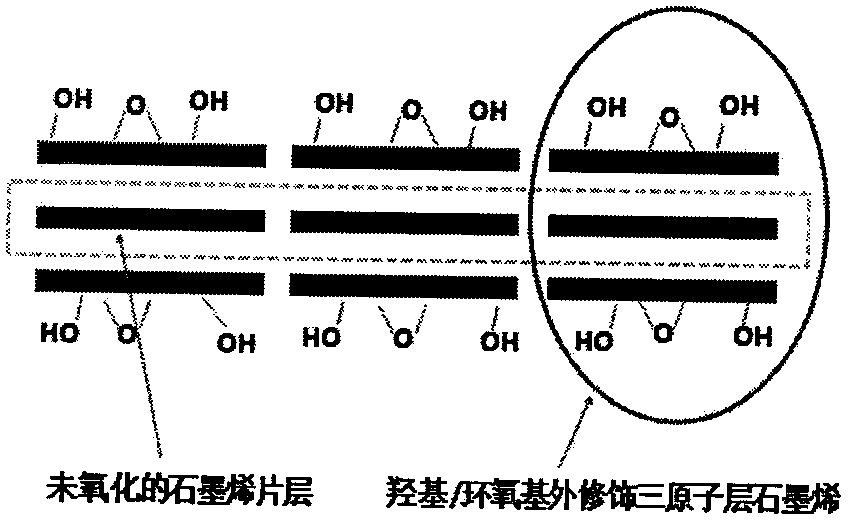

Preparation method of high-conductivity hydroxyl/epoxy group externally modified graphene transparent conductive film

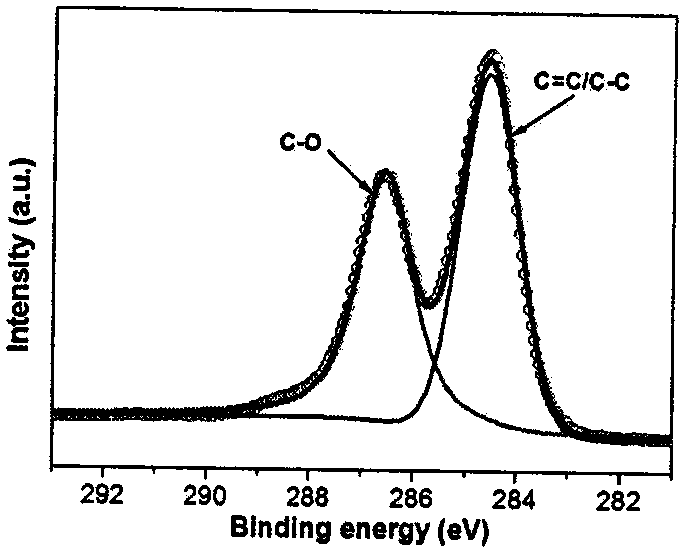

A technology of transparent conductive film and high conductivity, which is applied in the direction of graphene, chemical instruments and methods, and bulk chemical production, etc. It can solve the problems of graphene materials that are difficult to handle, have large structural damage, and high oxygen content, and achieve easy reduction Treatment, the effect of less damage to the sheet structure, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Mix 30g of iodine bromide and 50mg of expanded graphite evenly, fill it with protective gas Ar, seal it in a 50mL glass bottle, place it in an oil bath environment at 100°C, and heat it for 12h to prepare a third-order graphite intercalation compound.

[0026] (2) The graphite intercalation compound was quickly taken out from the glass bottle and filtered.

[0027] (3) Put the intercalation compound into a hydrothermal kettle with a volume of 50 mL rapidly.

[0028] (4) Add 10 mL of aqueous solution into the hydrothermal kettle, and quickly fix the hydrothermal kettle equipment.

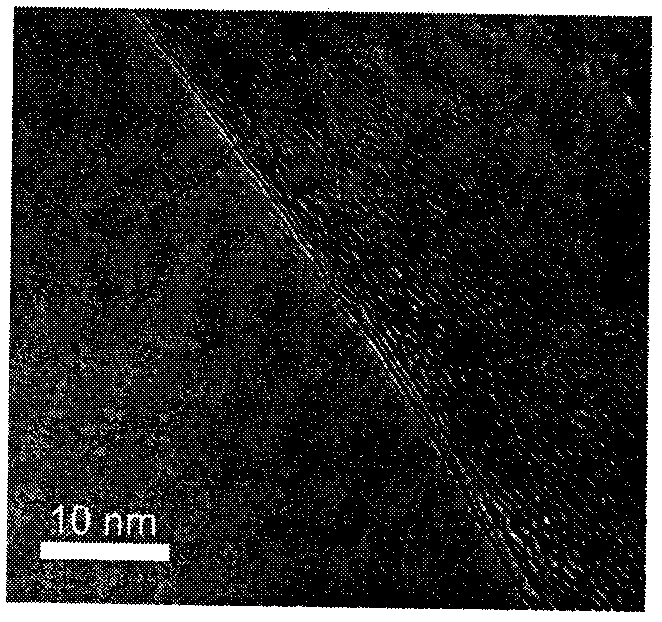

[0029] (5) Heat the hydrothermal kettle to 180° C. and keep it for 1 hour. After the reaction is completed, take out the sample and clean the sample to obtain a three-atom layer high-quality graphene powder aggregate.

[0030] (6) 20mL H 2 SO 4 Maintained in ice water (0°C) for 0.5 hours.

[0031] (7) Add 30 mg of the original graphene material into concentrated sulfuric acid, and stir...

Embodiment 2

[0041] (1) Mix 30g of iodine bromide and 50mg of expanded graphite evenly, fill it with protective gas Ar, seal it in a 50mL glass bottle, place it in an oil bath environment at 100°C, and heat it for 12h to prepare a third-order graphite intercalation compound.

[0042] (2) The graphite intercalation compound was quickly taken out from the glass bottle and filtered.

[0043] (3) Put the intercalation compound quickly into a supercritical water device with a volume of 50 mL.

[0044] (4) Add 2 mL of aqueous solution to the supercritical water device, and quickly fix the device.

[0045](5) Heat the hypersupercritical water device to 180° C., raise the pressure to 22.1 Mpa, and keep it for 1 hour. After the reaction is completed, take out the sample and clean the sample to obtain graphene powder aggregates.

[0046] (6) 20mL H 2 SO 4 Maintained in ice water (0°C) for 0.5 hours.

[0047] (7) Add 30 mg of the original graphene material into concentrated sulfuric acid, and sti...

Embodiment 3

[0054] (1) 0.3g anhydrous FeCl 3 Mix with 0.05g of expanded graphite, seal in vacuum, heat up to 380°C for 1h, and maintain for 12h to prepare a third-order graphite intercalation compound.

[0055] (2) Dissolve the graphite intercalation compound in dilute hydrochloric acid solution, filter and dry with suction, and set aside.

[0056] (3) Put the graphite intercalation compound into supercritical CO with a volume of 50mL rapidly 2 device.

[0057] (4) to supercritical CO 2 Add 5mL of 30% hydrogen peroxide solution into the device, and quickly fix the device.

[0058] (5) the high supercritical CO 2 The device is heated to 38°C, the pressure is increased to 75atm, and kept for 1 hour. After the reaction is completed, the sample is taken out, and the sample is cleaned to obtain graphene powder aggregates.

[0059] (6) 20mL H 2 SO 4 Maintained in ice water (0°C) for 0.5 hours.

[0060] (7) Add 30 mg of the original graphene material into concentrated sulfuric acid, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com