Technology for treating waste liquid of dacromet

A waste liquid treatment, dacromet technology, applied in filtration treatment, water/sewage treatment, reductive water/sewage treatment, etc., can solve the problem of low pollution, achieve high recycling rate, obvious energy saving and emission reduction, treatment low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

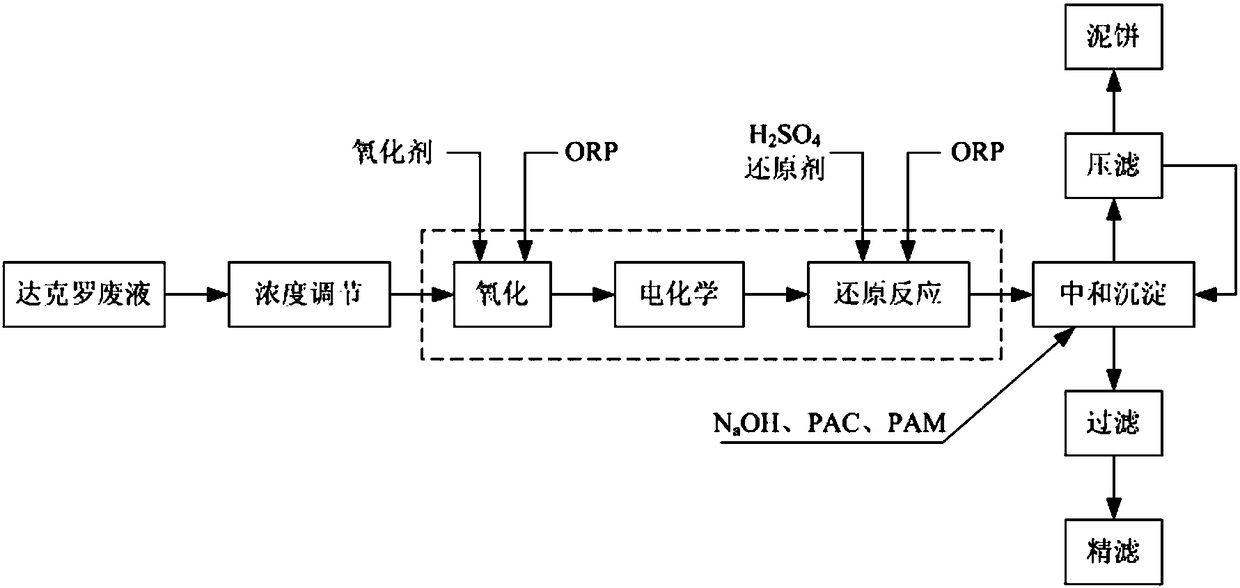

[0052] A process for treating waste liquid of Dacromet paint, comprising the following steps:

[0053] Step 1, concentration adjustment: the dacromet waste liquid is passed through the concentration adjustment step, and the concentration of the dacromet waste liquid is adjusted to a concentration range convenient for redox reaction.

[0054] The concentration of the dacromet waste liquid adjusted in the first step is 10-15%.

[0055] Step 2, oxidation-reduction: the adjusted dacromet waste liquid in step 1 undergoes oxidation, electrochemical and reduction reactions in sequence, and the dacromet waste liquid is separated into layers.

[0056] The redox process described in step 2 specifically includes the following steps:

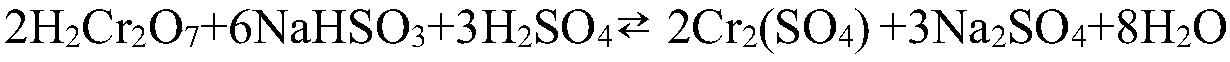

[0057] ⑴ Oxidation: ORP oxidation-reduction potentiometer is used in the treatment of wastewater to transfer heavy metals to Z under automatic control. n 2+ 、C r 6+ , Metal Al 3+ Add oxidant to Dacromet wastewater such as various fiber materials to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com