Biological denitrification method of refuse leachate

A technology for landfill leachate and biological denitrification, which is applied in the field of landfill leachate biological denitrification and waste incineration plant leachate biological denitrification, can solve the problems of large output of excess sludge, long residence time, and high capital investment costs, and achieves The effect of reducing excess sludge production and construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

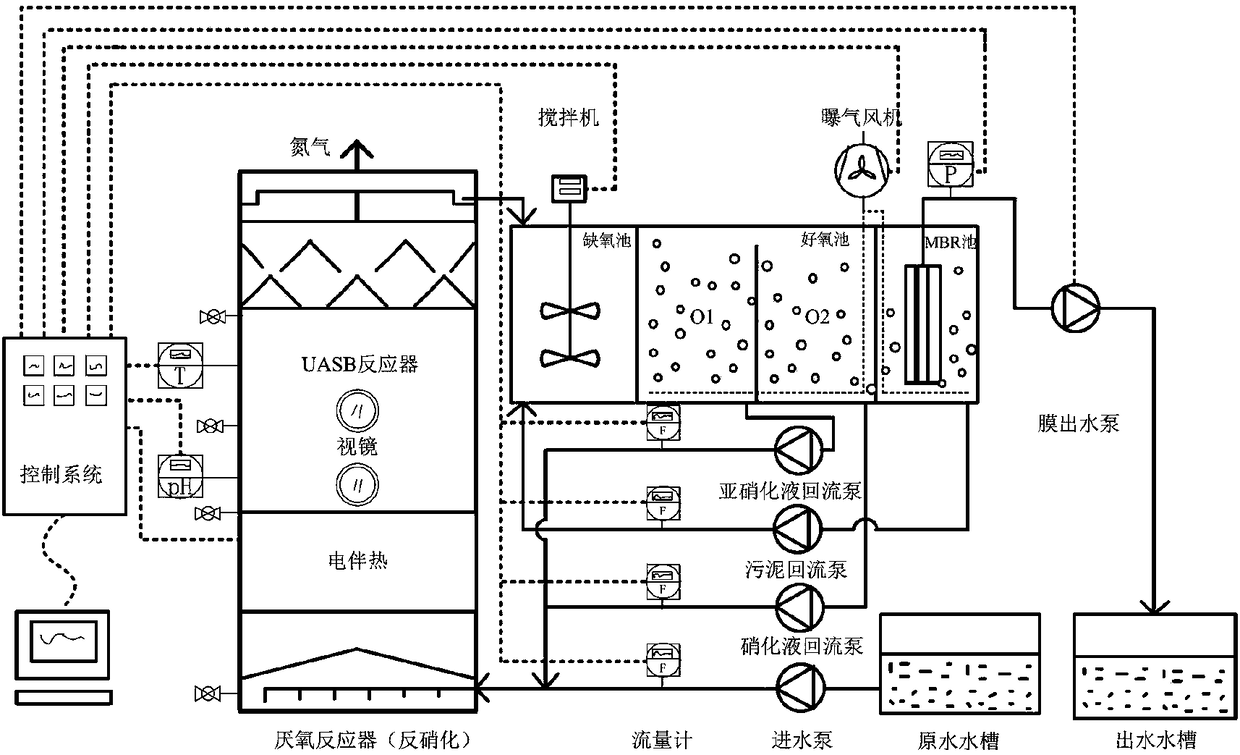

Method used

Image

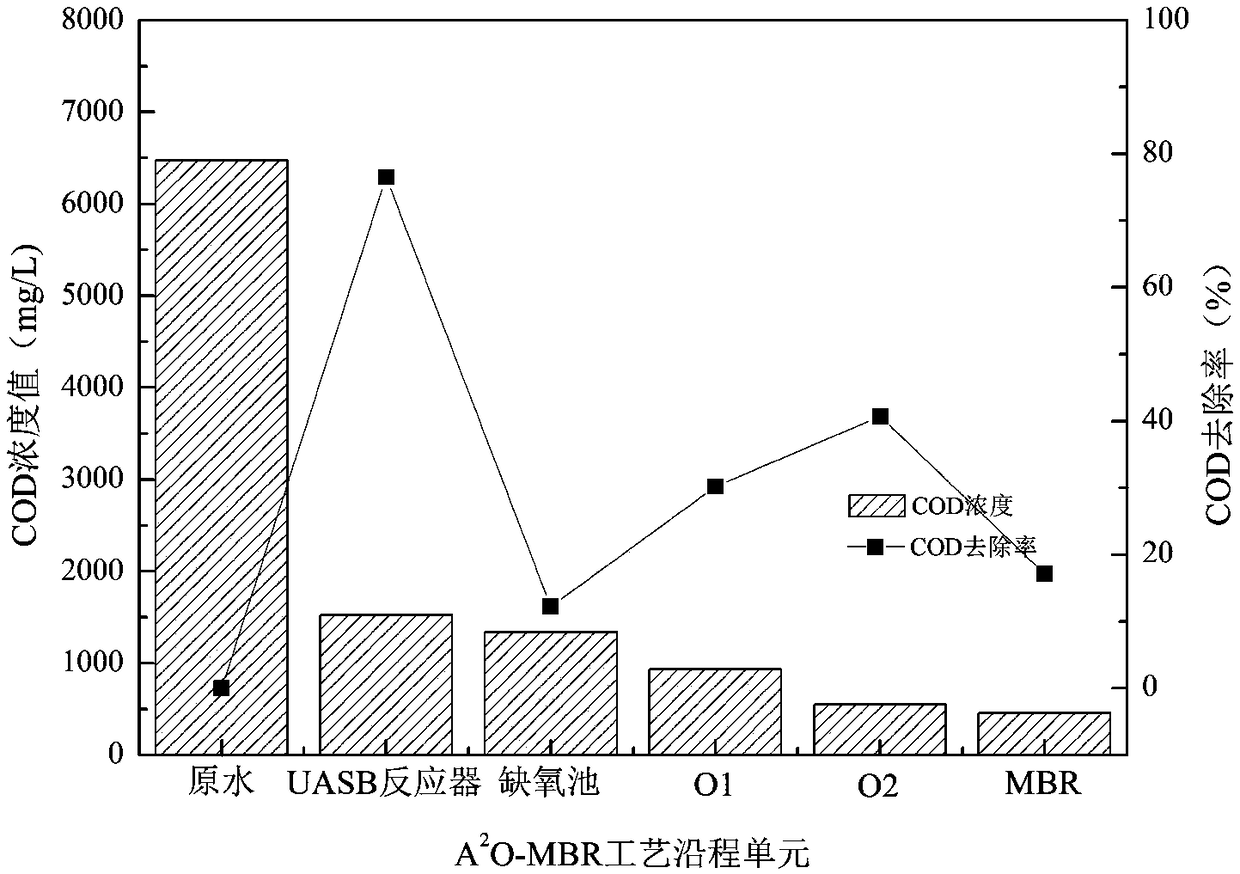

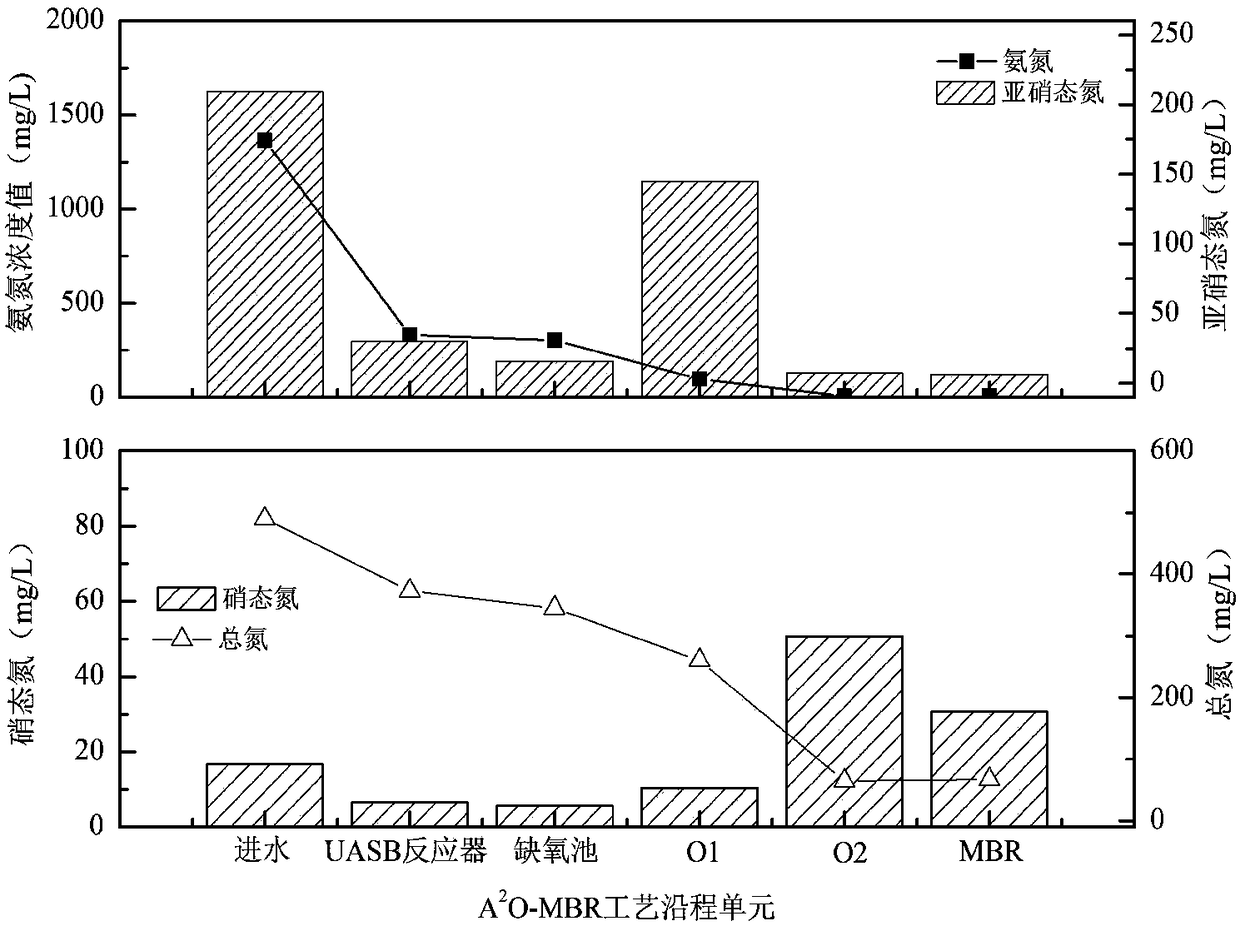

Examples

Embodiment 1

[0021] The process inoculation sludge is taken from the nitrification sludge in the AO aerobic pool of the sewage treatment plant, and is inoculated in each unit of the process after dehydration by pressure filtration. The concentration ratio of total suspended solids (TSS) and volatile suspended solids (VSS) in the inoculation sludge If it is lower than 0.6, the amount of inoculated sludge shall be 5kgTSS / m 3 Dosing.

[0022] After the inoculation is completed, start the operation with continuous water inflow, control the hydraulic retention time to 6d, the temperature of the aerobic tank to 25-35°C, the sludge age to 15-20d, and the influent ammonia nitrogen load to 0.1-0.35kg NH 4 + -N / (m 3 d) Control the sludge concentration in the aerobic tank to 8-12g / L through the interception of the MBR membrane and the sludge return in the MBR tank, the dissolved oxygen concentration in the anoxic tank is 0.2-0.5mg / L, O1 and O2 in the aerobic tank The concentration of dissolved oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com