Boron nitride/ Argentum/ carbon nanotube composite material and preparation method and purpose thereof

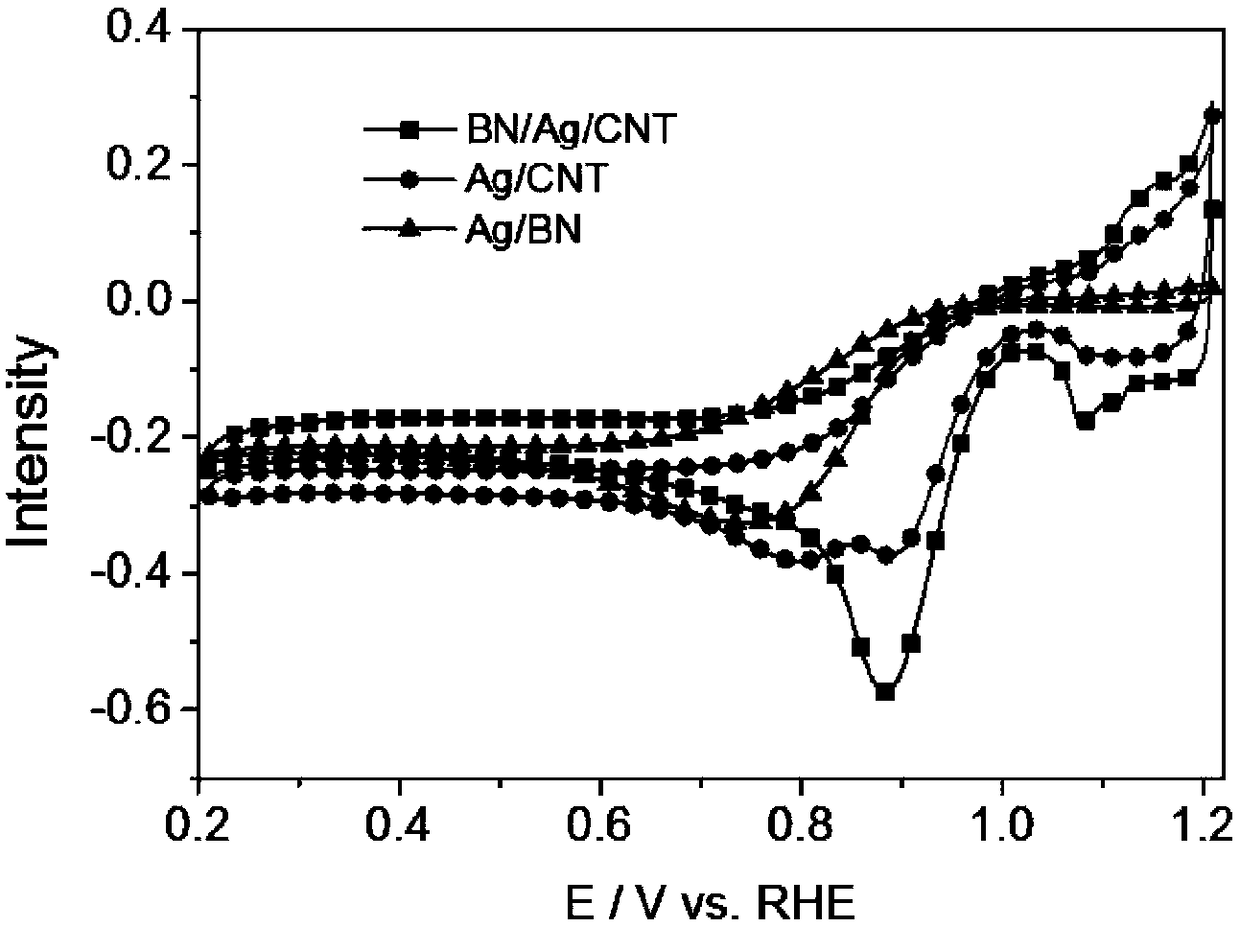

A composite material and immobilization technology, applied in the field of electrocatalytic materials, can solve problems such as few reports on electrochemical performance, and achieve the effects of high-efficiency electrocatalytic oxygen reduction performance, good electrochemical stability, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

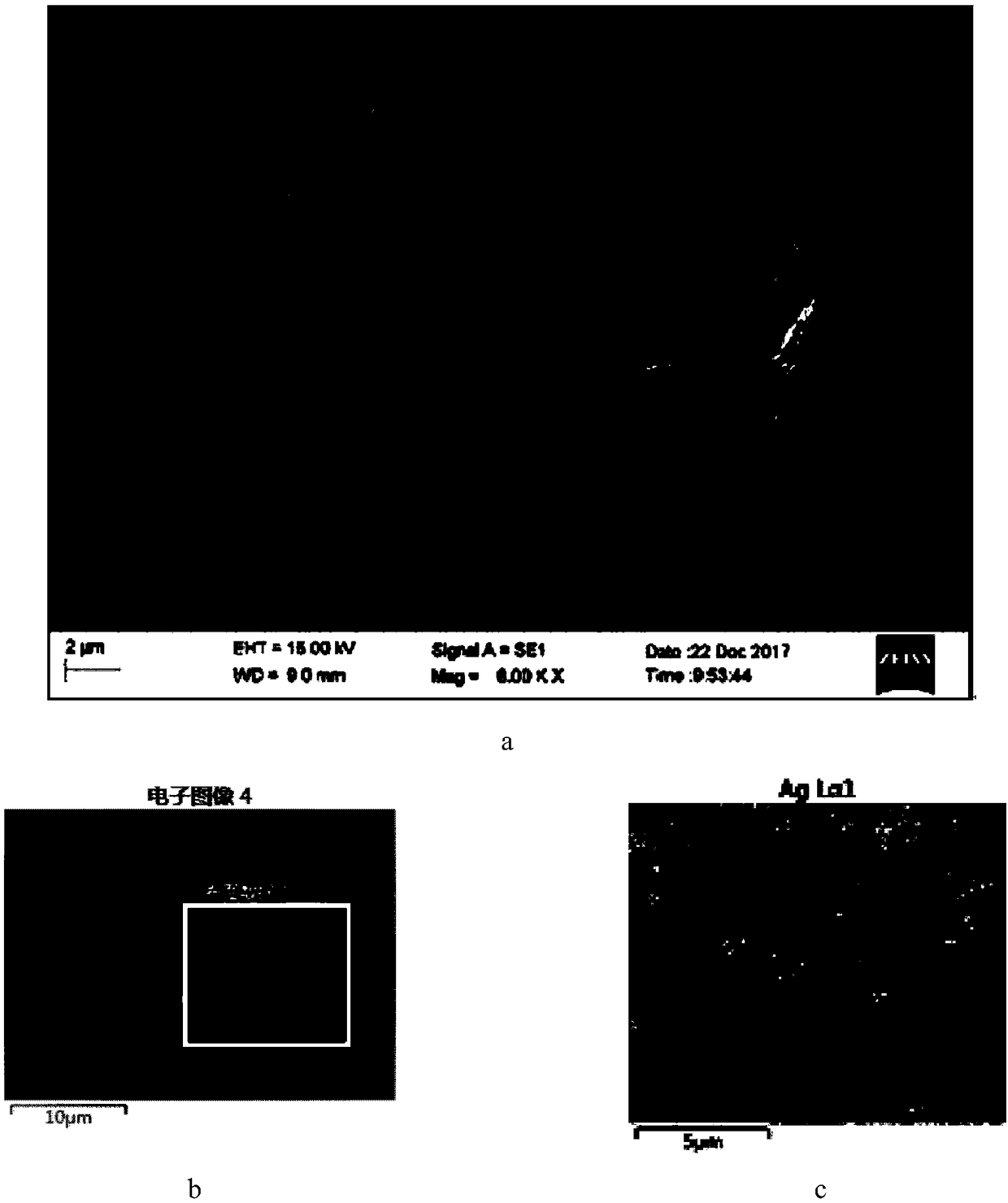

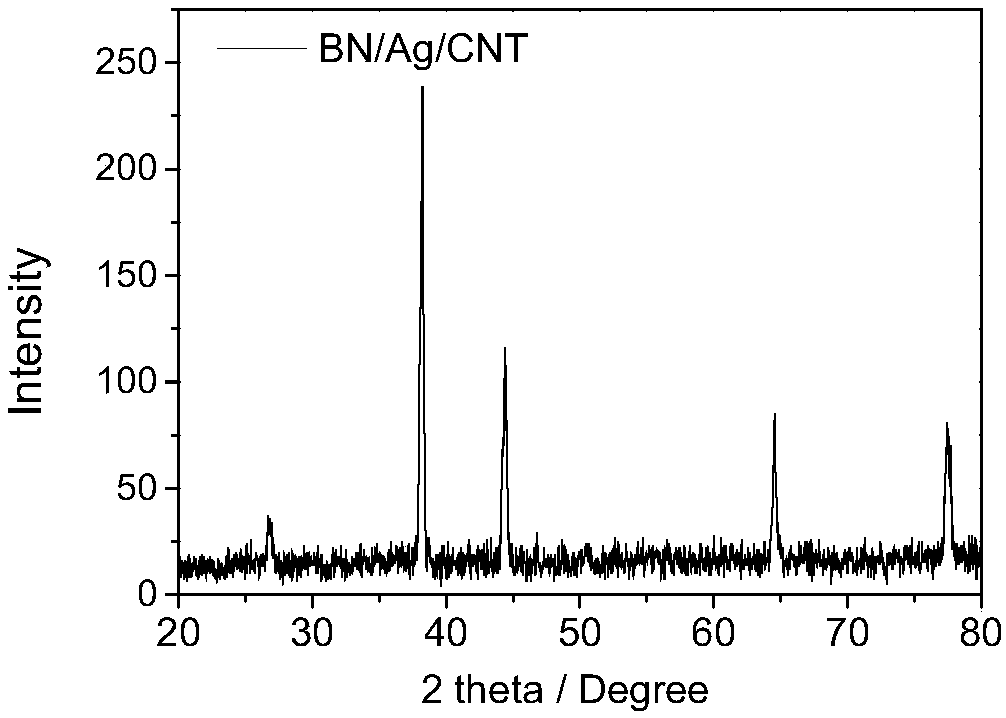

[0042] A BN / Ag / CNT composite material, metal Ag is evenly attached between BN sheets and on the surface of the sheets, and CNTs fix Ag and BN to form a cage structure. Among them, the molar ratio of BN, Ag and CNT is 1:2:1.

[0043] Its preparation method comprises the following steps:

[0044] (1) Add 30mL of deionized water into a 100mL small beaker, while stirring with a magnetic stirrer, add 1.6987g (0.01mol) of AgNO 3 , stirred until dissolved, a colorless uniform liquid was obtained, and concentrated ammonia water was slowly added dropwise until a precipitate was formed and then dissolved until the precipitate was dissolved to obtain a silver ammine ion solution;

[0045] (2) Add 2 mL of ethylene glycol, 0.06 g (0.005 mol) of carbon nanotubes, and 0.124 g (0.005 mol) of hexagonal boron nitride to the silver ammonium ion solution, stir for 2 min, and then sonicate for 30 min to make the mixture uniform;

[0046] (3) At room temperature, slowly add 30ml of 0.1mol / L sodiu...

Embodiment 2

[0051] The preparation method of the BN / Ag / CNT composite material in this example is the same as Example 1. The difference from Example 1 is that step (3) was vacuum-dried at 90° C. for 5 h, and after grinding, under an argon atmosphere, the Calcined at 850°C for 1.5h in a tube furnace.

Embodiment 3

[0053] The preparation method of the BN / Ag / CNT composite material in this example is the same as that of Example 1. The difference from Example 1 is that in step (3), vacuum drying was carried out at 80° C. for 6 h, and after grinding, under an argon atmosphere, the Calcined at 800°C for 3h in a tube furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com