Ce isomorphous substitution LTL molecular sieve and preparation method thereof

A technology of isomorphic substitution and molecular sieve, which is applied in the field of inorganic chemical synthesis, can solve the problems that the placement of heteroatoms is not explained, and the yield of aromatic hydrocarbons from alkane aromatization is not very high, and achieves good industrialization prospects, high crystallinity, and improved liquid crystallinity. The effect of receiving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

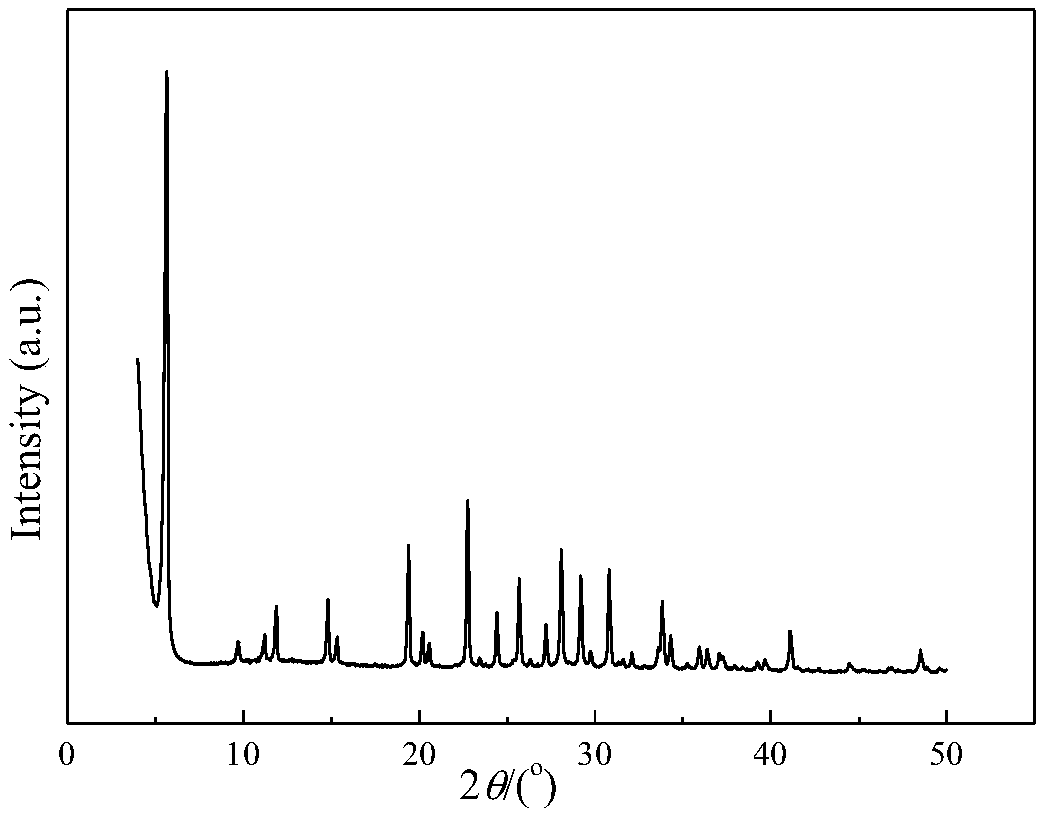

Embodiment 1

[0047] Add 100.3g KOH and 45.3g aluminum hydroxide to 1300g deionized water, stir evenly, transfer to a three-necked flask and react at 90°C for 12h, cool to room temperature to obtain clear KAlO 2 solution, K in the aluminum source solution 2 O: Al 2 o 3 The molar ratio is 2.56:1. In this solution, slowly add 668g silica sol (SiO 2 Content 30wt%), the initial sol was obtained after vigorous stirring. Take 12.85g Ce(NO 3 ) 3 ·6H 2O was dissolved in 200 g of deionized water to make a cerium source solution. The cerium source solution was slowly added dropwise into the sol and continued to stir vigorously, aged at 20°C for 5h, then transferred to a dynamic kettle, and reacted at 150°C for 48h. After crystallization, the reactant was cooled to room temperature, filtered, washed with deionized water until neutral, dried at 130°C for 6 hours, and calcined at 500°C for 4 hours to obtain Ce-containing LTL zeolite.

[0048] Among them, the amount of aluminum hydroxide is Al ...

Embodiment 2

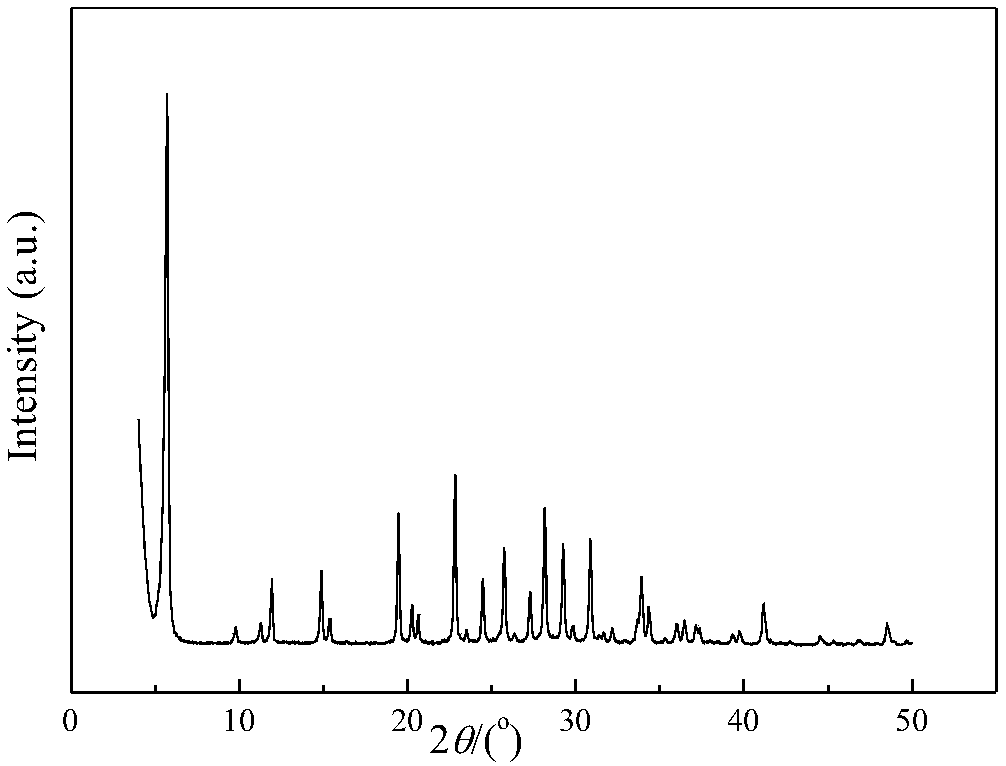

[0051] Add 100.3g KOH and 45.3g aluminum hydroxide to 1200g deionized water, stir evenly, transfer to a three-necked flask and react at 100°C for 24h, and get clear KAlO after cooling to room temperature 2 solution, K in the aluminum source solution 2 O: Al 2 o 3 The molar ratio is 2.56:1. In this solution, slowly add 668g silica sol (SiO 2 Content 30wt%), the initial sol was obtained after vigorous stirring. Take 64.25g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 300 g deionized water to make a cerium source solution. The cerium source solution was slowly added dropwise into the sol and continued to stir vigorously, aged at 20°C for 5h, then transferred to a dynamic kettle, and reacted at 180°C for 48h. After crystallization, the reactant was cooled to room temperature, filtered, washed with deionized water until neutral, dried at 100°C for 12 hours, and calcined at 450°C for 8 hours to obtain Ce-containing LTL zeolite.

[0052] Among them, the amount of aluminum hydroxide ...

Embodiment 3

[0055] Add 200.6g KOH and 45.3g aluminum hydroxide to 1100g deionized water, stir evenly, transfer to a three-necked flask, react at 90°C for 12h, cool to room temperature to obtain clear KAlO 2 solution, K in the aluminum source solution 2 O: Al 2 o 3 The molar ratio is 5.12:1. In this solution, slowly add 334g silica sol (SiO 2 Content 30wt%), the initial sol was obtained after vigorous stirring. Take 64.25g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 400 g of deionized water to make a cerium source solution. The cerium source solution was slowly added dropwise into the sol and continued to stir vigorously, aged at 20°C for 5h, then transferred to a dynamic kettle, and reacted at 150°C for 48h. After crystallization, the reactant was cooled to room temperature, filtered, washed with deionized water until neutral, dried at 85°C for 22 hours, and calcined at 580°C for 4 hours to obtain Ce-containing LTL zeolite.

[0056] Among them, the amount of aluminum hydroxide is Al 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com