Water-soluble inlaid thorium fullerene and preparation method and application thereof

A fullerene and water-soluble technology, applied in the field of material chemistry, can solve the problems of difficult scale-up of preparation and low yield of embedded fullerene, and achieve high yield, simple production process and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

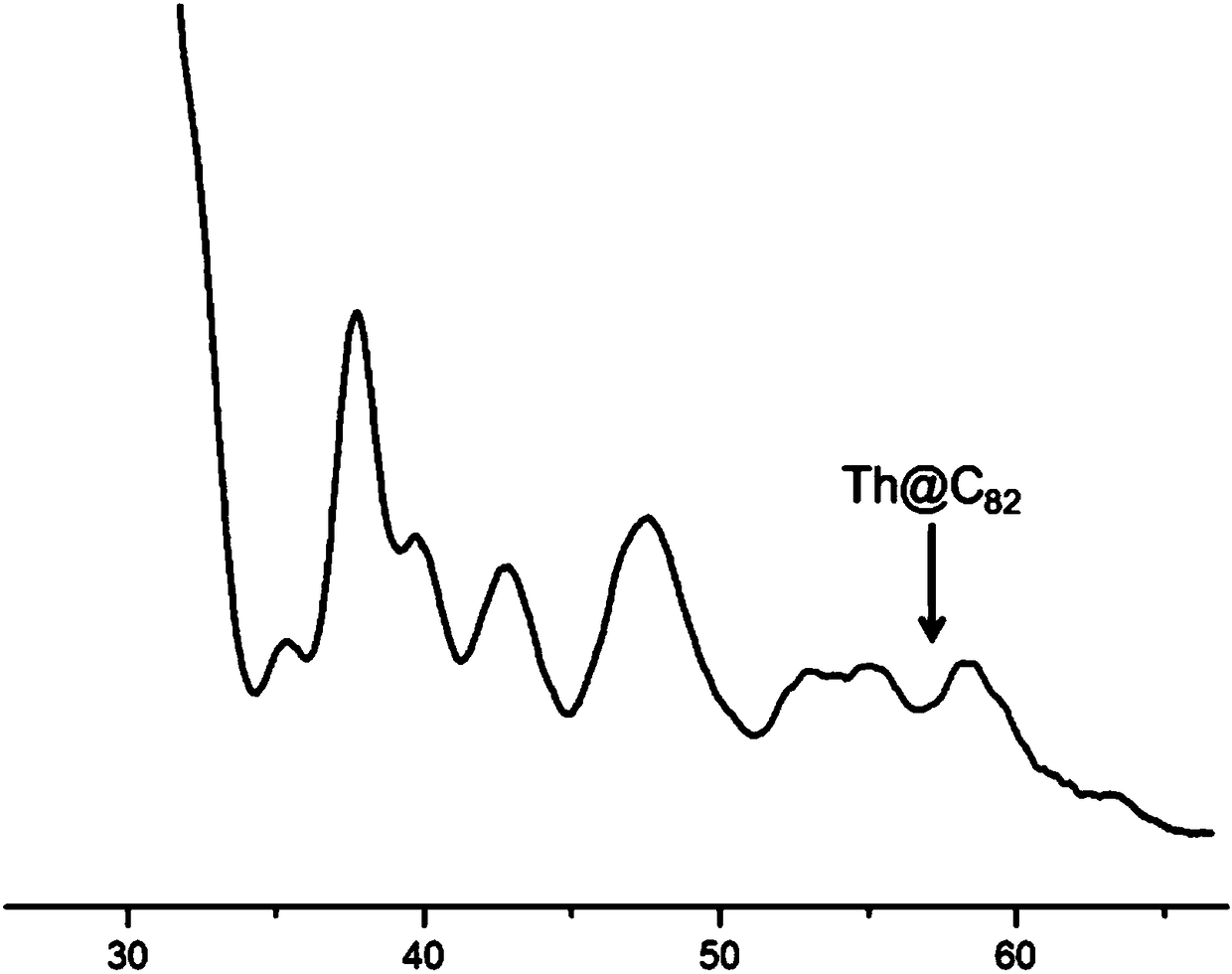

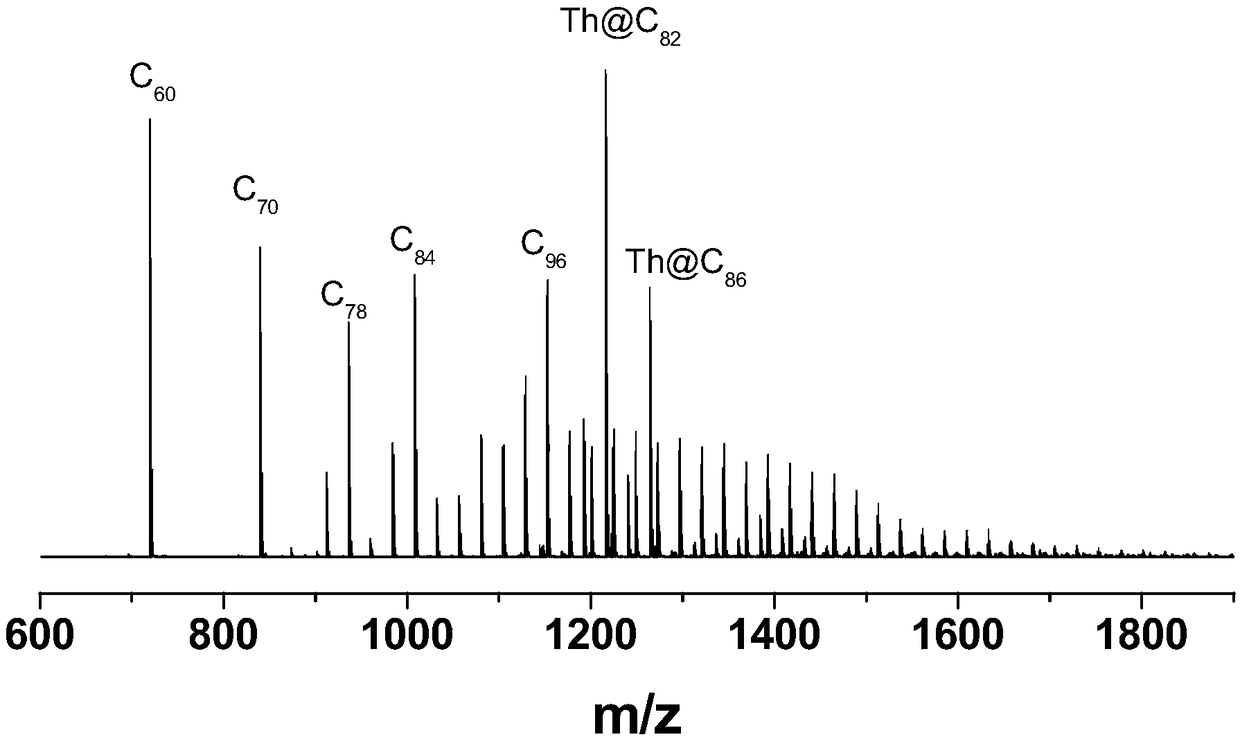

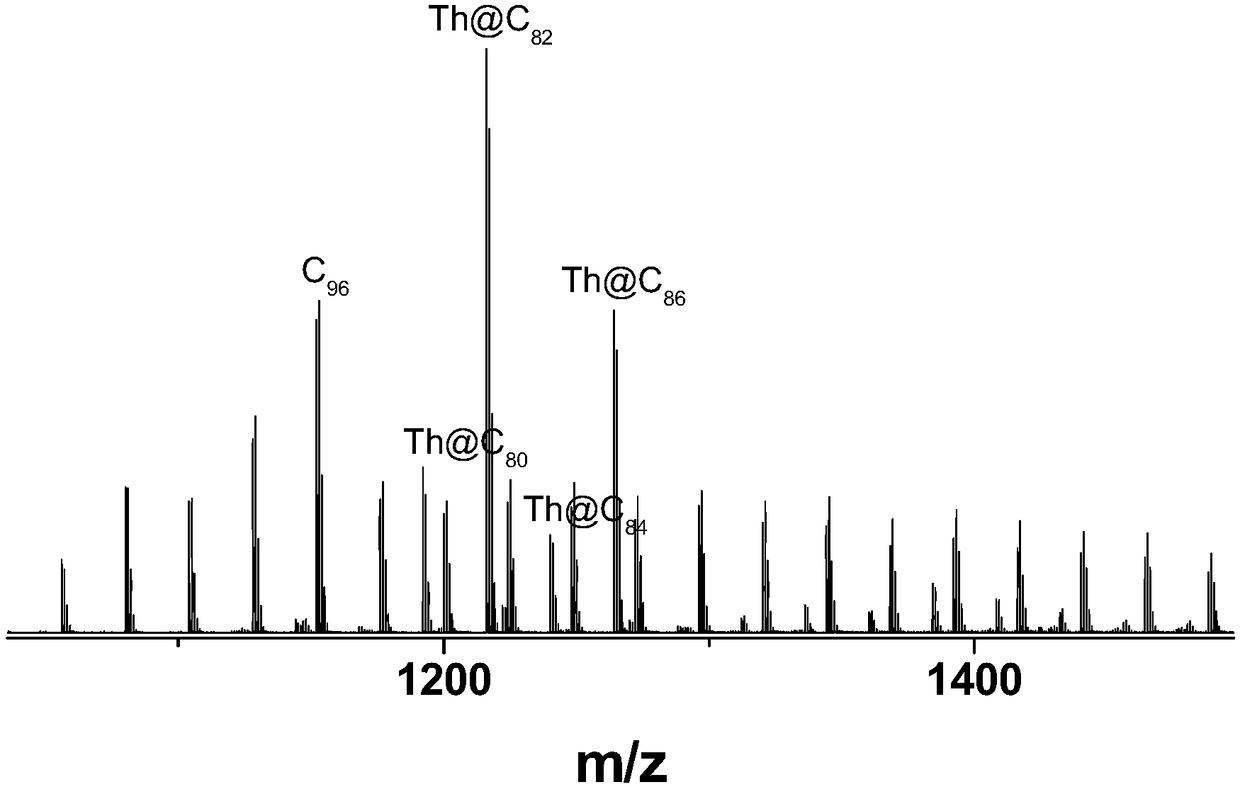

Method used

Image

Examples

Embodiment 1

[0047](1) Preparation of fullerene: Drill a solid spectrally pure graphite rod with a diameter of 8 mm and a length of 100 mm into a hollow graphite rod with an inner diameter of 6 mm and a depth of about 80 mm. ThO 2 The mixture of graphite and graphite powder (molar ratio 1:24) was filled into the above-mentioned hollow graphite rod and compacted. The filled graphite rods were placed in a high-temperature tube furnace and heated to 1000 °C under a high-purity Ar atmosphere, and kept for 10 hours to serve as anodes. A solid spectrally pure graphite rod serves as the cathode.

[0048] Install the pretreated graphite rod on the anode of the vacuum electric arc furnace and fix it, seal the furnace cavity, turn on the vacuum pump, pump the furnace cavity to a pressure lower than 10 Pa, turn off the vacuum pump, and fill the furnace cavity with high-purity He gas , the air pressure in the furnace chamber is about 2.95×10 4 Pa. Turn on the circulating cooling water, turn on th...

Embodiment 2

[0056] Filter the solution obtained in step (4) of Example 1 with a 0.45um filter membrane, distill it under reduced pressure to 1mL, add water-soluble ethanol, a poor solvent embedded with thorium fullerene, and precipitate a yellow precipitate, collect it by centrifugation and wash it three times with ethanol , and then the solid was dissolved in deionized water and dialyzed with a dialysis bag with a molecular weight cut off of 3500 to obtain a contrast agent based on water-soluble thorium fullerene embedded. Finally, the obtained water-soluble contrast agent embedded with thorium fullerene is used for CT imaging, and its performance is better than that of iodofluhydrin, see Figure 8 , the first row is the CT imaging image of iodofluhydrin, and the second row is the CT imaging image of the contrast agent based on water-soluble embedded thorium fullerene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com