Gasoline vehicle particle filter catalyst and preparation method thereof

A particle trap and catalyst technology, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problems of high exhaust back pressure and low exhaust back pressure, and achieve back Reduce pressure drop, improve rheology, and inhibit the effect of high temperature sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

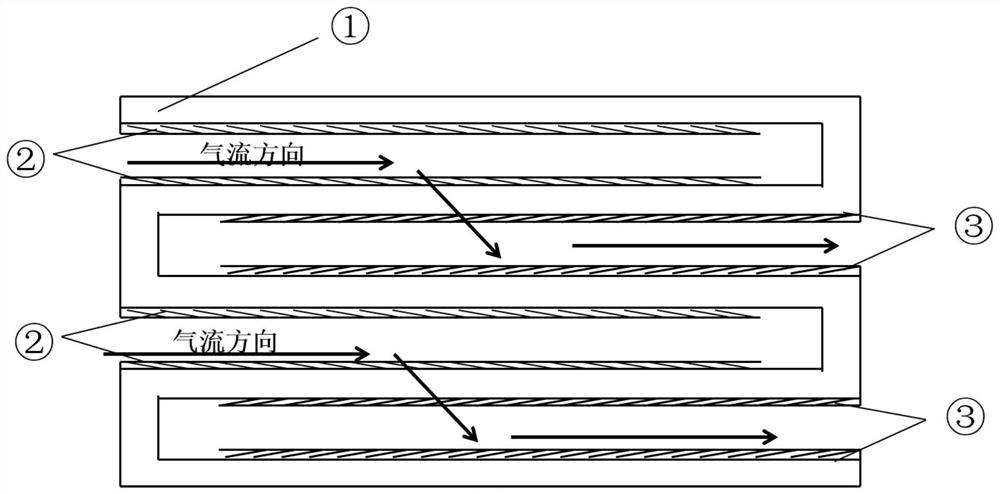

[0030] A wall-flow honeycomb ceramic carrier with a specification of Φ118.4mm*127mm, a mesh number of 300 mesh, a pore wall thickness of 203.2μm, a porosity of 65%, an average pore diameter of 20μm and a volume of 1.398L was selected.

[0031] First coat the first coating 2 on one end of the carrier 1, the coating amount of the first coating 2 is 60g / L, the height of the coating along the axial direction is 90% of the height of the carrier, and the loading amount of Rh is 3g / ft 3 . The other end of the carrier 1 is coated with the second coating 3, the coating amount of the second coating 3 is 60g / L, the height of the coating along the axial direction is 90% of the height of the carrier 1, and the loading of Pd is 4g / L. ft 3 .

[0032] The composition of the cerium-zirconium rare earth composite oxide used in the coating is calculated by mass percentage: 20% CeO 2 , 75% ZrO 2 , 1% La 2 o 3 and 4% Pr 6 o 11 . The components in the lanthanum-aluminum composite oxide use...

Embodiment 2

[0045] A wall-flow honeycomb ceramic carrier 1 with a specification of Φ118.4mm*127mm, a mesh number of 300 mesh, a pore wall thickness of 203.2μm, a porosity of 65%, an average pore diameter of 20μm and a volume of 1.398L was selected. First coat the first coating 2 at one end of the carrier 1, the coating amount of the first coating 2 is 30g / L, the height of the coating along the axial direction is 50% of the height of the carrier 1, and the loading of Rh is 10g / L. ft 3 . Coating the second coating 3 on the other end of the support, the coating amount of the second coating 3 is 30g / L, the height of the coating along the axial direction is 50% of the height of the support, and the loading of Pd is 20g / ft 3 .

[0046] The composition of the cerium-zirconium rare earth composite oxide used in the coating is calculated by mass percentage: 30% CeO 2 , 65% ZrO 2 , 2% La 2 o 3 and 3% Nd 2 o 3 . The components in the lanthanum-aluminum composite oxide used in the coating ar...

Embodiment 3

[0059] A wall-flow honeycomb ceramic carrier 1 with a specification of Φ118.4mm*127mm, a mesh number of 300 mesh, a pore wall thickness of 203.2μm, a porosity of 65%, an average pore diameter of 20μm and a volume of 1.398L was selected. First coat the first coating 2 on one end of the carrier 1, the coating amount of the first coating 2 is 50g / L, the height of the coating along the axial direction is 75% of the height of the carrier 1, and the loading of Rh is 6g / L. ft 3 . Coating the second coating 3 on the other end of the carrier 1, the coating amount of the second coating 3 is 50g / L, the height of the coating along the axial direction is 75% of the height of the carrier, and the loading amount of Pd is 8g / ft 3 .

[0060] The composition of the cerium-zirconium rare earth composite oxide used in the coating is calculated by mass percentage: 25% CeO 2 , 68% ZrO 2 , 1% La 2 o 3 and 6% of Y 2 o 2 . The components in the lanthanum-aluminum composite oxide used in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com