Activated-carbon regeneration-gas pretreatment system device and pretreatment process method

A technology for regenerating gas and system devices, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of difficulty in processing, difficulty in reusing SO2, and complex composition of activated carbon regeneration gas, and achieves simple process and compact structure. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

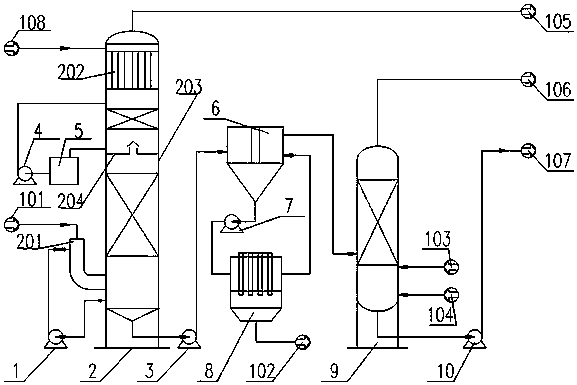

[0037] Embodiment 1: activated carbon regeneration gas pretreatment system device of the present invention, such as figure 1 As shown, the direction pointed by the arrow is the direction of the material; including the regenerative gas wet scrubbing system and the scrubbing liquid treatment system;

[0038] Wherein, the regenerated gas wet scrubbing system includes a wet scrubber 2, a scrubbing circulation pump 1, a scrubbing liquid discharge pump 3, a clear liquid pump 4, and a clear liquid tank 5; the scrubbing liquid treatment system includes a clarifier 6, a drain Mud pump 7, filter 8, ammonia stripper 9, brine discharge pump 10;

[0039] The wet scrubber 2 is respectively connected to the washing circulation pump 10, the washing liquid discharge pump 3, and the clear liquid tank 5, and the washing liquid discharge pump 3 is connected to the lower part of the wet scrubber 2, and the wet washing The upper part of the device 2 is connected with the clear liquid tank 5, the c...

Embodiment 2

[0059] The difference from Example 1 is that the outlet of the washing liquid discharge pump 3 is directly sent to the lower part of the ammonia stripper 7, and the bottom of the ammonia stripper 9 is connected with a brine discharge pump 10, and the brine is discharged through the brine discharge pump 10 for treatment.

[0060] The free ammonia separated by the ammonia stripper 9 is reused or sold as a by-product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com