Enzyme particle for clothes cleaning soap as well as preparation method and application thereof

A technology for cleaning soap and enzymes, applied in the field of washing, can solve the problems of difficulty in ensuring the stability of enzyme particles, and it is difficult for enzymes to achieve the expected effect, etc., and achieves the effect of improving decontamination ability, improving washing effect and easy rinsing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

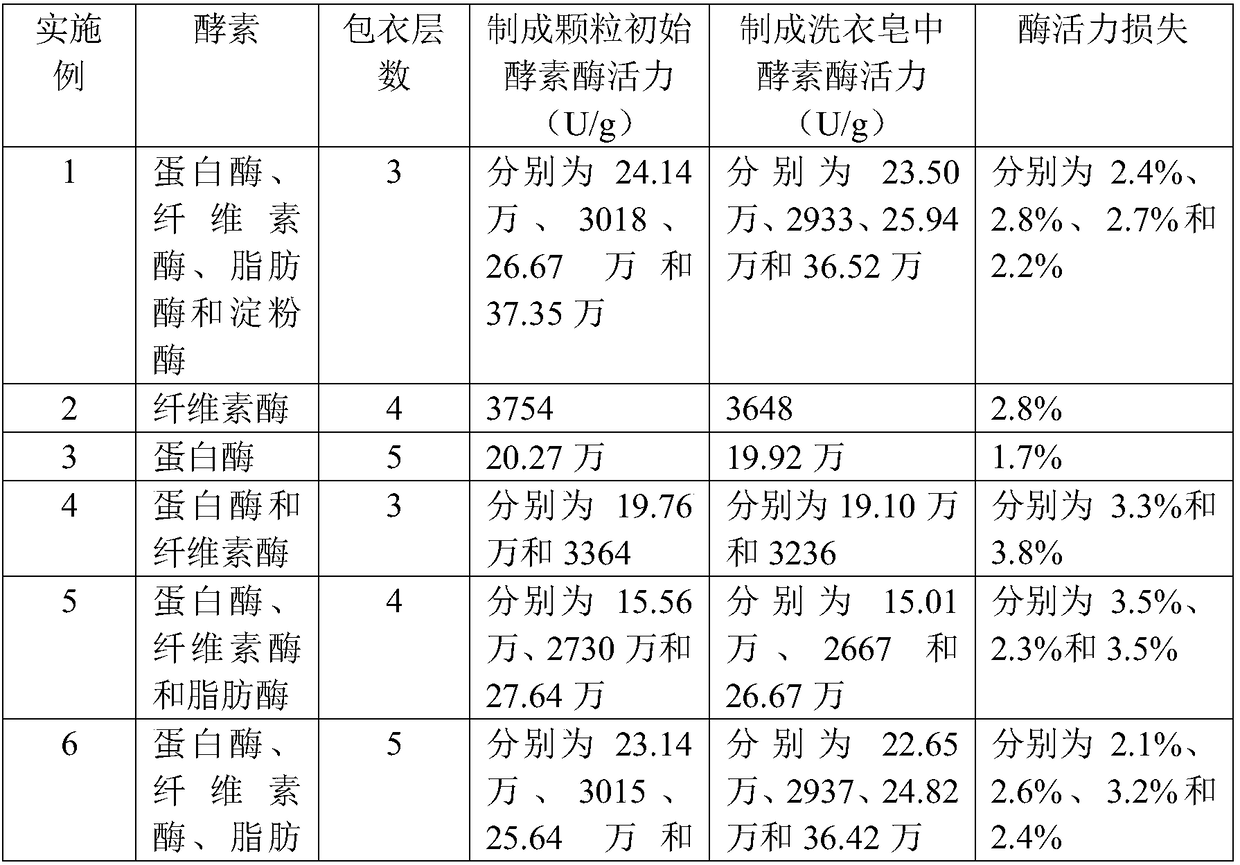

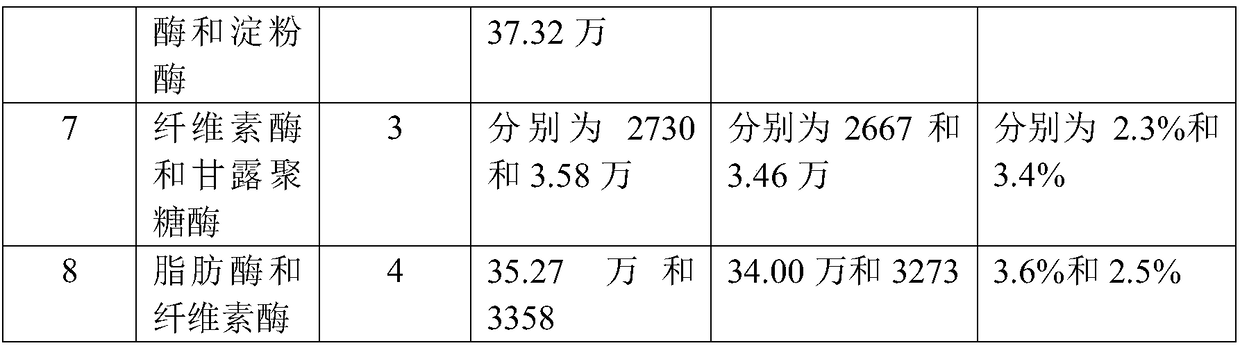

Embodiment 1

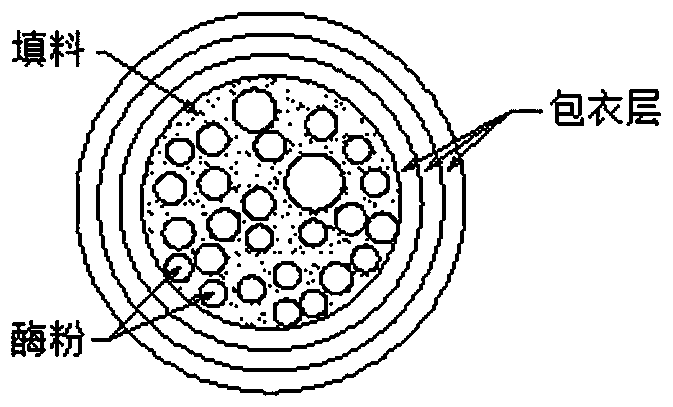

[0033] An enzyme granule for laundry cleaning soap, which is composed of a ball core and several layers of coating layers sprayed on the surface of the ball core; the weight percentage of the components contained in the soap enzyme granule is: 15% of the ball core, 85% of the coating coat layer;

[0034] The percentage by weight of the components contained in the ball core is: 34% protease; 15% cellulase; 6% lipase; 4% amylase, 1% polyamide, 3% calcium formate, 20% % clay, 17% starch;

[0035] The weight percent of the components contained in the coating layer is: 6% / 5% / 4% lead chrome yellow, 20% / 30% / 40% calcium silicate, 20% / 20% / 20% starch , 54% / 45% / 36% polyvinylpyrrolidone (PVP).

[0036] The method steps for preparing the enzyme granules for laundry cleaning soap are:

[0037] The enzyme or enzyme composition is sprayed into the tower from the nozzle of the centrifugal sprayer for atomization. After the mist meets the filler for the pellet core, it is quickly dried into ...

Embodiment 2

[0040] An enzyme granule for laundry cleaning soap, which is composed of a ball core and several layers of coating layers sprayed on the surface of the ball core; the weight percentage of the components contained in the soap enzyme granule is: 10% of the ball core, 90% of the coating coat layer;

[0041]The weight percent of the components contained in the ball core is: 70% cellulase, 10% clay, 17% starch, 2% amide;

[0042] The percentage by weight of the components contained in the coating layer is: 5% / 4% / 3% / 2.5% iron blue, 30% / 40% / 45% / 50% calcium formate, 20% / 20% / 25% / 25% starch, 45% / 36% / 27% / 22.5% polymethylacrylate.

[0043] The method steps for preparing the enzyme granules for laundry cleaning soap are:

[0044] The enzyme or enzyme composition is sprayed into the tower from the nozzle of the centrifugal sprayer for atomization. After the mist meets the filler for the pellet core, it is quickly dried into powder or tiny particles. The air inlet temperature is 80°C, and...

Embodiment 3

[0047] An enzyme granule for laundry cleaning soap, which consists of a ball core and several coating layers sprayed on the surface of the ball core; the weight percentage of the components contained in the protease enzyme granule for soap is: 2% of the ball core, 98% of the Coating layer;

[0048] The weight percent of the components contained in the ball core is: 70% protease, 3% calcium formate, 10% clay, 17% starch, 1% polyamide;

[0049] The percentage by weight of the components contained in the coating layer is: 5% / 4% / 3% / 2.5% / 2% iron blue, 30% / 40% / 45% / 50% / 55% sodium hydroxide , 10% / 10% / 15% / 15% / 15% hydroxypropyl cellulose, 55% / 46% / 37% / 32.5% / 28% polypropylene.

[0050] The method steps for preparing the enzyme granules for laundry cleaning soap are:

[0051] The enzyme or enzyme composition is sprayed into the tower from the nozzle of the centrifugal sprayer for atomization. After the mist meets the filler for the pellet core, it is quickly dried into powder or tiny par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com