Blocked isocyanate composition, prepolymer composition, method for producing these, and thermally dissociative blocking agent of blocked isocyanate composition

A technology of blocking isocyanate and isocyanate, which is applied in the field of blocked isocyanate composition, prepolymer composition and its manufacture, and as a thermal dissociative blocking agent of blocked isocyanate composition, can solve environmental impact, lack of Practicality, toxic sulfurous acid gas and other issues, to achieve the effect of inhibiting the emission of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

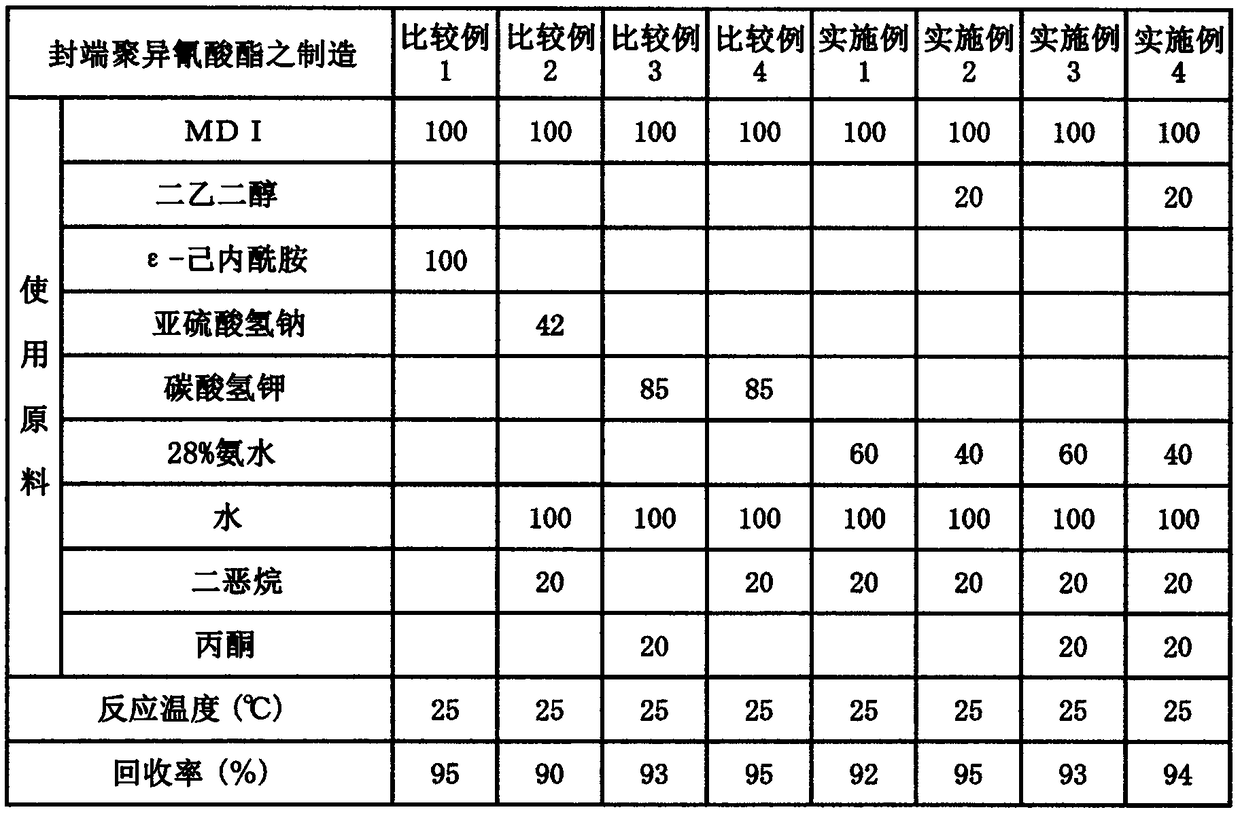

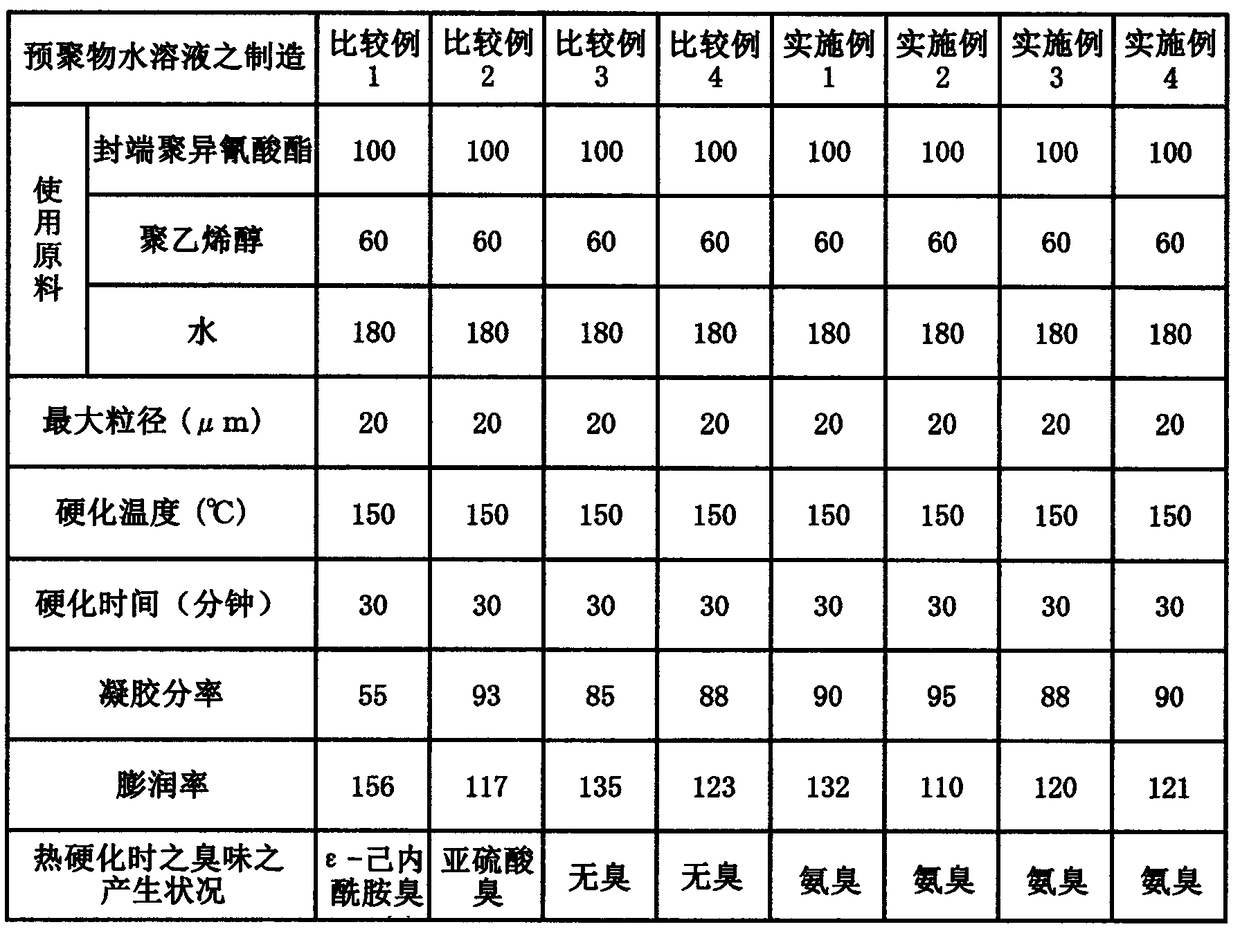

Embodiment 1

[0205] a) Step 1

[0206] First, put 60 parts of 28% ammonia water and 20 parts of dioxane (as an aprotic polar organic solvent) into a separable flask with a reflux condenser, and keep the temperature at 1000 rpm while stirring. 25°C.

[0207] b) Step 2

[0208] Next, in a separable flask, 100 parts of diphenylmethane diisocyanate (MDI) was slowly added over 1 hour to obtain a liquid blocked isocyanate solution at normal temperature (reaction temperature: 25° C.). The blocked isocyanate solution was vacuum-dried at 60° C. to obtain a solid blocked isocyanate (blocked isocyanate of Example 1). The recovery rate of the blocked isocyanate of Example 1 was 92%.

[0209] c) Step 3

[0210] Next, 100 parts of the blocked isocyanate of Example 1 were dispersed and mixed in an aqueous solution obtained by adding a 25% polyvinyl alcohol aqueous solution so that the solid content ratio became 60 parts (that is, as shown in the table of FIG. 2 ). , mixed 100 parts of blocked isocya...

Embodiment 2

[0213] a) Step 1

[0214] First, 40 parts of 28% ammonia water and 20 parts of dioxane (as an aprotic polar organic solvent) were placed in a separable flask with a reflux condenser, and the temperature was maintained at 1000 rpm while stirring at 1000 rpm. 25°C.

[0215] b) Step 2

[0216] Next, in a separable flask, 100 parts of diphenylmethane diisocyanate (MDI) was slowly added over 1 hour to obtain a liquid blocked isocyanate solution at normal temperature (reaction temperature: 25° C.). The blocked isocyanate solution was vacuum-dried at 60° C. to obtain a solid blocked isocyanate (blocked isocyanate of Example 2). The recovery rate of the blocked isocyanate of Example 2 was 95%.

[0217] c) Step 3

[0218] Next, 100 parts of blocked isocyanate was dispersed and mixed in an aqueous solution obtained by adding a 25% polyvinyl alcohol aqueous solution so that the solid content ratio became 60 parts (that is, as shown in the table of FIG. Mix 100 parts of blocked isocy...

Embodiment 3

[0220] a) Step 1

[0221] First, in a separable flask with a reflux condenser, 60 parts of 28% ammonia water, 20 parts of dioxane (as an aprotic polar organic solvent) and 20 parts of acetone (amphiphilic) were placed. Stirring was performed at 1000 rpm while maintaining the temperature at 25°C.

[0222] b) Step 2

[0223] Next, in a separable flask, 100 parts of diphenylmethane diisocyanate (MDI) was slowly added over 1 hour to obtain a liquid blocked isocyanate solution at normal temperature (reaction temperature: 25° C.). The blocked isocyanate solution was vacuum-dried at 60° C. to obtain a solid blocked isocyanate (blocked isocyanate of Example 3). The recovery rate of the blocked isocyanate of Example 3 was 93%.

[0224] c) Step 3

[0225]Next, 100 parts of blocked isocyanate was dispersed and mixed in an aqueous solution obtained by adding a 25% polyvinyl alcohol aqueous solution so that the solid content ratio became 60 parts (that is, as shown in the table of FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com