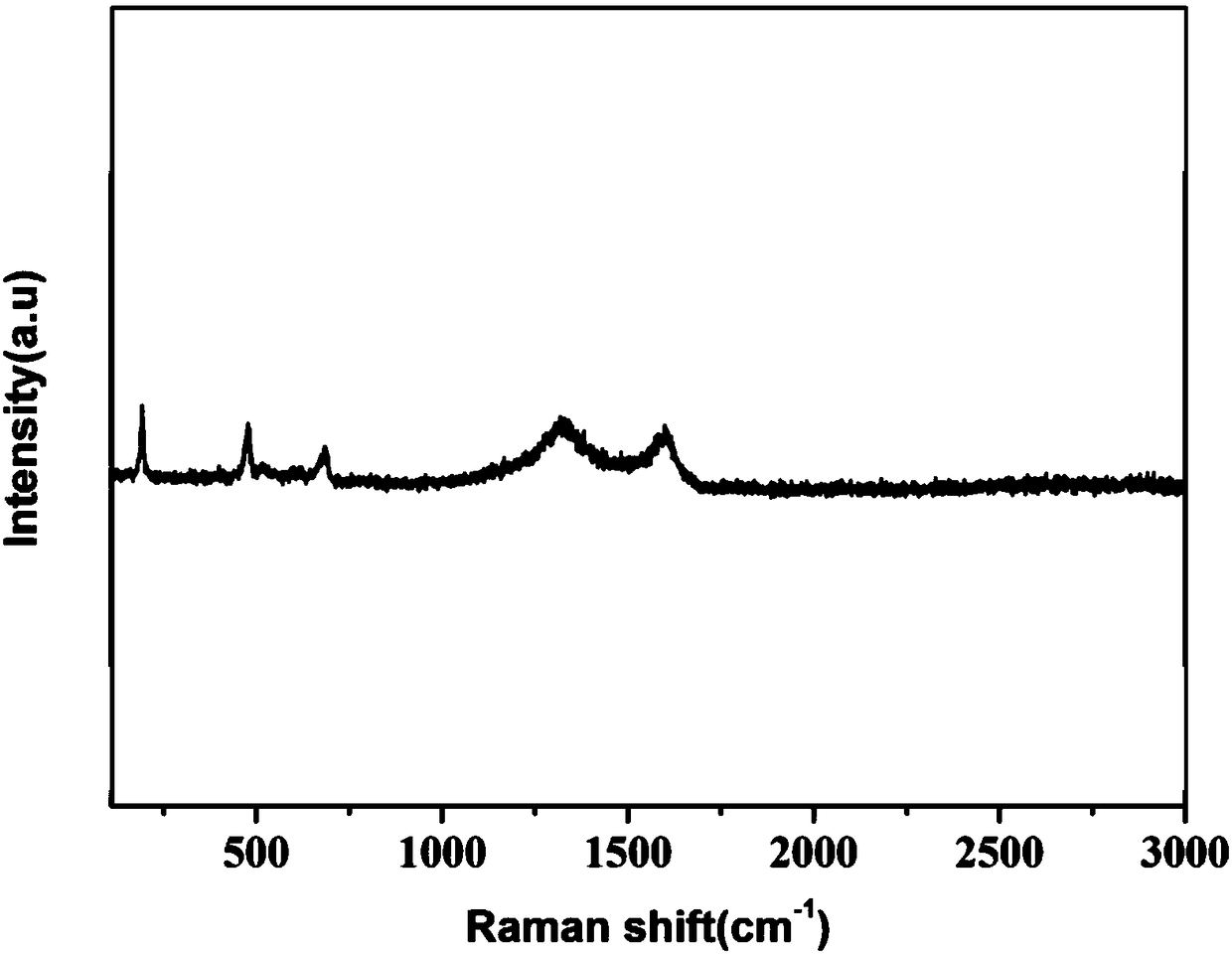

[0020] 3) will Co 6 (btb) 4 (4,4′-bipy) 3 Calcined in a tube furnace at 800 °C for 1 hour under nitrogen atmosphere to obtain Co / Co 3 o 4 composite material...

Embodiment 2

[0024] Example 2Co / Co 3 o 4 Composite Catalyzed Reduction of p-Nitrophenol

[0025] The method is as follows: 20ml of p-nitrophenol with a concentration of 50mg / L and 0.19g of sodium borohydride are dissolved in 30ml of water to obtain a mixed solution; 10mg of Co / Co prepared in Example 1 is added to the mixed solution 3 o 4 The composite material was placed in a 100mL Erlenmeyer flask, and the reaction device was fixed. React at room temperature, after reacting for 14min, get the reaction solution respectively and carry out the ultraviolet-visible light spectrophotometer to monitor, the result is as follows Figure 5 shown.

[0026] Figure 5 Co / Co synthesized for the present invention 3 o 4 The conversion rate diagram of the composite material after 0min and 14min of reaction. Depend on Figure 5 It can be seen that an absorption peak appears at a wavelength of 350nm at 0 min by ultraviolet analysis chromatography, and no product is generated at this time. When carr...

Embodiment 3

[0028] Example 3Co / Co 3 o 4 Composite material repeatability test

[0029]After the reaction of Example 2 is completed, the Co / Co 3 o 4 Composite material, repeat the experiment of embodiment 2 4 times. Image 6 It is the Co / Co synthesized in Example 1 3 o 4 The conversion rate diagram of the product after 0min and 14min in the fifth reduction reaction of p-nitrophenol catalyzed by the composite material. By repeating the experiment, the Co / Co of the fifth reaction 3 o 4 The conversion rate of the composite material is 95%, the selectivity of p-nitrophenol is 100%, and still has good catalytic activity and selectivity. Prove that the Co / Co synthesized by the present invention 3 o 4 Composite materials are highly recyclable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com