Environmentally-friendly lead-free wall paint for children's rooms

A coating and children's technology, applied in anti-corrosion coatings, fire-resistant coatings, starch coatings, etc., can solve problems such as difficult to remove, and achieve the effects of good environmental protection, excellent hand feeling and excellent comprehensive performance.

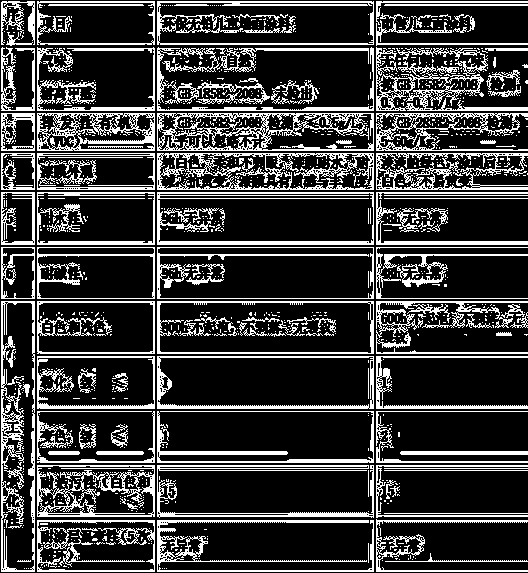

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 200.5 kg of water, 1.0 kg of ephedra alkaloids, 2.5 kg of SN5040 dispersant, 1.0 kg of CF-10 wetting agent, and 1.0 kg of A-10 defoamer into the reaction kettle, at a speed of (500~800) r / min Disperse (10~25) min; then add 120.0kg starch gelatinization solution, 160.5 kg nano-chlorination rutile titanium dioxide, 40.0 kg nano-calcium, and stir at a speed of (800~1500) r / min (10~ 40) min, sanding until the material fineness ≤ 50 μm; then add 190.5 kg of American Celanese CELANESE ATEVA EVA 1608 emulsion, 30.5 kg of vegetable gum, 1.0 kg of A-10 defoamer to the reaction kettle, at a speed of Stir at (300~900) r / min for (10~30) min; finally use 25.5 kg of water and 7.5 kg of vegetable glue to adjust the viscosity so that the viscosity is (100±5) KU at (25±1)°C, 200-mesh sieve, after passing the test, a white flowing liquid is obtained, which is the inventive product.

Embodiment 2

[0035]Add 230.5 kg of water, 1.5 kg of ephedra alkaloids, 4.5 kg of SN5040 dispersant, 1.5 kg of CF-10 wetting agent, and 1.5 kg of A-10 defoamer into the reaction kettle, at a speed of (500~800) r / min Disperse (10~25) min; then add 150.0kg starch gelatinization solution, 190.5 kg nano-chlorination rutile titanium dioxide, 50.0 kg nano-calcium, and stir at a speed of (800~1500) r / min (10~ 40) min, sanding until the material fineness ≤ 50 μm; then add 220.5 kg of American Celanese CELANESE ATEVA EVA 1608 emulsion, 40.5 kg of vegetable gum, 1.5 kg of A-10 defoamer to the reaction kettle, at a speed of Stir at (300~900) r / min for (10~30) min; finally use 30.5 kg of water and 10.5 kg of vegetable glue to adjust the viscosity so that the viscosity is (100±5) KU at (25±1)°C, 200-mesh sieve, after passing the test, a white flowing liquid is obtained, which is the inventive product.

Embodiment 3

[0037] Add 260.0 kg of water, 2.5 kg of ephedra alkaloids, 5.0 kg of SN5040 dispersant, 2.8 kg of CF-10 wetting agent, and 2.5kg of A-10 defoamer into the reaction kettle, at a speed of (500~800) r / min Medium dispersion (10~25) min; then add 170.0kg starch gelatinization liquid, 210.5 kg nano-level chlorinated rutile titanium dioxide, 60.0 kg nano-calcium, and stir at a speed of (800~1500) r / min (10~ 40) min, sanding until the material fineness ≤ 50 μm; then add 260.5 kg of American Celanese CELANESE ATEVA EVA 1608 emulsion, 45.5 kg of vegetable gum, 2.5 kg of A-10 defoamer to the reaction kettle, at a speed of Stir at (300~900) r / min for (10~30) min; finally use 35.5 kg of water and 12.5 kg of vegetable gum to adjust the viscosity so that the viscosity is (100±5) KU at (25±1)°C, 200-mesh sieve, after passing the test, a white flowing liquid is obtained, which is the inventive product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com