My/LaxSr(1-x)Ti(1-y)O3 catalyst as well as preparation method and application thereof

A catalyst and compound technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of unsatisfactory catalytic results and internal diffusion of doped noble metal surface precipitation Serious impact, disordered and uneven pores, etc., to achieve the effects of adjustable product structure and composition, reduced catalyst cost, and low content of noble metal active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Another aspect of the embodiment of the present invention also provides a M y / La x Sr 1-x Ti 1-y o 3 The preparation method of catalyst, it comprises:

[0038] The mixed metal precursor system is mixed with the hard template microspheres and calcined at high temperature to obtain a three-dimensional ordered mesoporous perovskite structure noble metal-doped La x Sr 1-x Ti 1-y m y o 3 A catalyst precursor, wherein x is 0.05 to 0.95, y is 0.01 to 0.1, and M is a noble metal doping active component, wherein the value of y ensures that the noble metal doping active component M is less than or equal to the saturation doping amount, and the metal precursor The mixed compound system includes the combination of La-containing compound, Sr-containing compound, Ti-containing compound and noble metal precursor;

[0039] Carry out reduction treatment to described catalyst precursor in reducing atmosphere, make M y / La x Sr 1-x Ti 1-y o 3 A catalyst, wherein the catalys...

Embodiment 1

[0071] A kind of 2.77wt%Pd that present embodiment relates to 0.05 / La 0.1 Sr 0.9 Ti 0.95 o 3 The preparation technology of catalyst comprises the steps:

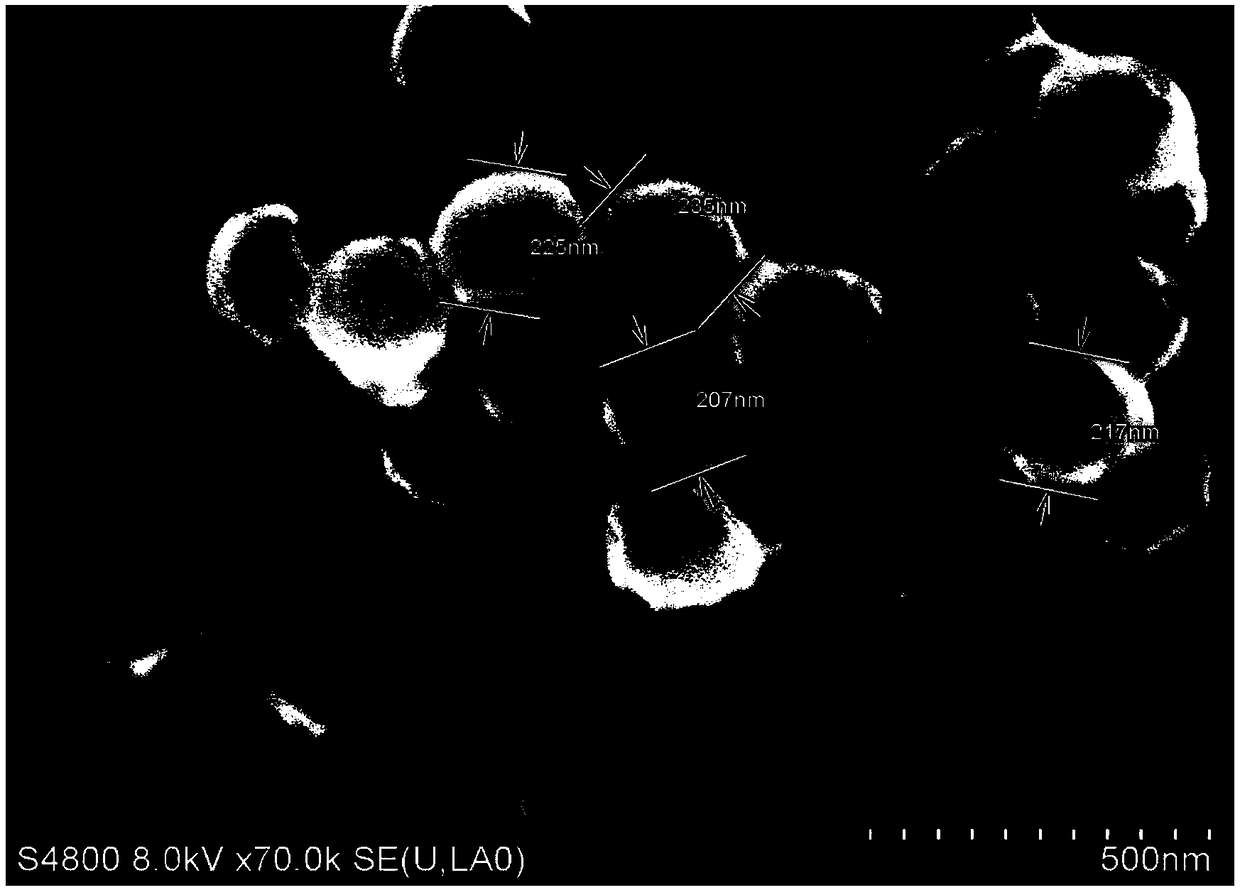

[0072] (1) Preparation of PMMA hard sphere templates with a size of about 200nm

[0073] Add 650ml deionized water into a 1000ml three-neck flask, 2 Under the atmosphere, with 350rpm and 70 ℃ of continuous bubbling stirring, after 30 minutes, add 55 mg of methyl methacrylate (PMMA) solution mixed with 0.03% p-hydroxybenzoic acid, after heating at 70 ℃ for 15 minutes, add potassium persulfate to trigger agent solution, heated and stirred for 40 minutes, centrifuged and dried to obtain a PMMA hard sphere template with a size of about 200nm, see figure 2 shown.

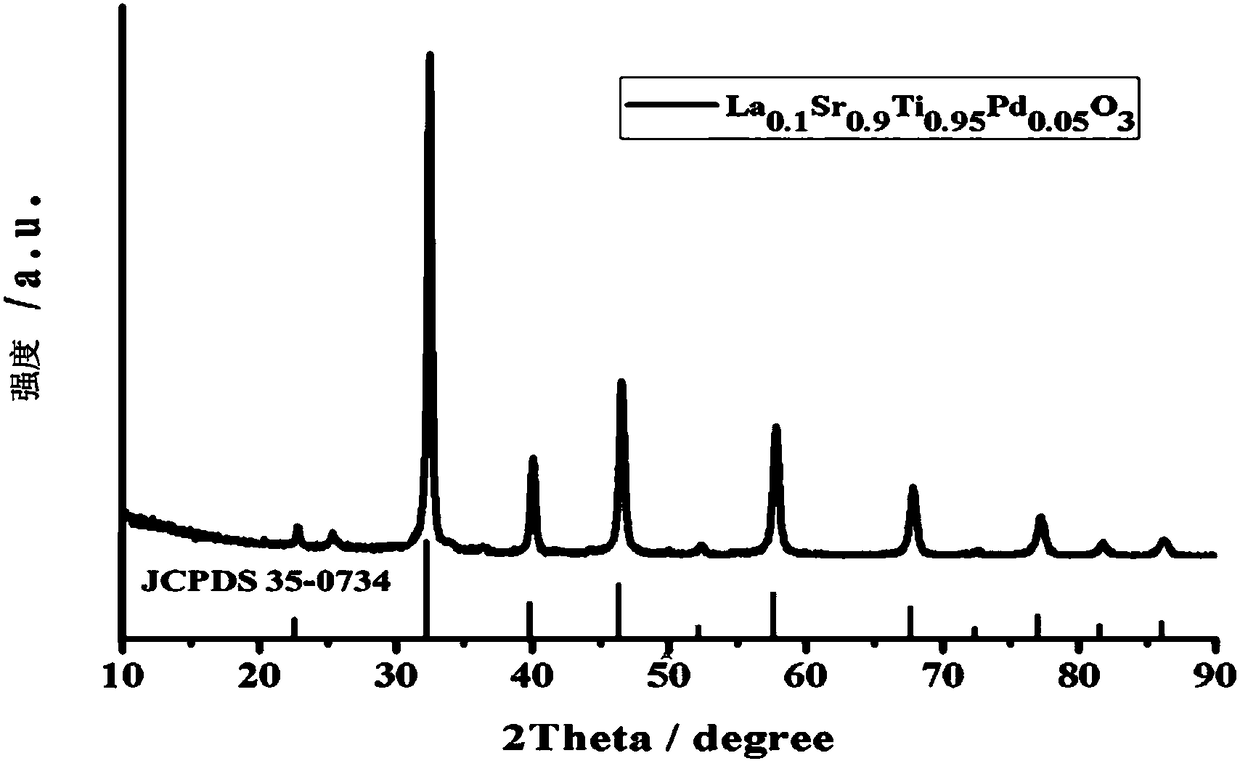

[0074] (2) Three-dimensional ordered mesoporous perovskite structure La 0.1 Sr 0.9 Ti 0.95 PD 0.05 o 3 Synthesis of vector

[0075] 0.4330g La(NO 3 ) 3 ·6H 2 O, 1.9047g Sr(NO 3 ) 2 , 3.23g Ti(OC 4 h 9 ) 4 , 0.3547gPd(NO 3 ) 2 The nitrate mixtur...

Embodiment 2

[0089] A kind of 0.457wt%Pd that present embodiment relates to 0.01 / La 0.95 Sr 0.05 Ti 0.99 o 3 The preparation technology of catalyst comprises the steps:

[0090] (1) Preparation of PMMA hard sphere templates with a size of about 300nm

[0091] Add 650ml deionized water into a 1000ml three-neck flask, 2 Under the atmosphere, with 350rpm and 70 ℃ of continuous bubbling stirring, after 30 minutes, add 55 mg of methyl methacrylate (PMMA) solution mixed with 0.03% p-hydroxybenzoic acid, after heating at 70 ℃ for 15 minutes, add potassium persulfate to trigger agent solution, heated and stirred for 40 minutes, centrifuged and dried to obtain a PMMA hard sphere template with a size of about 300nm, see figure 2 shown.

[0092] (2) Three-dimensional ordered mesoporous perovskite structure La 0.95 Sr 0.05 Ti 0.99 PD 0.01 o 3 Synthesis of vector

[0093] 4.1135g La(NO 3 ) 3 ·6H 2 O, 0.1058g Sr(NO 3 ) 2 , 3.37g Ti(OC 4 h 9 ) 4 , 0.07gPd(NO 3 ) 2 The nitrate mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com