Method for preparing aluminum polychloride from gasification slag

A technology of polyaluminum chloride and gasification slag, which is applied to aluminum chloride, aluminum halide and other directions, can solve the problems of large addition amount of aluminum source, low economic and environmental benefits, difficult alumina dissolution process, etc., and achieves low production cost. , The effect of low impurity content and high operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

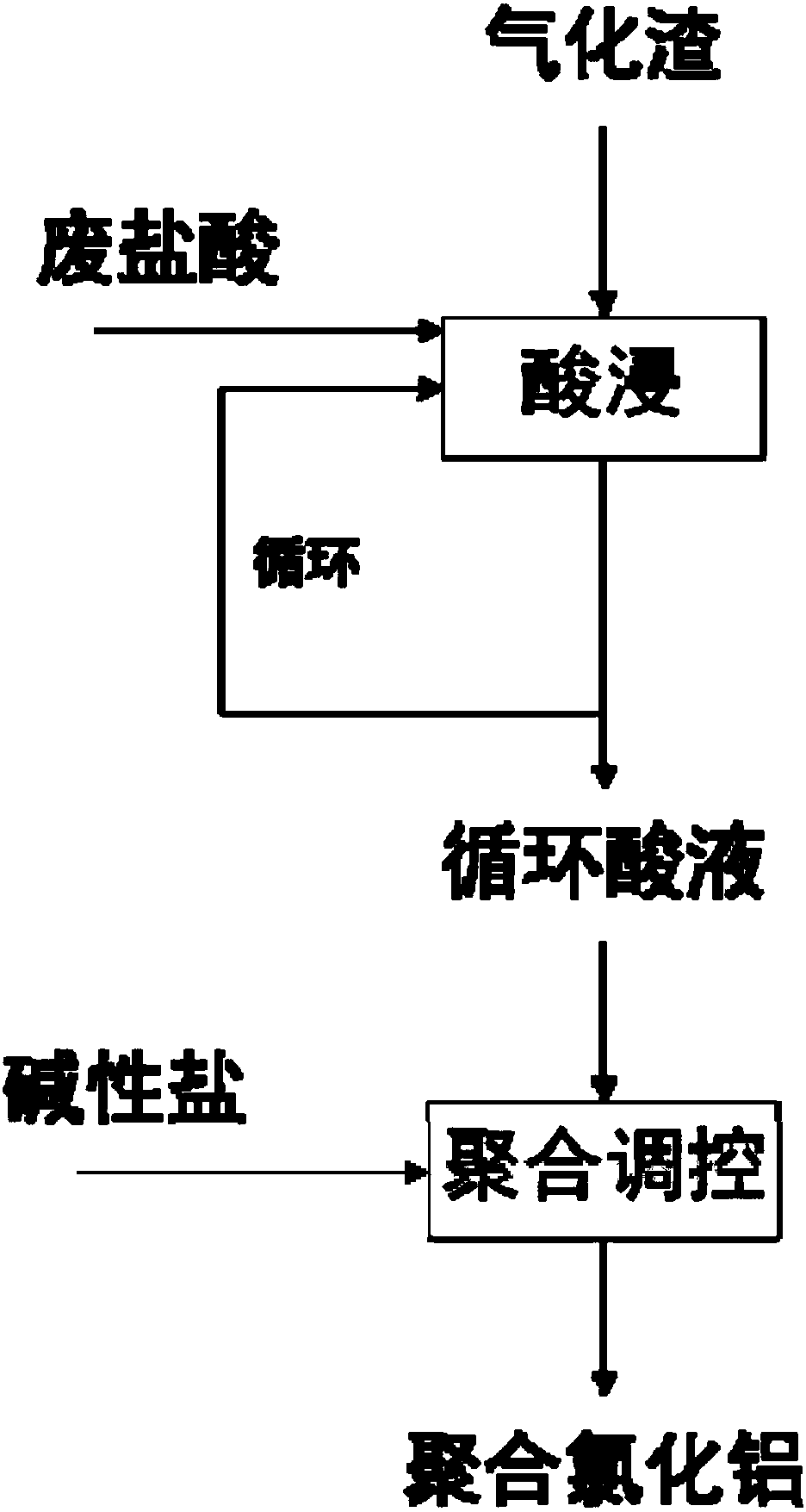

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing polyaluminum chloride by utilizing gasification slag, comprising the steps of:

[0051] Dissolution process: Gasification slag and industrial by-product hydrochloric acid are used for mixed reaction according to the liquid-solid ratio of 4:1. The concentration of hydrochloric acid is 200g / L, the reaction temperature is 95°C, the reaction time is 120min, and the rotation speed is 350r / min; the reaction is over Afterwards, obtain filtrate through solid-liquid separation;

[0052] Circulation process: add fresh industrial by-product hydrochloric acid (30% by mass) to the above filtrate to prepare the required volume (reaching a liquid-solid ratio of 4:1 during leaching), carry out the above acid leaching process, repeat the above process, and cycle 6 times, filter to obtain aluminum-rich solution, wherein the alumina content (mass percentage composition) is as high as 8.3%;

[0053] Polymerization control: add high-calcium fluidized bed fly ash (mas...

Embodiment 2

[0056] A method for preparing polyaluminum chloride by utilizing gasification slag, comprising the steps of:

[0057] Dissolution process: Gasification slag and industrial by-product hydrochloric acid are used for mixed reaction according to the liquid-solid ratio of 6:1, the concentration of hydrochloric acid is 220g / L, the reaction temperature is 85°C, the reaction time is 180min, and the rotation speed is 350r / min; the reaction is over Afterwards, obtain filtrate through solid-liquid separation;

[0058] Circulation process: add fresh industrial by-product hydrochloric acid (30% by mass) to the above-mentioned filtrate to prepare the required volume (reaching a liquid-solid ratio of 6:1 during leaching), carry out the above acid leaching process, repeat the above process, and cycle 7 times, filter to obtain aluminum-rich solution, wherein the alumina content (mass percentage composition) is as high as 7.8%;

[0059] Polymerization control: add industrial waste phosphorus s...

Embodiment 3

[0062] A method for preparing polyaluminum chloride by utilizing gasification slag, comprising the steps of:

[0063] Dissolution process: Gasification slag and industrial by-product hydrochloric acid are used for mixed reaction according to the liquid-solid ratio of 6:1. The concentration of hydrochloric acid is 200g / L, the reaction temperature is 95°C, the reaction time is 180min, and the rotation speed is 350r / min; the reaction is over Afterwards, obtain filtrate through solid-liquid separation;

[0064] Circulation process: Add fresh industrial by-product hydrochloric acid (30% by mass) to the above filtrate to prepare the required volume (reaching a liquid-solid ratio of 6:1 during leaching), carry out the above acid leaching process, repeat the above process, and cycle 9 After several times, filter to obtain aluminum-rich solution, wherein the alumina content (mass percentage composition) is as high as 8.2%;

[0065] Polymerization control: add industrial waste phosphor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com