A kind of fluorinated graphene lubricating oil additive, its preparation method and fluorinated graphene lubricating oil composite material

A lubricating oil additive, graphene lubricating oil technology, applied in additives, lubricating compositions, petroleum industry, etc., can solve the problems of insufficient fluorine repulsion, low interlayer spacing, hidden safety hazards, etc., achieve high utilization rate, increase interlayer spacing , the effect of expanding the layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

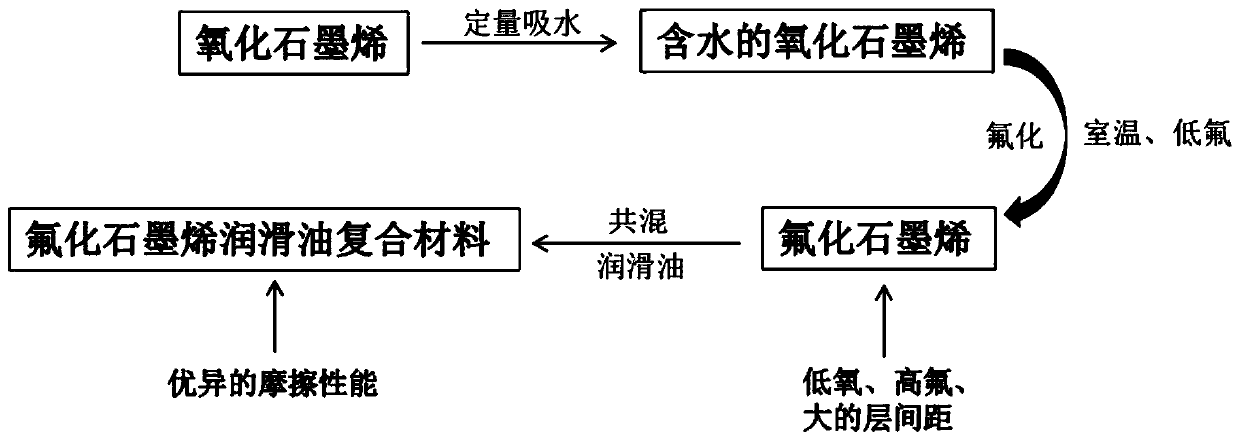

[0025] The preparation method of a kind of lubricating oil additive provided by the embodiment of the present invention, it comprises: After graphene oxide absorbs water, then carry out fluorination reaction, such as figure 1 shown in .

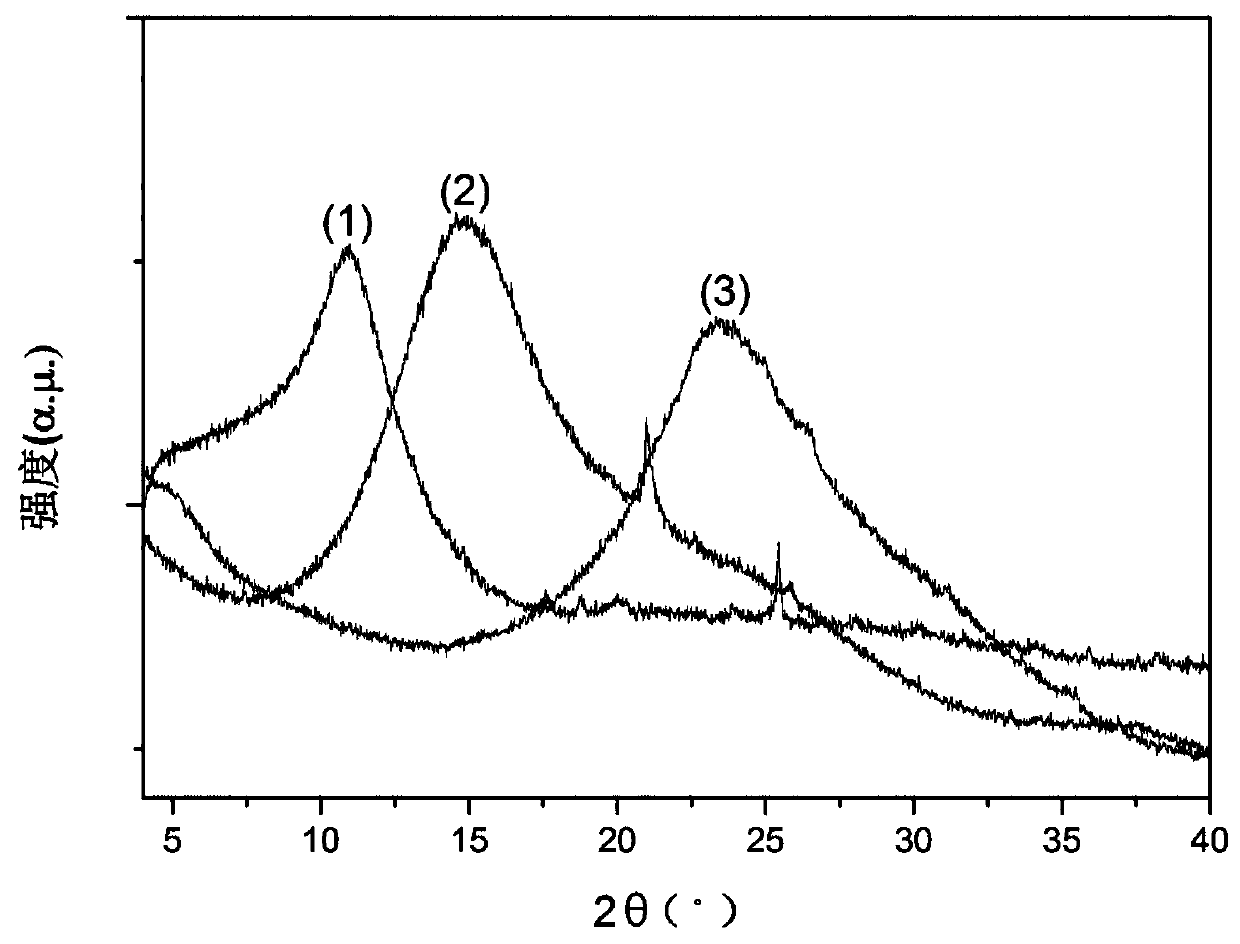

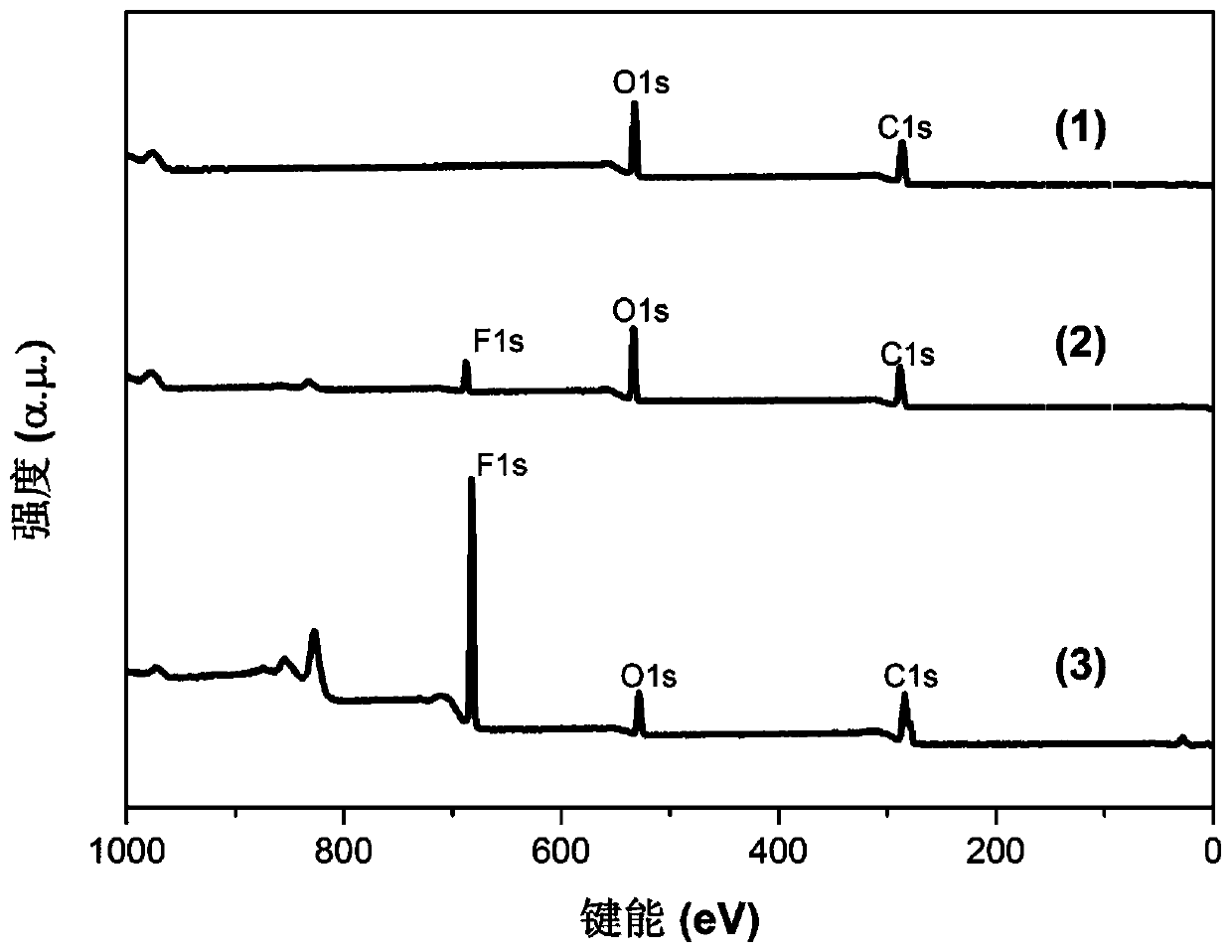

[0026] It should be noted that after using graphene oxide to absorb water, the water easily enters between the layers of graphene oxide and forms hydrogen bonds between the oxygen groups of graphene oxide, and at the same time increases the interlayer distance of graphene oxide, making fluorine gas It is easier to enter for fluorination; the fluorination process is carried out under normal temperature and low fluorine conditions, and the fluorine gas entering the interior of graphene oxide will react with the water medium preferentially, releasing a large amount of heat, which promotes the oxygen bonded with the water hydrogen bond The group breaks quickly, so that the in-situ fluorine gas and the HF generated by fluorine gas and water are gr...

Embodiment 1

[0045] This embodiment provides a kind of lubricating oil composite material, is made by following method:

[0046] First, 50 mg of graphene oxide was dried in a nitrogen atmosphere for 3 hours and then placed in a closed space containing water vapor for 1 hour to absorb moisture.

[0047] Secondly, the graphene oxide was transferred to the fluorination reaction kettle, nitrogen gas was introduced into the reaction kettle and the gas was pumped out until the pressure in the reaction kettle was lower than 100 Pa, and the above-mentioned nitrogen replacement was completed three times.

[0048] Then, feed the mixed gas of 5% fluorine and nitrogen into the reactor at a rate of 0.2 L / min until the pressure in the reactor reaches 2KPa, and react at room temperature for 30 minutes to complete the fluorination to obtain a high Fluorinated graphene with fluorine content.

[0049] Finally, 30 mg of fluorinated graphene was ultrasonically dispersed in 100 mL of liquid paraffin base lubr...

Embodiment 2

[0051] This embodiment provides a kind of lubricating oil composite material, is made by following method:

[0052] First, 50 mg of graphene oxide was dried in a nitrogen atmosphere for 3 hours and then placed in a closed space containing water vapor for 1 hour to absorb moisture.

[0053] Secondly, the graphene oxide was transferred to the fluorination reaction kettle, nitrogen gas was introduced into the reaction kettle and the gas was pumped out until the pressure in the reaction kettle was lower than 100 Pa, and the above-mentioned nitrogen replacement was completed three times.

[0054] Then, feed the mixed gas of 5% fluorine gas and nitrogen gas into the reactor at a rate of 0.2 L / min until the pressure in the reactor reaches 5KPa, and react at room temperature for 30 minutes to complete the fluorination, and obtain high Fluorinated graphene with fluorine content.

[0055] Finally, 30 mg of fluorinated graphene was ultrasonically dispersed in 100 mL of liquid paraffin b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com