A kind of water-based paint composition

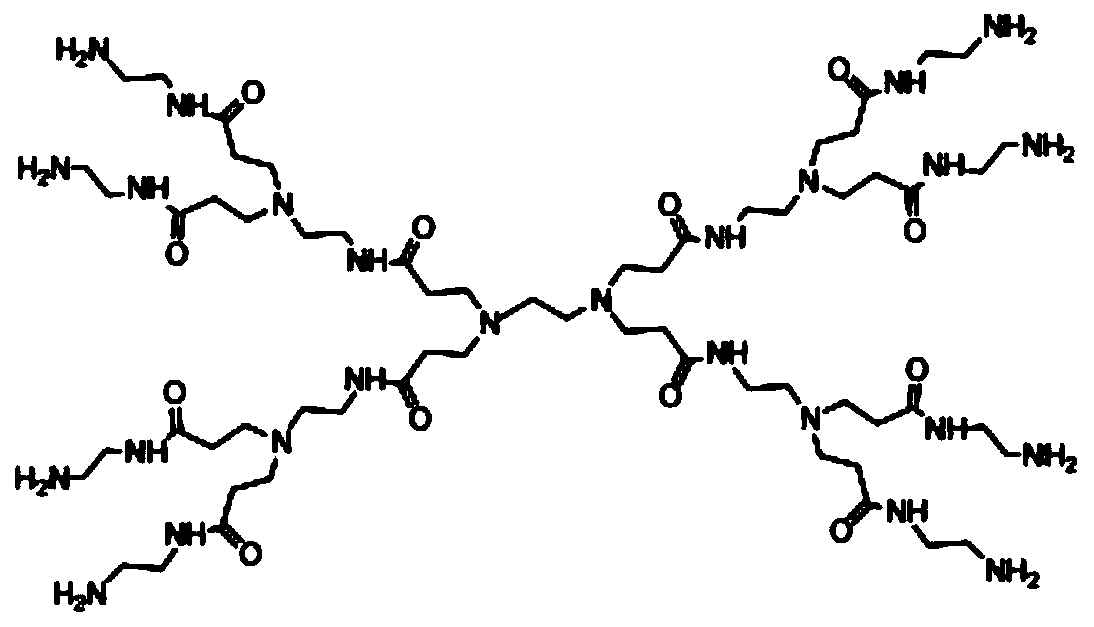

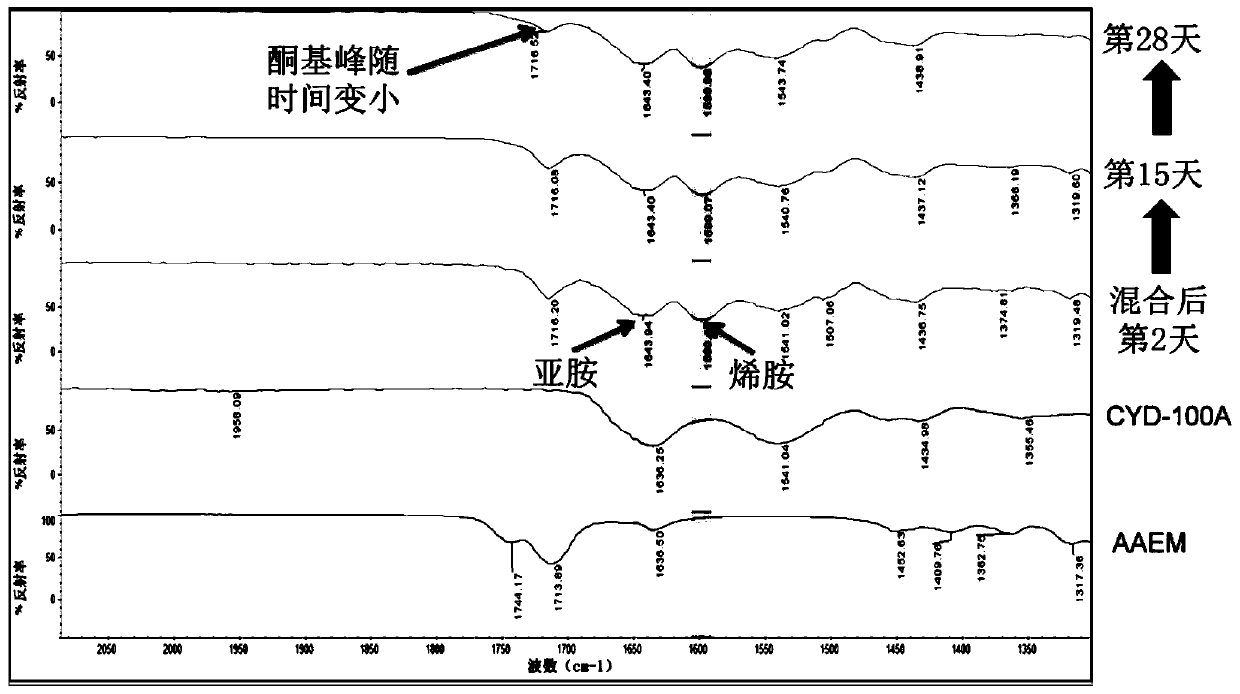

A water-based paint and composition technology, applied in the direction of coating, can solve the problems of the decline of the comprehensive performance of the paint film, the lack of cross-linking and curing of dendritic polymers and hyperbranched polymers, etc., to achieve increased cross-link density and improved water resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

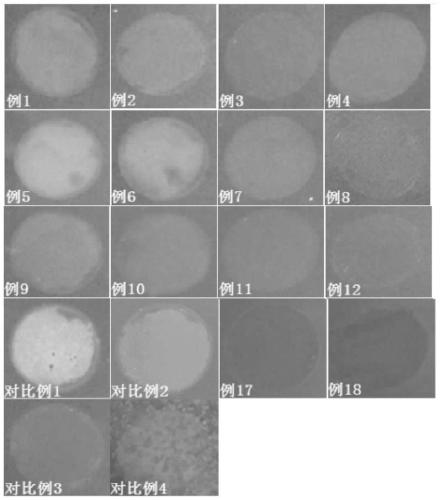

Examples

Embodiment 1

[0063] Prepare the paint varnish containing PAMAM, and the formula is shown in Table 2.

[0064] The preparation method is: at room temperature (20-25°C), add SF240 emulsion into the dispersion tank, control Rotate at 800-1000 rpm, then add CYD-100A, TEXANOL, ethylene glycol and Foamex815N in sequence, and continue to stir for 15 minutes to ensure sufficient mixing to prepare a finished varnish.

Embodiment 2~24

[0066] Prepare the paint varnish containing PAMAM, and the formula is shown in Table 2. Preparation method is all with embodiment 1.

Embodiment 25

[0091] Prepare a PAMAM-free finished paint and name it Paint-X. The preparation method is: add 15wt% (in this embodiment, each component percentage is relative to the total amount of each raw material) deionized water into the dispersion tank, control The rotation speed is 800-1000 rpm, and then the raw materials are 0.4wt% HEC thickener, 0.1wt% pH regulator AMP95, 0.8wt% polycarboxylate sodium salt dispersant, 0.5wt% organosilicon defoamer, Add 21wt% titanium dioxide, 5wt% talcum powder, and 5wt% kaolin into the dispersion tank. When adding, control the time interval between adding each raw material for 2 to 3 minutes to ensure sufficient mixing; increase the speed to 1500-1800 rpm, continue After dispersing for 15-20 minutes, reduce the rotating speed to 500-800 rpm, and then add raw materials in sequence: 36.5wt% SF240 emulsion, 1.5wt% film-forming aid (Eastman OE300), 0.2wt% tank preservative (LanxessPreventol D7 ), 2wt% antifungal agent (Lanxess Biox AM 139), 2wt% PU thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com