Degradable biological thin film and preparation method thereof

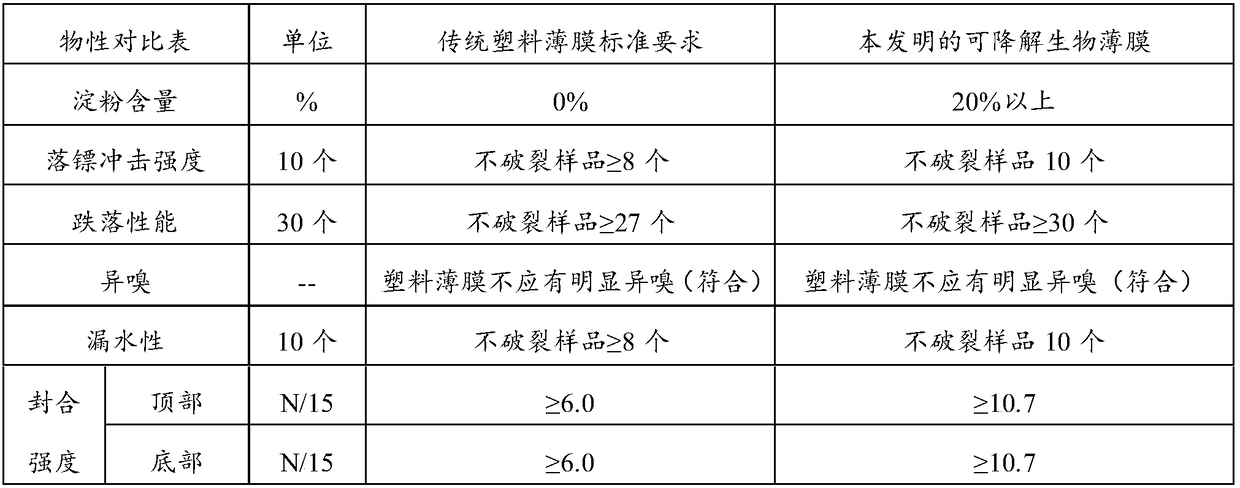

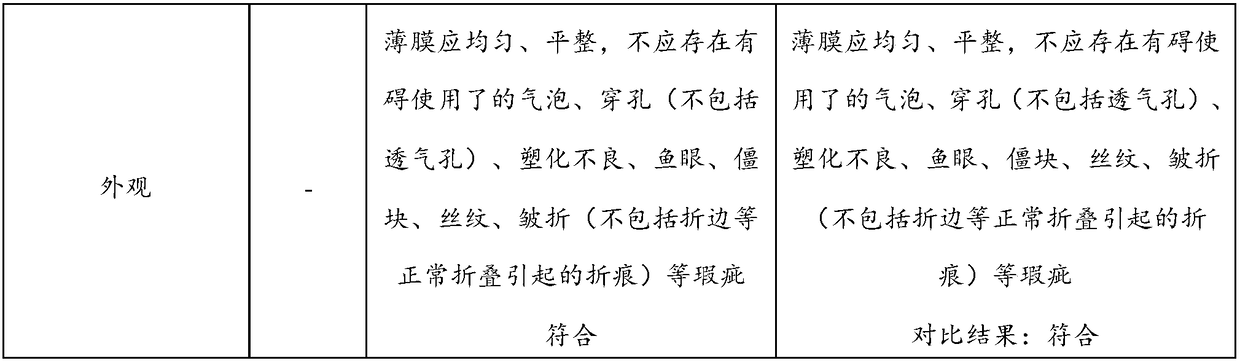

A biofilm and film technology, applied in the field of degradable biofilm and its preparation, can solve the problems that cannot be widely applied and promoted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046]The present invention also provides a method for preparing the above biodegradable biofilm, comprising: extruding and blowing the inner layer film raw material, the middle layer film raw material and the outer layer film raw material through a three-layer co-extrusion blown film machine, and cooling to obtain Degradable biological film; the outer layer film is formed by 50-75 parts by weight of the first polymer, 15-20 parts by weight of the first modified starch and 10-17 parts by weight of the first additive; the middle layer film It is formed by 45-65 parts by weight of the second polymer, 20-30 parts by weight of the second modified starch and 10-17 parts by weight of the second additive; the inner film is composed of 50-70 parts by weight of the third polymer 15-25 parts by weight of the third modified starch and 10-17 parts by weight of the third additive; and the material composition ratio of the outer layer film and the middle layer film is different; the first po...

Embodiment 1

[0054] The raw material of the outer layer film: modified starch content is 15%; polylactic acid 15%; polybutylene oxalate terephthalate 13%; ethylene-acrylic acid copolymer 30%; polyethylene medium density FB#2230 / 231010%; talcum powder 5%; chain extender 1.3%; erucamide 0.4%; zinc stearate 0.35%; melt strength enhancer 0.3%; anti-hydrolysis stabilizer 1.5%; Wax 0.65%.

[0055] The raw material of the middle layer film: modified corn starch content 25%; Jinan Daigang Biotechnology Co., Ltd. polylactic acid 10%; Shenzhen Huibaotong Industrial Co., Ltd. polybutylene oxalate terephthalate 13%; Hangzhou Shengou Plastic Chemical Co., Ltd. ethylene-acrylic acid copolymer 25%; Borealis polyethylene medium density FB#2230 / 2310 10%; talcum powder 5%; Zhangjiagang Yarui Chemical Co., Ltd. chain extender 1.3%; Hubei Xinhe Raw Materials Co., Ltd. Responsible company erucamide 0.4%; Yangzhou Linghang Chemical Co., Ltd. zinc stearate 0.35%; Xinjiang Lanshan melt strength enhancer 0.3%; Q...

Embodiment 2

[0065] Raw materials for the outer film: 20% modified corn starch; 13% polylactic acid from Jinan Daigang Biotechnology Co., Ltd.; 10% polybutylene terephthalate from Shenzhen Huibaotong Industrial Co., Ltd.; Hangzhou Shengou Plastic Chemical Co., Ltd. ethylene-acrylic acid copolymer 30%; Borealis polyethylene medium density FB#2230 / 2310 10%; talcum powder 5%; Zhangjiagang Yarui Chemical Co., Ltd. chain extender 1.3%; Hubei Xinhe Raw Materials Co., Ltd. The company's erucamide 0.4%; Yangzhou Linghang Chemical Co., Ltd. zinc stearate 0.35%; Xinjiang Lanshan melt strength enhancer 0.3%; Qingdao Changrong Chemical's environmental protection anti-hydrolysis stabilizer 1.5%; Penglai Sanyou DIDF-40 Anti-ultraviolet additive 7.5%; PE wax 0.65% of Xinkehong Plastic Factory in Nan'an City, Fujian Province. .

[0066] The raw material of the middle layer film: 25% of modified cornstarch content; preferably 10% of polylactic acid of Jinan Daigang Biotechnology Co., Ltd; 13% of polybutyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com